Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Numerical Control

Part Programming with APT

Part Programming

with APT

In this

section, we present some of the basic principles and vocabulary of the APT

language. APT is an

acronym that stands for Automatically Programmed Tooling. It is a

three dimensional NC part programming system that was developed in the late

19508 and early 60s (Historical Note 6.3). Today it remains an important and

widely used language in the United States and around the world. APT is also

important because many of the concepts incorporated into it termed the basis

for other subsequently developed languages. APT was originally intended as a

contouring language. but modern versions can be used for both point to point and

contouring operations in up to five axes. Our discussion will be limited to the

three linear axes, x, y, and z.APT can be used for a variety of

machining operations.

Our

coverage will concentrate on drilling (point to point) and milling (contouring)

operations. There are more than 500 words in the APT vocabulary. Only a small

(but important) fraction of the total lexicon will be covered here. The

Appendix to this chapter lists some of these important APT words.

The

reader must remember that the work described in this historical note was

started in the 1950s,a lime when digital computer technology was in its

infancy, and so were the associated computer programming languages and methods.

The APT project was a pioneering effort, not only io the development of NC

technology, but also in computer programming concepts, computer graphics, and

computeraided design (CAD).

It was

recognized early in the NC development research at MIT that part programming

would be a timeconsuming task in the application of the new technology, and

that there were opportunities to reduce the programming time by delegating

portions of the task to a genetaI_purpo.e computer. In June 1951, even before

the first experimemal NC machine was operating, a study was undertaken to

explore how the digital computer might be used as a programming aid. The result

of this study was a recommendation that a set of computer programs be developed

to perform the mathematical computations that otherwise would have to be

accomplished by the part programmer. In hindsight, the drawback of this

approach was that, while it automated certain steps in the part programming task,

the basic manual programming procedure was preserved

The

significant breakthrough in computerassisted part programming was the

development of the automatically programmed 1001 system (APT) during the years

19561959. It was the brainchild of mathematician Douglas Ross, who worked in

the MIT Servomechanisms Lab at the time. Ross envisioned a part programming

system in which (1) the user would prepare instructions for operating the

machine tool using Englishlike words, (2) the digital computer would translate

these instructions into a language that the computer could understand and

process. (3) the computer would carry out the arithmetic and geometric

calculations needed to execute the instructions. and (4) the computer would

further process (postprocess) the instructiOn! 'u that they could be

interpreted by the machine tool controller. He further recognized that the

programming system should be expandable for applications beyond those

considered in the immediate research (milling applications).

Around

this time, the Aircraft Industries Association (AlA, renamed the Aerospace

Industries Assoclation in 1959) was attempting to deal with NC part programming

issues through its Subcommittee on Numerical Control (SNC). Ross was invited 10

attend a meeting of the SNC in January 1957 to present his views on

computerassisted part programming. The result 01 this meeting was that Rosa's

work at MIT was established as a focal poinl for NC programming within thc AlA,

A project was initiated in Apri11957to develop a twodimensionill version of

APT, with nine alrcrafr companies plus IBM Corporation participating in the

joint effort ami MIT as project coordinator. The 2DAPT system was ready for

field evaluation at plant, of participating companies in April 1958.Testing,

debugging, am] refining the programming system took approximately three

years.during which time the AlA assumed responsibllity for further APT

development. In 1961, the Illinois Institute of Technology Rcsearch lnslituto;

(lITRl) was selected by the AlA to become the agency responsible

for longrange maintenance and upgrading of Al'T'In 1962,IITRI announced

completion of APTIII. a commercial version 01APT for threedimensional part

programming. In 1974,APT was accepted as the U.S.standard for programming NC

metal cutting machine tools. In 1978,it was accepted by the ISO as the

international standard.

One of

the initial problems with APT when it was released in the early 1960swas that a

very large computer was required 10execute it, thereby limiting the number of

companies that could use it Several part programming languages based directly

on APT were developed to address this problem. Two of the more important

APTbased languages were ADAPT and EXAPT. ADAPT (ADaptation of APT) was

developed by IBM under Air Force contract to include many of the features of

APT bUI required a much smaller computer. ADAPT can be used for both

pointtopoint and contouring jobs. EXAPT (EXtended subset of APT) was anolher NC

part programming language based on APT. EXAPT was developed in Germany around

1964in three versions',(1) EXAPT I was designed for pointtopoint applications,

such as drilling and straight milling; (2) EXAPT 11was developed for turning

operations; and

(3) EXAPT

III was capable of limited contouring for milling.

APT is

not only a language; it is also the computer program that processes the APT

statements to calculate the corresponding cutter positions and generate the

machine tool control commands. To program in APT. the part geometry must first

be defined. Then the tool is directed to various point locations and along

surfaces of the workpart to accomplish the required machining operations. The

viewpoint of the programmer is that the workpiece remains stationary and the

tool is instructed to move relative to the part. To complete the program,

speeds and feeds must be specified, tools must be called, tolerances must be

given for circular interpolation, and so forth. Thus, there are four basic

types of statements in the APT language:

Geometry

statements, also called

definition statements, are used to define the geometry elements that

comprise the part.

Motion commands

are used to specify the tool path.

Post-processor

statements control the machine tool operation, for example, to

specify speeds and feeds, set

tolerance values for circular interpolation, and actuate other capabilities of

the machine tool.

Auxiliary statements, a group

of miscellaneous statements used to name the part program, insert comments in

the program and accomplish similar functions.

These

statements arc constructed of APT vocabulary words, symbols. and numbers, all

arranged using appropriate punctuation. APT vocabulary words consist of six or

fewer characters. 1 he characters are almost always letters of the alphabet.

Only a very few APT vocabulary words contain numerical digitsso few in fact

that we will not encounter any of them in our treatment of APT in this chapter.

Most APT statements include a slash (I) as part of the punctuation. APT

vocabulary words that immediately precede the slash arc called major words. whereas those that follow

the slash are called minor words.

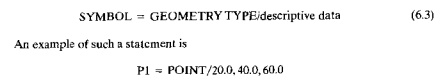

Geometry Statements. The

geometry of the part must be defined to identify the surfaces and features that are to be machined. Accordingly, the

points, lines, and surfaces must be defined in the program prior to specifying

the motion statements. The general form of an APT geometry statement is the

following:

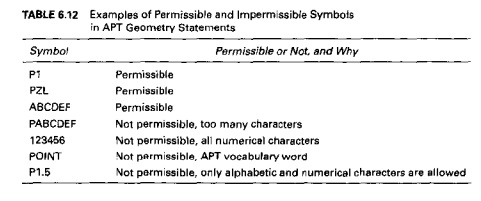

An APT

geometry statement consists of three sections. The first is the symbol used to

identify the geometry element. A symbol can be any combination of six or fewer

al phabetical and numerical characters, at least one of which must be alphabetical.

Also, the symbol cannot be an APT vocabulary word. Some examples are presented

in Table 6.12 to illustrate what is permissible as a symbol and what is not.

The second section of the APT geometry statement is an APT major word that

identifies the type of geometry element. Examples are POINT, LINE, CIRCLE, and

PLANE. The third section of the APT geometry statement provides the descriptive

data that define the element precisely, completely, and uniquely. These data

may include numerical values to specify dimensional and position data,

previously defined geometry dements, and APT minor words.

Punctuation

in an APT geometry statement is indicated in Eq. (6.3). The definition

statement is written as an equation, the symbol being equated to the geometry

element type, followed by a slash with descriptive data to the right of the

slash. Commas are used

to

separate the words and numerical values

in the descriptive data.

There arc

a variety of ways lu spectry the various geometry elements. The Appendix to

this chapter presents a sampling of statements for defining the geometry

elements we

will be

using in our treatment of APT: poiuts.Iines, planes, and circles. The reader

may benefit from a few examples:

Points.

PI

"' POINI!2IJ.U,40.U,60.0

where the

descriptive data following the slash indicate the X·, yo, and zcoordinates.

The specification can be done in either inches or millimeters (metric). We use

metric values in our examples. As an alternative, a point can be defined as the

intersection of two mtersecrmg lines, as in the following

P2 =

POINTfINTOF, Lt. L2

where the

APT word INTOF in the descriptive data stands for "intersection of."

Other methods of defining points are given in the Appendix under POINT

Lines.

A line

defined in APT is considered to be of infinite lengtb in hoth directions. Also, APT

treats a line as a vertical plane that is perpendicular to the .rj' plane. The

easiCStway to specify a line is by two points through which it passes:

L3 = LINE/P3. P4

In some

situations, the part programmer may find it more convenient to define a new

line as being parallel to another line that has been previously defined; for

example,

L4 =

LlNEIP5, PARLEL, L3

where

PARLEL is APT's way of spelling "parallel."The statement indicate,

line l4 passes through point PS and is parallel to line L3.

Planes.

A plaue

can be defined by specifying three points through which the plane passevasin

the following'

PLl =

PLANE/Pl.P2,P3

Of

course. the three points must he noncollinear. A plane can also be defined as

being parallel to another plane that has been previously defined; for instance,

PL2 =

PLANE!P2, PARLEL, PLl

which

states that plane PL2 passes tbrough point P2 and is parallel to plane PLI. In

APT, a plane extends indefinitely.

Circles. In APT, a circle is considered to be a cylindrical surface that

is pcrpendic

ular to

the xj plane and extends to infinity in the zdircction. The easiest way to

define a circle i~ by its

center and radius. as in the following

Cl = CIRCLE/CENTER,Pl,RADIUS,25.0

By

convention. the circle is located in the .e.y plane. An alternative way of

defining a circle i~to

specify thur it passes through three points; for example,

C2 = CIRCLE/P4, P5, P6

where the

three points must not he collinear There are m;'lny other ways to define a ciretc, several of which are listed in the

Appendix under CIRCLE

Certain ground rules

must he obeyed when formulating APT geometry statements.

Following are four important APT rules:

t. Coordinate data must be specified in the order x, then y, then z, because the statement

PI = POINT/20.5,40,O,60.0

is

interpreted to mean x =

20.5 mm,y =

40.0 mm.

and e = 60.0 mm

Any

symbols used as descriptive data must have been previously defined; for example.In

the statement

P2 = POINT/JNTOF,Ll,L2

the two

lines Ll and L2 must have been previously defined. In setting up the list of

geometry statements, the APT programmer must be sure to define symbols before

using them in subsequent statements.

A symbol

can be used to define only one geometry element. The same symbol cannot be used

to define two different elements. For example. the following statements would

be incorrect if they were included in the same program:

Pl = POINTI20,40,60

PI = POINT 130,50,70

Only one

symbol can be used to define any given element. For example, the following two

statements in the same r"rt program would be incorrect;

PI =

POINTI20,40,60

P2 =

POINT/20,40,60

EXAMPLE 6.3 Part Geometry Using APT

Let us

construct the geometry of our sample part in Figure 6.15. The geometry dements

of the part to be defined in APT are labeled in Figure 6.18. Reference is also

made to Figure 6.16, which shows the coordinate values of the points used to

dimension the part. Only the geometry statements are given in the APT sequence

that follows:

PI = POINT 10,0,0

P2 = POiNT/160.0,O,O

P3 = PUINT /160.0.60.0,0

P4 =

POINT/35.0.90.0.0

P5 = POINT/70.0.30.0.0

P6 = POINT/120.0.30.0,0

P7 =

POINT /70.0.60.0,0

P8 =

POINT /130.0.60.0,0

L1 = LINE/Pl,P2

L2 = LINE/P2, P3

Cl =

CIRCLE/CENTER, P8, RADIUS. 30.0

L3 = L1NE/1'4, PARLEL, L1

L4 = LINE/P4, PI

Motion Commands. All APT

motion statements follow a common fonnat,just as geometry statements have their own format. The format of an APT

motion command is'

MOTION COMMAND/descriptive data (6.4)

An

example of an APT motion statement is

GOTOIPI

I'he

statement consists of two sections separated by a slash. The first section is

the basic command that indicates what move the tool should make. The

descriptive data following the slash tell the tool where to go. In the above example, the tool is

directed to go to (GOTO) point PI, which has been defined in a previous

geometry statement.

At the

beginning of the sequence of motion statements, the tool must be given II starting point. This is likely

to be the target point. the location where the operator has positioned the tool

at the start of the job.The part programmer keys into this starting position

with the following statement:

fROM/PTARG {651

where

FROM is anAPT vocabulary word indicating that this is the initial point from

which all others will be referenced; and PTARO is the symbol assigned to the

starting point. Another way to make this statement is the following'

FROMj20.0. 20.0,0

where the

descriptive data in this case arc the X, y, and zcoordinates of the starting point. The FROM statement

occurs only at the start of the motion sequence.

In our

discussion of APT motion statements, it is appropriate to distinguish between pointtopoint motions and contouring

motions. For potnrtopoiru motions,

there are onl two commands: GOTQ and GODLTA.The GOTO statement instructs the

tool to go to a particular point location specified in the descriptive data.

TWo examples are:

GOTOIP2 (6.6,)

001'0/25.0,40,0,0 (6.6b)

In the

first command, P2 is the destination or the too] point. In the second command,

the 1001 has been instructed to go to the location whose coordinates are x =

25.0, Y = 40.0, and z = O.

The

GODLTA command specifies an incremental move for the tool.To illustrate, the

following statement instructs the tool to move from its present position by a

distance of 50.0 mm in the xdirection, 120.0 mm in the ydirection, and 40 rum

in the zdirection

GODLTA!50.0, 120.0, 40.0

The GODLY

A statement is useful in drilling and related machining operations. The tool

can be directed to go to a given hole location; then the GODLTA command can be

used to drill the hole, as in the following sequence:

GOTO/P2

GODLTA/[), 0, 50.0

GODLTAjO,0,50.0

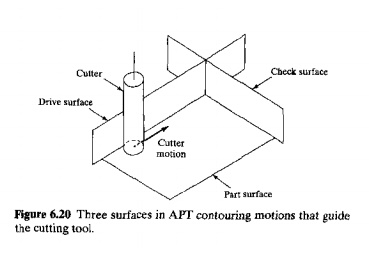

Contouring

motion commands are more complicated than PTP commands are because the tool's

position must be continuously controlled throughout the move. To exercise this

control. the tool is directed along two intersecting surfaces until it reaches

a third surface, as shown in Figure 6.20. These three surfaces have specific

names in APT; they are:

Drive surface. This is the surface that

guides the side of the cutler. It is pictured as II plane in our figure.

Part surface. This is the surface, again

pictured as a plane, on which the bottom or nose of the tool is guided.

Check;

surface. This is the surface that stops the forward motion of the tool in the

execution of the current command. One might say that this surface

"checks" the advance of the tool.

It should

be noted here that the "part surface" mayor may not be an actual

surface of the part The part programmer may elect to use an actual part surface

or some other previously defined surtace for the purpose of maintaining

continuous path control of the tool. The same qualification goes for the drive

surface and check surface.

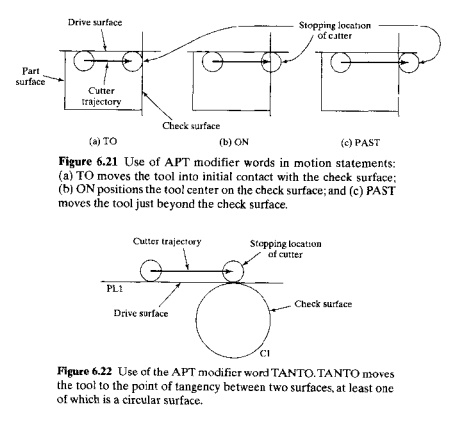

There are

several ways in which the check surface can be used. Ifus is determined by

using any of four APT modifier words in the descriptive data of the motion

statemen!. The four modifier words arc TO, ON, PAST. and TANTO. As depicted in

Figure 0.21, the word TO positions the leading edge of the tool in contact with

the check surface; ON positions the center of the tool on the check surface;

and PAST puts the tool beyond the check surface. so that its trailing edge is

in contact with the check surface. The fourth modifier word TANTO is used when

the drive surface is tangent to a circular check surface, as in Figure 6.22.

TANTO moves the cutting tool to the point of tangency with the circular surface

An APT

contouring motion command causes the cutter to proceed along a trajectory

defined by the drive surface and part surface; when the tool reaches the check

surface it stops according to one of the modifier words TO, ON, PAST, or TANTO.

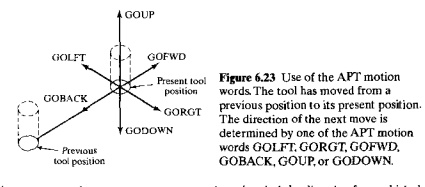

In writing a

Figure 6.23

Use of the APT motion words. The tool has moved from a previous position

10 its present position. The

direction of the next move is

determined by one of the APT motion

words GOLFT. GORGT, GOFWD, GOBACK, GDUP,

or GODOWN.

motion

statement, the part programmer must keep in mind the direction from which the

tool is coming in the preceding motion command. The programmer must pretend to

be riding on top of the tool, as if driving a car. After the tool reaches the

check surface in the preceding move, does the next move involve a right tum or

left tum or what? The answer to this question is determined by one of the

following six motion words, whose interpretations are illustrated in Figure

6.23:

GOLIT commands

the tool to make a left tum

relative to tbe last move.

GORGT commands

the tool to make a right tum relative

to the last move.

GOFWD commands

the tool to move forward relative

to the last move.

GOBACK commands

the tool to reverse

direction relative to the last move.

GOUP commands

the tool to move upward

relative to the last move

GODOWN commands

the tool to move down relative to

the last move.

In many

cases, the next move will be in a direction that is a combination of two pure

directions. Forexample, the direction might be somewhere between go forward and

go right. In these cases, the proper motion command would designate the largest

direction component among the choices available.

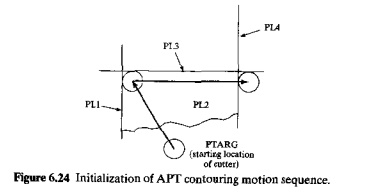

To begin

the sequence of motion commands, the FROM statement,Eq. (6.5) is used in the

same manner as for pointtopotnt moves. The statement following the FROM command

defines the initial drive surface. part surface, and check surface. With

reference to Figure 6.24. the sequence takes the following form:

FROMiPTARO

oo/ro,

flLl, TO. PL2, TO PL3 (6.7)

The

symbol PTAR.G represents the target point w~ere the ?perator has. set up the

tool. The GO command Instructs the tool to move to the mtersecnon of the drive

surface (PL1), the part surface (PL2), and the check surface (PL3). Because the

modifier word TO has been used for each of the three surfaces, the

circumference of the cutter is tangent to PLI and PL3. and the bottom of the cutler

is on PL2. The three surfaces included in the GO statement must be specified in

the order: (I) drive surface, (2) part surface, and (3)checksurlacc

Note that

GO/TO is not the same as the 001'0 command. Eq. (6.6). 001'0 is used only for

JYrp motions. The GO/ command is used to initialize a sequence of contouring

motions and may take alternative forms such as GO/ON, GorrO, or GOIPAST.

After

initia'ization, the tool is directed along its path by one of the six motion

command words. It is [Jot necessary to redefine the part surface in every

motion command after it has been initially defined as long as it remains the

same in subsequent commands. In the preceding motion command, Pq. (6.7), the

cutter has been directed from P"IARG to lhe interscction of surfaces PLI,

PL2, and PL3. Suppose it is now desired to move the tool along planc PL3 in

Figure 6.24, with PL2 lCllw.i"ing a~ the pan surface. The following

command would accomplish this motion:

GORGT!PL3, PAST,PL4

Note that

PL2 is not mentioned in this new command. PD, which was the check surface in

the preceding command, Eq. (6.7), is the drive surface in the new command. And

the new check surface is PL4. Although the part surface may remain the same

throughout the motion sequence. the drive surface and check surface must be

redefined in each new contouring motion command.

There arc

many parts whose features can all be defined in two axes, x and y. Although such

parts certainly possess a third dimension, there are no features to be machined

in this direction. Our sample part is a case in point. In the engineering

drawing, Figure 6.15, the sides of the part appear as lines, although they lire

threedimensional surfaetls on the physical part. In cases like this, it is more

convenient for the programmer to define the pan profile in terms of lines and

circles rather than planes and cylinders. Fortunately, the APT language system

allows this because in APT, lines me treated as planes and circles are treat.

ed as cylinders, which are both perpendicular to the ry plane. Hence, the planes around the part outline in Figure 6.15

can be replaced by lines (call them Ll, L2, L3, and L4), and the APT commands

in Bqs (6.7) and (6.8) can be replaced by the following:

fROM/PTARG

oo/ro. Ll,

TO, PL2, TO L3

GORGT/L3, PAST,L4

Substitution

of lines and circles for planes and cylinders in APT is allowed onlv when the

sides of the pall are perpendicular to the xy

plane. Note that plane PL2 has not been converted to a line. As the "part

surface" in the motion statement, it must maintain its status as a plane

parallel to the .r and yaxes,

EXAMPLE 6.4 APT Contouring Molion Commands

Let

U~write the AM' motion commands to profile mill the outside edges of our sample

workpart. The geometry clements are labeled in Figure 6,18, and the too! path

is shown in Figure 6.17. The tool begins its motion sequence from a target

point PTARG located at x = 0, y = 50 mm and l = 10 rnm. We also assume that

"part surface" PL2 has been defined as a plane parallel to the xy

plane and located 25 mm below the top surface of the part (Figure 6.16), The

reason for defining it this way is to ensure that the cutter will machine the

entire thickness of the part.

FROMlPTARG

GO/TO. L1, TO, PL2. ON,L4

GORGT/Lt, PAST, L2

GOLFTfL2, TANTO,

Cl

GOFWDtCL PAST. L3

GOFWD/L3, PAST, L4

GOLFf/L4, PAST, L1

GOTO/PO

Postprocessor and

Auxiliary Statements. A complete APT

part program must

include

functions not accomplished by geometry statements and motion commands. These

additional functions are implemented by postprocessor statements and auxiliary

statements.

Postprocessor

s[{]/emenls control the operation of the machine tool and playa supporting role

in generating the tool path. Such statements are used to define cutter size,

specify

speeds and feeds, turn coolant flow on and off,

and control other features of

the par

ticular machine

tool on which the machining job will be performed. The general form of a

postprocessor statement

is the following:

POSTPROCESSOR COMMAND/descriptive data

(6.9)

where the

POSTPROCESSOR COMMAND i~an APT major word indicating the type of function or

action to be accomplished, and the descriptive data consists of APT minor words

and numerical values. In some commands. the descriptive data is omitted. Some

exarnples of postprocessor statements that appear in the Appendix at the end of

the chapter arc the following:

llNITSiMM

indicates that the specified units used in the program an: INCHES

or Mlv1.

INTOL/O.02 specifies

inward tolerance for circular

interpolation.

OUTTOLjO.02 specifies

outward tolerance for circular

interpolation.

eUTTERj20.0 defines cutter diameter for

tool path offset calculations; the length and other dimensions of the tool can

also be specified, if necessary, for threedimension, at machining.

SPINDLjlOOO, CLW specifies spindle

rotation speed in revolutions per minute. Either CLW (clockwise) or eeLW

(counterclockwise) can be specified

SPINDLIOFF stops

spindle rotation.

FED RAT /

40, IPM specifies feed rate in millimeters per minute or inches per minute.

Minor words IPM or IPR are used to indicate whether the feed rate is units per

minute or units per revolution of the cutter, where the units are specified as

inches or millimeters in a preceding UNITS statement.

RAPID engages

rapid traverse (high feed rate) ror nexc movers}.

COOLNT/FLOOD turns CUlling fluid

on

LOADTL/Ol

used with automatic toolchangers to identify which cutting tool should be

loaded into the spindle

DELAY /30

temporarily stops the machine

{Qol [or a period specified in seconds.

Auxiliary slatfment.~ are used

to identify the part program, specify which postprocessor to usc. insert remarks into the program, and so on. Auxiliary

statements have no effect on the generation of tool path. The following APT

words used in auxiliary statements are defined in the Appendix:

PARTNO is

the first statement in an APT program, used to identify Ihe program; fUI example,

PARTNO SAMPLE PART r:UMBER ONE

MACHIN!

permits the part programmer to specify the postprocessor, which in effect

specifies the machine tool.

CLPRJ\T

stands for "cutter location print," which is used to print out the

cutter location sequence

REMARK is

used to insert explanatory comments into the program that are not interpreted

or processed by the APT processor.

FINl indicates

the end of an APT program.

The major

word MACHIN reqnires a slash (I) as indicated in our list above, with

descriptive data that idemify the postprocessor to be used. Words such as

CLPRNT and FINI are complete without descriptive data. PAKTNO and REW.ARK have

a format that is an exception to the normal APT statement structure. These are

words that are followed by descriptive data, but without a slash separating the

APT word from the descriptive data. PARTNO ts used at the very beginning of the

part program and is followed by a series of alphanumeric characters that label

the program. REMARK permits the programmer to insert comments that the APT

processor does not process,

Some

APT Part Programming Examples. As examples of APT, we will

prepare two part programs for our sample part, one to drill the three holes and

the second to profile mill the outside edges. As in our example programs in

Section 6.5.2, the starting workpiece is an aluminum plate of the desired

thickness, and its perimeter has been rough cut slightly oversized in

anucipauon uf the profile millillg operation. Tn effect, these APT programs

will accomplish the same operations as previous Examples 6.1 and 6.2 in which

manual part programming was used.

EXAMPLE 6.5 Drilling

Sequence in APT

let us

write the APT program to perform the drilling sequence for our sample part in

Figure 6.15. We will show the APT geometry statements only for the three hole

locations, saving the remaining elements of geometry for Example 6.6

PARTNO

SAMPIF PART DRILLING OPERATION

MACHINIDRILL,01

CLPRNT

UNITS/MM

REMARK Part geometry. Points are defined 10 mm above part surface.

PTARG = POINT/0,50.0, 10.0

P5 =

POINT /70.0,30.0,10.0

P6 = POTNT/120.0,3D.O, 10.0

P7 = POINT/70.0,60J1, 10.0

REMARK

Drill bit motion statcmenh

FROM/PTARG

RAPID

GOTO/P5

SP1NDL/tOOO, CLW

FEDRAT/O.05, TPR

GODLlA/O,O, 25

GODLTAjO,0, 25

RAPID

GOTO/P6

SPINDL/1OOO, CLW

FEDRAT/O.05, IPR

GODLTAIO,O, 25

GODLTA/o,0, 25

RAPID

GOTOIP7

SPTNDL/l000, CLW

FED RAT 10.05, IPR

GODLTAjO,O,25

GODLTA/O, 0,

25

RAPID

GOTO/PTARG

SPINDUOFF

FINl

EXAMPLE 6.6 TwoAxis Profile Milling in APT

The three

holes drilled in Example 6.5 will be used for locating and holding the work

part for milling the outside edges. Axis coordinates are given in Figure 6.i6.

The top surface of the part is 40 mm above the surface of the machine table. A

20mm diameter end mill with four teeth and a side tooth engagement of 40 mm

will be used. The bottom tip of the cutter will be positioned 25 mm below the

top surface during machining, thus ensuring that the side cutting edges of the

cutter will cut the full thickness of the part. Spindle speed « 1000 rev/min and feed rate = 50 mm/min. The tool path, shown

in Figure 6.17, is the same as that followed in Example 6.2.

PARTNO SAMPLE PART

MILLING OPERATION

MACHIN/MILLING,02

CLPRNT

UNITS/MM

CUTTER/20.0

REMARK

Part geometry. Points and lines are defined 25 nun below part top surface

PTARG = POlNT/O.SO.O,lO.O

PI = POINT

/0,0, 25

P2 = POINT/I60,0,25

P3 =

POINT /160,60,25

P4 POINT/35,90,25

P8 =

POINT/130.60,25

Ll = LINE/PI, P2

L2 =

LINE/P2, P3

CI = CIRCLE/CENTER, P8. RADIUS, 30

L3 =

LINE/P4,LEFf,TANTO,CI

L4 = LINEIP4, P1

PLl = PLANE/PI, P2. P4

REMARK Milling

cutter motion statements.

FROM/PTARG

SPINDL/1000, CLW

FFDRAT /50, IPM

GO/TO.L1,TO,PLl, ON,L4

GORGT/Ll, PAST. L2

GOLFr/L2. TANTO, (:1

GOFWDiC I, PAST, U

GOF\vO/Ll, PAST, L4

GOLFTIL4, PAST, L1

RAPID

GOTOiPTARG

SPINOLfOFF

FINI

Related Topics