Chapter: Basic Electrical and electronics : Electric Circuits and Measurements

Electrical Instruments and Classification of instruments

Measuring Instruments

Classification of instruments

(i).

Depending on the quality measured

Depending on the quality measured

Voltmeter

Ammeter

Energy

meter

Ohm meter

Depending on the different principles used for

their working

Moving

Iron type

Moving

coil type

Dynamometer

type

Induction

type

Depending on how the quantity is measured

Deflecting

type

Integrating

type

Recording

type

Deflecting Torque

The

deflecting torque moves the moving system and the pointer from the zero

position. The deflecting torque can be obtained through magnetic, thermal,

electromagnetic or electro dynamic effects

Controlling torque

The

controlling torque acts in a direction opposite to that of deflecting torque.

When the controlling torque (TC) and the deflecting torque (TD) are numerically

equal the pointer takes a definite position. In the absence of TC the pointer

would deflect to maximum position irrespective of the quantity to be measured.

Moreover TC also helps in bringing the moving system to zero position when the

instrument is disconnected from the circuit. The controlling torque is obtained

through spring control and gravity control

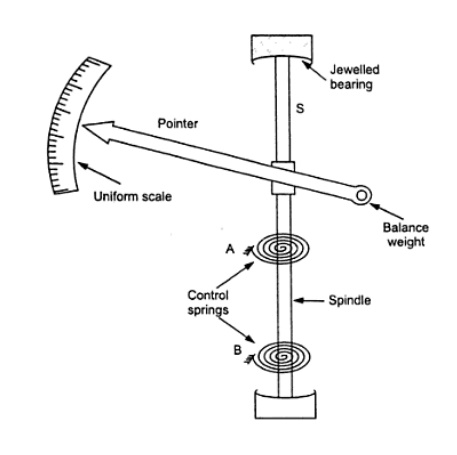

Spring Control:

The

arrangement for spring control consists of two phosphor bronze spiral hair

springs attached to a moving system. The springs are made of materials which

(i). are not affected by fatigue. (ii). Have low temp-coefficient of resistance

(iii). Have low specific resistance (iv). Are non-magnetic

As the

pointer deflects the springs get twisted in the opposite direction. The

combined twist produces the necessary controlling torque which is proportional

to angle of deflection of moving system θ. If we consider a permanent magnet

moving coil meter with spring control system the deflecting torque will be

proportional to the current passing through it and the controlling torque will

be proportional to the angle of deflection

Thus TD

α I

TC

α θ

Since TD

= TC

We have θ

α I

Thus the

spring controlled instruments having uniform scale

Gravity control

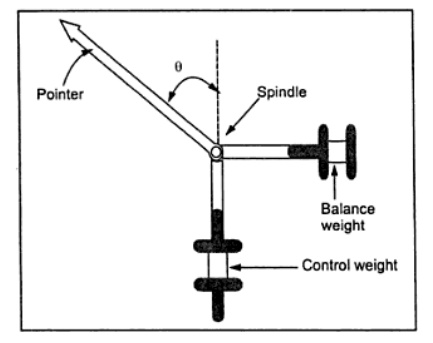

In

gravity controlled instruments, as shown in Fig. 12.2 (a) a small adjustable

weight is attached to the spindle of the moving system such that the deflecting

torque produced by the instrument has to act against the action of gravity.

Thus a controlling torque is obtained. This weight is called the control weight.

Another adjustable weight is also attached is the moving system for zero

adjustment and balancing purpose. This weight is called Balance weight.

When the

control weight is in vertical position as shown in Fig. 12.2 (a), the

controlling torque is zero and hence the pointer must read zero. However, if

the deflecting torque lifts the controlling weight from position A to B as

shown in Fig.12.2 (b) such that the spindle rotates by an angle θ, then due to

gravity a restoring (or controlling) torque is exterted on the moving system.

The

controlling (or restoring) torque, Tc , is given by

Tc = Wl

sin θ = k g sin θ where W is the control weight;

l is the

distance of the control weight from the axis of rotation of the moving system;

and k g is the gravity constant.

Equation

shows the controlling torque can be varied quite simply by adjustment of the

position of the control weight upon the arm which carries it. Again, if the

deflecting torque is directly proportional to the current,

i.e., Td

= kI

We have

at the equilibrium position Td = Tc

kI = k g

sin θ

I = g k

sin θ / k

This

relation shows that current I is proportional to sin θ and not θ. Hence in

gravity controlled instruments the scale is not uniform. It is cramped for the

lower readings, instead of being uniformly divided, for the deflecting torque

assumed to be directly proportional to the quantity being measured.

Advantanges of Gravity Control

1. It is

cheap and not affected by temperature variations.

2. It does

not deteriorate with time.

3. It is

not subject to fatigue.

Disadvantages of Gravity Control

1. Since the

controlling torque is proportional to the sine of the angle of deflection, the

scale is not uniformly divided but cramped at its lower end.

2. It is not

suitable for use in portable instruments (in which spring control is always

preferred).

3. Gravity

control instruments must be used in vertical position so that the control

weight may operate and also must be leveled otherwise they will give zero

error. In view of these reasons, gravity control is not used for indicating

instruments in general and portable instruments in particular.

Damping Torque

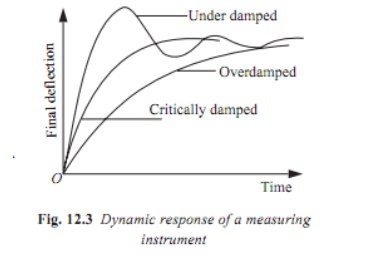

We have

already seen that the moving system of the instrument will tend to move under

the action of the deflecting torque. But on account of the control torque, it

will try to occupy a position of rest when the two torques are equal and

opposite. However, due to inertia of the moving system, the pointer will not

come to rest immediately but oscillate about its final deflected position as

shown in Fig and takes appreciable time to come to steady state. To overcome

this difficulty a damping torque is to be developed by using a damping device

attached to the moving system.

The

damping torque is proportional to the speed of rotation of the moving system,

that is Tv = kv d dt θ

where kv

= damping torque constant

d dt θ =

speed of rotation of the moving system

Depending

upon the degree of damping introduced in the moving system, the instrument may

have any one of the following conditions as depicted in Fig.

1. Under

damped condition: The response is oscillatory

2. Over

damped condition: The response is sluggish and it rises very slowly from its

zero position to final position.

3. Critically

damped condition: When the response settles quickly without any oscillation,

the system is said to be critically damped.

In

practice, the best response is slightly obtained when the damping is below the

critical value i.e., the instrument is slightly under damped.

The

damping torque is produced by the following methods: Air Friction Damping &

Fluid friction damping

Air Friction Damping

In this

type of damping a light vane or vanes having considerable area is attached to

the moving system to develop a frictional force opposing the motion by reason

of the air they displace. Two methods of damping by air friction are depicted

in Fig.

The

arrangement shown in Fig consists of a light aluminum vane which moves in a

quadrant (sector) shaped air chamber. The chamber also carries a cover plate at

the top. The vane is mounted on the spindle of the moving system. The aluminum

vane should not touch the air-chamber walls otherwise a serious error in the

deflection of the instrument will be introduced. Now, with the motion, the vane

displaces air and thereby a damping force is created on the vane that produces

a torque (damping) on the spindle. When the movement is quicker the damping

force is greater; when the spindle is at rest, the damping force is zero.

The

arrangement of Fig. consists of a light aluminum piston which is attached to

the moving system. This piston moves in a fixed chamber which is closed at one

end. Either circular or rectangular chamber may be used. The clearance (or gap)

between the piston and chamber walls should be uniform throughout and as small

as possible. When the piston moves rapidly into the chamber the air in the

closed space is compressed and the pressure of air thus developed opposes the

motion of the piston and thereby the whole moving system. If the piston is

moving out of the chamber, rapidly, the pressure in the closed space falls and

the pressure on the open side of the piston is greater than that on the

opposite side. Motion is thus again opposed. With this damping system care must

be taken to ensure that the arm carrying the piston should not touch the sides

of the chamber during its movement. The friction which otherwise would occur

may introduce a serious error in the deflection.

The air

friction damping is very simple and cheap. But care must be taken to ensure

that the piston is not bent or twisted. This method is used in moving iron and

hot wire instruments.

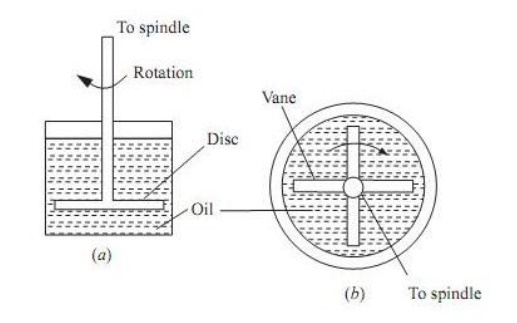

Fluid Friction Damping

This form

is damping is similar to air friction damping. The action is the same as in the

air friction damping. Mineral oil is used in place of air and as the viscosity

of oil is greater, the damping force is also much greater. The vane attached to

the spindle is arranged to move in the damping oil. It is rarely used in

commercial type instruments. The oil used must fulfill the following

requirements. It should not evaporate quickly . It should not have any

corrosive effect on metals. Its viscosity should not change appreciably with

temperature. It should be good insulator.

Advantages of Fluid Friction Damping

1. The oil

used for damping can also be used for insulation purpose in some forms of

instruments which are submerged in oil.

2. The

clearance between the vanes and oil chamber is not as critical as with the air

friction clamping system.

3. This

method is suitable for use with instruments such as electrostatic type where

the movement is suspended rather than pivoted.

4. Due to

the up thrust of oil, the loads on bearings or suspension system is reduced

thereby the reducing the frictional errors.

Disadvantages of Fluid Friction Damping

1. The

instruments with this type of damping must be kept always in a vertical

position.

2. It is

difficult to keep the instrument clean due to leakage of oil.

It is not

suitable for portable instruments. The fluid friction damping can be used for

laboratory type electrostatic instruments.

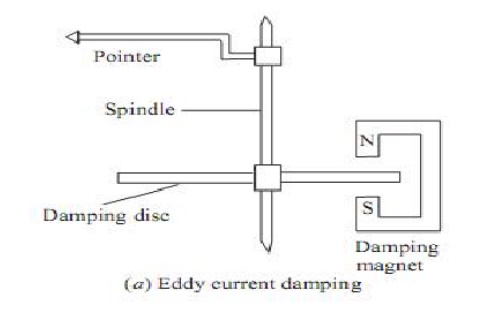

Eddy current damping

Eddy

Current Damping

Eddy

current damping is the most efficient form of damping. The essential components

in this type of damping are a permanent magnet; and a light conducting disc

usually of alumninum. When a sheet of conducting material moves in a magnetic

field so as to cut through lines of force, eddy currents are set up in it and a

force exists between these currents and the magnetic field, which is always in

the direction opposing the motion. \

This

force is proportional to the magnitude of the current, and to the strength of

field. The former is proportional to the velocity of movement of the conductor,

and thus, if the magnetic field is constant, the damping force is proportional

to the velocity of the moving system and is zero when there is no movement of

the system.

Related Topics