Chapter: Embedded and Real Time Systems : Introduction to Embedded Computing

Design Example: Model Train Controller

DESIGN

EXAMPLE: MODEL TRAIN CONTROLLER

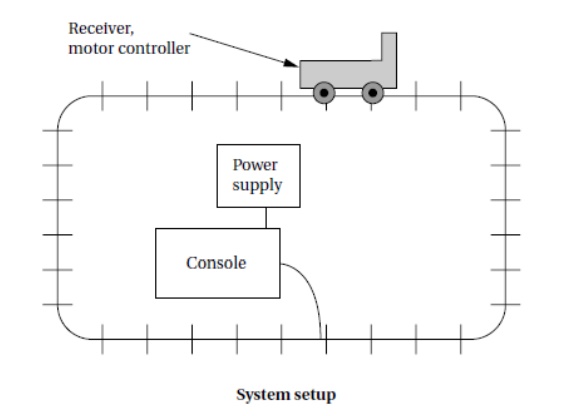

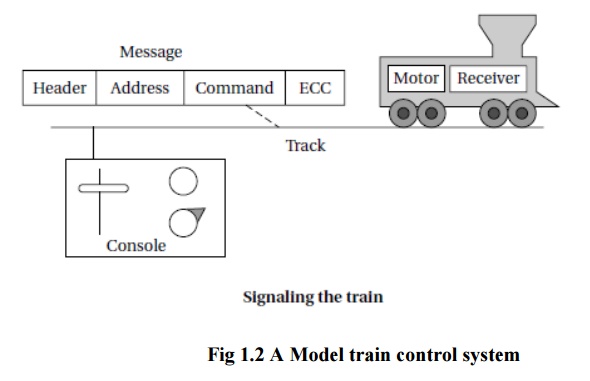

In order

to learn how to use UML to model systems, we will specify a simple system, a

model train controller, which is illustrated in Figure 1.2.The user sends

messages to the train with a control box attached to the tracks.

The

control box may have familiar controls such as a throttle, emergency stop

button, and so on. Since the train receives its electrical power from the two

rails of the track, the control box can send signals to the train over the

tracks by modulating the power supply voltage. As shown in the figure, the

control panel sends packets over the tracks to the receiver on the train.

The train

includes analog electronics to sense the bits being transmitted and a control

system to set the train motor’s speed and direction based on those commands.

Each

packet includes an address so that the console can control several trains on

the same track; the packet also includes an error correction code (ECC) to

guard against transmission errors. This is a one-way communication system the

model train cannot send commands back to the user.

We start

by analyzing the requirements for the train control system.We will base our

system on a real standard developed for model trains.We then develop two

specifications: a simple, high-level specification and then a more detailed

specification.

Requirements

Before we

can create a system specification, we have to understand the requirements.

Here is a

basic set of requirements for the system:

The

console shall be able to control up to eight trains on a single track.

The speed

of each train shall be controllable by a throttle to at least 63 different

levels in each direction (forward and reverse).

There

shall be an inertia control that shall allow the user to adjust the

responsiveness of the train to commanded changes in speed. Higher inertia means

that the train responds more slowly to a change in the throttle, simulating the

inertia of a large train. The inertia control will provide at least eight

different levels.

There

shall be an emergency stop button.

An error

detection scheme will be used to transmit messages.

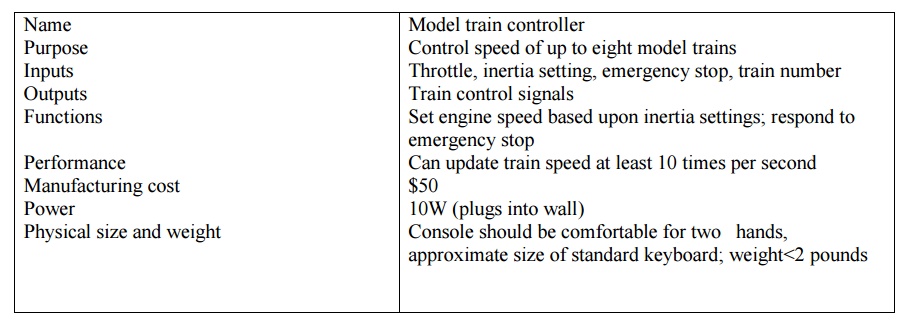

We can

put the requirements into chart format:

We will develop

our system using a widely used standard for model train control. We could

develop our own train control system from scratch, but basing our system upon a

standard has several advantages in this case: It reduces the amount of work we

have to do and it allows us to use a wide variety of existing trains and other

pieces of equipment.

DCC

The Digital Command Control (DCC) was

created by the National Model Railroad Association to support interoperable

digitally-controlled model trains.

Hobbyists

started building homebrew digital control systems in the 1970s and Marklin

developed its own digital control system in the 1980s. DCC was created to

provide a standard that could be built by any manufacturer so that hobbyists

could mix and match components from multiple vendors.

The DCC

standard is given in two documents:

Standard

S-9.1, the DCC Electrical Standard, defines how bits are encoded on the rails

for transmission.

Standard

S-9.2, the DCC Communication Standard, defines the packets that carry

information.

Any

DCC-conforming device must meet these specifications. DCC also provides several

recommended practices. These are not strictly required but they provide some

hints to manufacturers and users as to how to best use DCC.

The DCC

standard does not specify many aspects of a DCC train system. It doesn’t define

the control panel, the type of microprocessor used, the programming language to

be used, or many other aspects of a real model train system.

The

standard concentrates on those aspects of system design that are necessary for

interoperability. Over standardization, or specifying elements that do not

really need to be standardized, only makes the standard less attractive and

harder to implement.

The

Electrical Standard deals with voltages and currents on the track. While the

electrical engineering aspects of this part of the specification are beyond the

scope of the book, we will briefly discuss the data encoding here.

The

standard must be carefully designed because the main function of the track is

to carry power to the locomotives. The signal encoding system should not

interfere with power transmission either to DCC or non-DCC locomotives. A key

requirement is that the data signal should not change the DC value of the

rails.

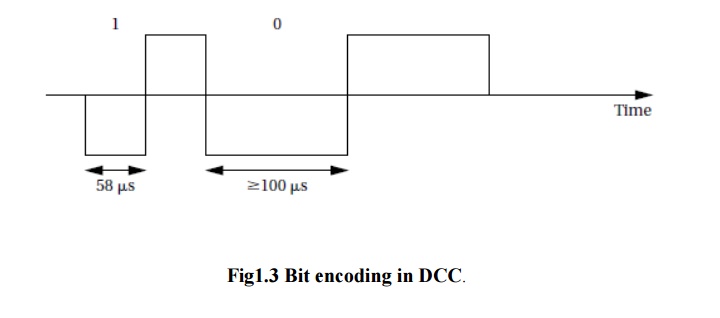

The data

signal swings between two voltages around the power supply voltage. As shown in

Figure 1.3, bits are encoded in the time between transitions, not by voltage

levels. A 0 is at least 100 ms while a 1 is nominally 58ms.

The

durations of the high (above nominal voltage) and low (below nominal voltage)

parts of a bit are equal to keep the DC value constant. The specification also

gives the allowable variations in bit times that a conforming DCC receiver must

be able to tolerate.

The

standard also describes other electrical properties of the system, such as

allowable transition times for signals.

The DCC

Communication Standard describes how bits are combined into packets and the

meaning of some important packets.

Some

packet types are left undefined in the standard but typical uses are given in

Recommended Practices documents. We can write the basic packet format as a

regular expression:

PSA (sD)

+ E ........ ( 1.1)

In this

regular expression:

P is the preamble, which is a sequence

of at least 10 1 bits. The command station should send at least 14 of these 1 bits, some of which may

be corrupted during transmission.

S is the packet start bit. It is a

0 bit.

A is an address data byte that

gives the address of the unit, with the most significant bit of the address transmitted first. An address is eight

bits long. The addresses 00000000, 11111110, and 11111111 are reserved.

s is the data byte start bit,

which, like the packet start bit, is a 0.

D is the data byte, which includes

eight bits. A data byte may contain an address, instruction, data, or error correction information.

E is a packet end bit, which is a 1

bit.

A packet

includes one or more data byte start bit/data byte combinations. Note that the

address data byte is a specific type of data byte.

A baseline

packet is the minimum packet that must be accepted by all DCC

implementations. More complex packets are given in a Recommended Practice

document.

A

baseline packet has three data bytes: an address data byte that gives the

intended receiver of the packet; the instruction data byte provides a basic

instruction; and an error correction data byte is used to detect and correct

transmission errors.

The

instruction data byte carries several pieces of information. Bits 0–3 provide a

4-bit speed value. Bit 4 has an additional speed bit, which is interpreted as

the least significant speed bit. Bit 5 gives direction, with 1 for forward and

0 for reverse. Bits 7–8 are set at 01 to indicate that this instruction

provides speed and direction.

The error

correction data byte is the bitwise exclusive OR of the address and instruction

data bytes.

The

standard says that the command unit should send packets frequently since a

packet may be corrupted. Packets should be separated by at least 5 ms.

Conceptual

Specification

Digital

Command Control specifies some important aspects of the system, particularly

those that allow equipment to interoperate. But DCC deliberately does not

specify everything about a model train control system. We need to round out our

specification with details that complement the DCC spec.

A

conceptual specification allows us to understand the system a little better. We

will use the experience gained by writing the conceptual specification to help

us write a detailed specification to be given to a system architect. This

specification does not correspond to what any commercial DCC controllers do,

but it is simple enough to allow us to cover some basic concepts in system

design.

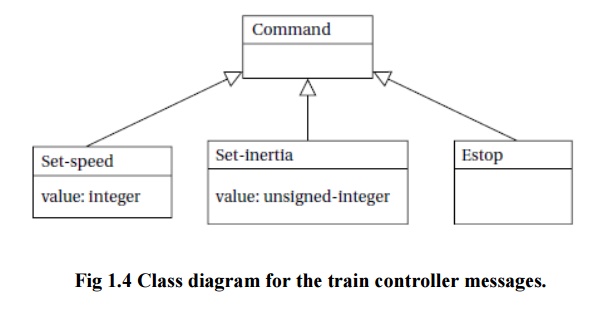

A train

control system turns commands into packets. A command comes

from the command unit while a packet is transmitted over the rails.

Commands

and packets may not be generated in a 1-to-1 ratio. In fact, the DCC standard

says that command units should resend packets in case a packet is dropped

during transmission.

We now

need to model the train control system itself. There are clearly two major

subsystems: the command unit and the train-board component as shown in Figure

1.4. Each of these subsystems has its own internal structure.

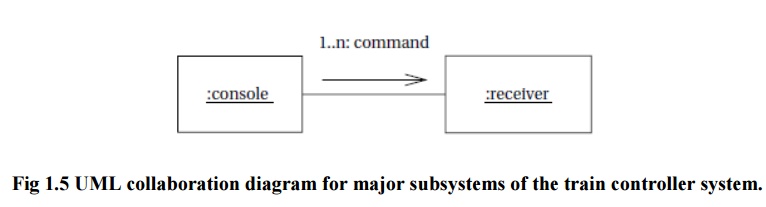

The basic

relationship between them is illustrated in Figure 1.5. This figure shows a UML

collaboration

diagram; we could have used another type of figure, such as a class or

object diagram, but we wanted to emphasize the transmit/receive

relationship between these major subsystems. The command unit and receiver are

each represented by objects; the command unit sends a sequence of packets to

the train’s receiver, as illustrated by the arrow.

The

notation on the arrow provides both the type of message sent and its sequence

in a flow of messages; since the console sends all the messages, we have

numbered the arrow’s messages as

1..n. Those messages are of course

carried over the track.

Since the

track is not a computer component and is purely passive, it does not appear in

the diagram. However, it would be perfectly legitimate to model the track in

the collaboration diagram, and in some situations it may be wise to model such

nontraditional components in the specification diagrams. For example, if we are

worried about what happens when the track breaks, modeling the tracks would

help us identify failure modes and possible recovery mechanisms.

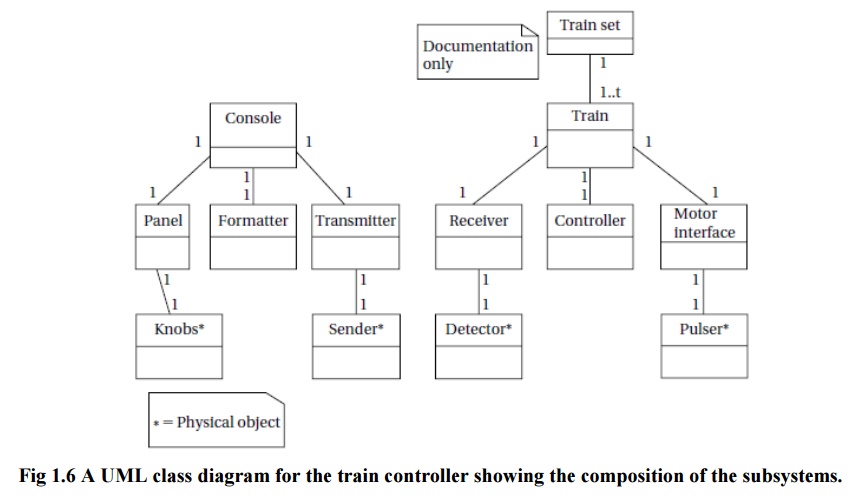

Let’s

break down the command unit and receiver into their major components. The

console needs to perform three functions: read the state of the front panel on

the command unit, format messages, and transmit messages. The train receiver

must also perform three major functions: receive the message, interpret the

message (taking into account the current speed, inertia setting, etc.),and

actually control the motor. In this case, let’s use a class diagram to

represent the design; we could also use an object diagram if we wished. The UML

class diagram is shown in Figure 1.6. It shows the console class using three

classes, one for each of its major components. These classes must define some

behaviors, but for the moment we will concentrate on the basic characteristics

of these classes:

The Console class describes the command

unit’s front panel, which contains the analog knobs and hardware to interface

to the digital parts of the system.

The Formatter class includes behaviors that

know how to read the panel knobs and creates a bit stream for the required

message.

The Transmitter class interfaces to analog

electronics to send the message along the track.

There

will be one instance of the Console

class and one instance of each of the component classes, as shown by the

numeric values at each end of the relationship links. We have also shown some

special classes that represent analog components, ending the name of each with

an asterisk:

Knobs* describes the actual analog

knobs, buttons, and levers on the control panel.

Sender* describes the analog

electronics that send bits along the track.

Likewise,

the Train makes use of three other classes that define its components:

The Receiver class knows how to turn the

analog signals on the track into digital form.

The Controller class includes behaviors that

interpret the commands and figures out how to control the motor.

The Motor interface class defines how to

generate the analog signals required to control the motor. We define two

classes to represent analog components:

Detector* detects analog signals on the

track and converts them into digital form.

Pulser* turns digital commands into the

analog signals required to control the motor speed.

We have

also defined a special class, Train set,

to help us remember that the system can handle multiple trains. The values on

the relationship edge show that one train set can have t trains. We would not actually implement the train set class, but

it does serve as useful documentation of the existence of multiple receivers.

Related Topics