Chapter: Civil : Construction Materials: Lime, Cement, Aggregates, Mortar

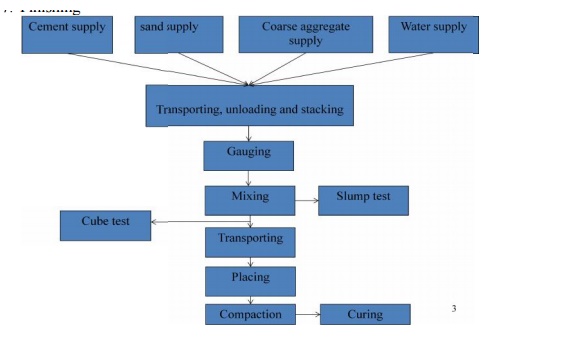

Concrete: Manufacturing Process

Concrete: Manufacturing Process

A good quality concrete is essentially a homogeneous mixture

of cement, coarse and fine aggregates and water which consolidates into a hard

mass due to chemical action between the cement and water. Each of the four

constituents has a specific function. The coarser aggregate acts as a filler.

The fine aggregate fills up the voids between the paste and the coarse

aggregate. The cement in conjunction with water acts as a binder. The mobility

of the mixture is aided by the cement paste, fines and nowadays, increasingly

by the use of admixtures.

Most of the properties of the

hardened concrete depend on the care exercised at every stage of the

manufacture of concrete. A rational proportioning of the ingredients of

concrete is the essence of the mix design. However, it may not guarantee of

having achieved the objective of th e quality concrete work. The aim of quality

control is to ensure the production of con crete of uniform strength from batch

to batch. This requires some rules to be followed in the various stages of

concrete production and are discussed as follows. The stages of concrete

production are:

1. Batching

or measureme nt of materials

2. Mixing

3. Transporting

4. Placing

5. Compacting

6.

Curing

7.

Finishing

Baching of Materials

For good quality co ncrete a

proper and accurate quantity of all th e ingredients should be used. The

aggregates, cement and water should be measured wit h an accuracy of ± 3 per

cent of batch quan tity and the admixtures by 5 per cent of the ba tch quantity.

There are two prevalent meethods of batching materials, the volume batc hing

and the weigh batching. The factors affecting the choice of batching method are

the size of job, required production rate, a nd required standards of batching

performance. For most important works weigh batch ing is recommended.

a) Volume

Batching

b) Weigh

Batching

Mixing

1. Hand

Mixing

2. Machine

Mixing

a) Tilting

Mixers

b) Non-tilting

Mixer

c) Reversing

Drum Mixer

d) Pan-type

or Stirring Mixer

e) Transit

Mixer

Charging the Mixer and Mixing Time

The order of feeding the ingredients into the mixer is as

follows:

About 25 per cent of water

required for mixing is first introduced into the mixer drum to prevent any

sticking of cement on the blades and bottom of the drum. Then the ingredients

are discharged through the skip. In the skip the sequence of loading should be

to add first half the coarse aggregate then half the fine aggregate and over

this total cement and then the balance aggregates. After discharging the

ingredients into the drum the balance water is introduced. The mixing time is

counted from the instant complete water is fed into the mixer.

The speed of the mixers is

generally 15 to 20 rpm. For proper mixing, the number of revolutions per minute

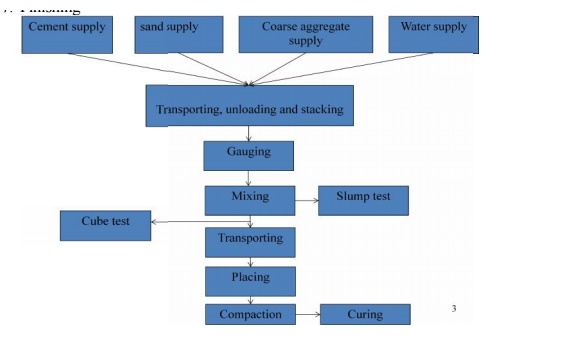

required by the drum are 25 to 30. Time of mixing also depends on capacity of

mixer and is given in Table 10.3.

A poor quality of concrete is

obtained if the mixing time is reduced. On the other hand if the mixing time is

increased it is uneconomical. However, it is found that if the mixing time is

increased to 2 minutes the compressive strength of concrete produced is

enhanced and beyond this time the improvement in compressive strength is

insignificant. A prolonged mixing may cause segregation. Also, due to longer

mixing periods the water may get absorbed by the aggregates or evaporate

resulting in loss of workability and strength.

Transporting

Concrete should be transported to

the place of deposition at the earliest without the loss of homogeneity

obtained at the time of mixing. A maximum of 2 hours from the time of mixing is

permitted if trucks with agitator and 1 hour if trucks without agitators are

used for transporting concrete. Also it should be ensured that segregation does

not take place during transportation and placement. The methods adopted for

transporting concrete depend upon the size and importance of the job, the

distance of the deposition place from the mixing place, and the nature of the

terrain. Some of the methods of transporting concrete are as below:

a. Mortar

Pan

b. Wheel

Barrow

c. Chutes

d. Dumper

e. Bucket

and Ropeway

f. Belt

conveyor

g. Skip and

Hoist

h. Pumping

Placing

To achieve quality concrete it

should be placed with utmost care securing the homogeneity achieved during

mixing and the avoidance of segregation in transporting. Research has shown

that a delayed placing of concrete results in a gain in ultimate compressive

strength provided the concrete can be adequately compacted. For dry mixes in hot

weather delay of half to one hour is allowed whereas for wet mixes in cold

weather it may be several hours. The various situations in which concrete is

placed are discussed below.

Foundations

Concrete foundations for walls

and columns are provided below the ground surface. Before placing the concrete

in the foundation all the loose earth, roots of trees etc., are removed. If the

surface is found dry it is made wet so that earth does not absorb water from

concrete. On the other hand if the foundation bed is wet the water and mud is

removed and cement is sprinkled before placing concrete.

Beams, Columns, and Slabs

Before placing the concrete, the

forms must be examined for correct alignment. They should be adequately rigid

to withstand the weight of concrete and construction loads without undue

deformation. Forms should be light enough to avoid any loss of mortar resulting

in honeycombed concrete. The insides of the forms should be cleaned and oiled

before use to avoid any sticking of concrete with the forms and making their

stripping off difficult.

Concrete should not be dropped

but placed in position to prevent segregation. It should be dropped vertically

from as small height as possible. It should be placed at one point in the

formwork and allowed to flow side ways to take care of honeycombing.

Laitance formation should be

avoided. It can be checked by restricting thickness of layer of concrete by 150-300 mm

for R.C.C work. Laitance, however, if formed must be removed before placing the

next layer of concrete. Several such layers form a lift, provided they follow

one another quickly enough to avoid cold joints. The surface of the previous

lift is kept rough and all the laitance removed before placing the next lift.

The reinforcement should be

checked for tightness and clean surface. The loose rust or scales if any, are

removed by wire brush. Paint, oil or grease if found should be removed. The

minimum cover for reinforcement should be checked before concreting.

Mass Concreting

When the concrete is to be laid

in mass as for raft foundation, dam, bridge, pier etc., concrete is placed in

layers of 350-450 mm thickness. Several such layers placed

in quick succession form a lift. Before placing the concrete in the next lift,

the surface of the previous lift is cleaned thoroughly with water jets and

scrubbing by wire brush. In case of dams, sand blasting is done.

The laitance and loose materials

are removed and cement slurry is applied. When the concrete is subjected to

lateral thrust, bond bars or bond stones are provided to form a

key between different layers.

Concreting Highways and Runways

Concrete is laid in bays for

highway, runway, or floor slabs. First the ground on which concrete is to be

laid is prepared and all the loose materials and grass etc., are removed. The

earth is wetted and compacted. The subgrades over which concrete is to be laid

should be properly compacted and damped to avoid any loss of moisture from

concrete. Concrete is then laid in alternate bays. This allows the concrete to

undergo sufficient shrinkage and cracks do not develop afterwards. Concrete is

not placed in heap at one place and then dragged, instead it is placed in

uniform thickness.

Concreting Underwater

Concrete may be placed underwater

with the help of bottom dump buckets. The concrete is taken through the water

in water- tight bucket. On reaching the place of deposition the bottom of the

bucket is made to open and the concrete is dumped. In this process certain

amount of cement is washed away causing a reduction in strength of concrete.

Another way of concreting underwater is by filling cement bag with dry or

semi-dry mix of cement and aggregates and lowering them to the place of

deposition. The draw back of this method is that the concrete will be full of

voids interspersed with purticible gunny bags.

The best method of placing

concrete underwater is by the use of termie pipe. The concrete is poured

into it through funnel. The bottom end of the pipe is closed with a thick

ploythene sheet, with the bottom end of the pipe at the place of deposition.

The concrete (slump 150-200 mm) is poured into funnel

till the whole pipe is filled with concrete. The pipe is slightly lifted and

given a jerk, the polythene sheet cover falls and concrete discharged. It

should be ensured that the end of pipe remains inside the concrete so that

water does not enter the pipe. The pipe is again filled with concrete through

funnel and the process repeated till the concrete level comes above the water

level. No compaction is required for underwater concrete as it gets compacted

by the hydrostatic pressure of water. Concrete can also be placed underwater

with the help of pipes and pumps.

Compaction

After concrete is placed at the

desired location, the next step in the process of concrete production is its

compaction. Compaction consolidates fresh concrete within the moulds or

frameworks and around embedded parts and reinforcement steel. Considerable

quantity of air is entrapped in concrete during its production and there is

possible partial segregation also. Both of these adversely affect the quality

of concrete. Compaction of the concrete is the process to get rid of the

entrapped air and voids, elimination of segregation occurred and to form a

homogeneous dense mass. It has been found that 5 per cent voids in hardened

concrete reduce the strength by over 30 per cent and 10 per cent voids reduce

the strength by over 50 per cent. Therefore, the density and consequently the

strength and durability of concrete largely depend upon the degree of

compaction. For maximum strength driest possible concrete should be compacted

100 per cent.

The voids increase the

permeability of concrete. Loss of impermeability creates easy passage of

moisture, oxygen, chlorides, and other aggressive chemicals into the concrete.

This causes rusting of steel and spalling (disintegration) of concrete i.e.,

loss of durability. Easy entry of sulphates from the environment causes

expansive reaction with the tricalcium aluminate (C3A) present in

cement. This causes disintegration of concrete and loss of durability. Entry of

carbon dioxide causes carbonation of concrete i.e., loss of alkalinity of

concrete or loss of the protective power that concrete gives to the

reinforcement or other steel embedded in it. Once the carbonation depth exceeds

the thickness of concrete cover to the embedded steel, steel becomes vulnerable

to the attack of moisture. This expedites rusting of steel as the protective

concrete cover remains no longer alkaline in nature.

Voids also reduce the contact

between embedded steel and concrete. This results in loss of bond strength of

reinforced concrete member and thus the member loses strength. Voids such as

honeycombs and blowholes on the exposed surface produce visual blemish.

Concrete surface is not good to look with all such blemishes. Concrete with

smooth and perfect, surface finish not only looks good but is also stronger and

more durable.

Compaction is achieved by

imparting external work over the concrete to overcome the internal friction

between the particles forming the concrete, between concrete and reinforcement

and between concrete and forms and by reducing the air voids to a minimum. The

compaction of concrete can be achieved by the following methods.

1. Hand

Compaction

2. Compaction

by Vibration

a. Needle

Vibrator:

b. Formwork

Vibrator

3. Compaction

by Spinning

4. Compaction

by Jolting

5. Compaction

by Rolling

Curing

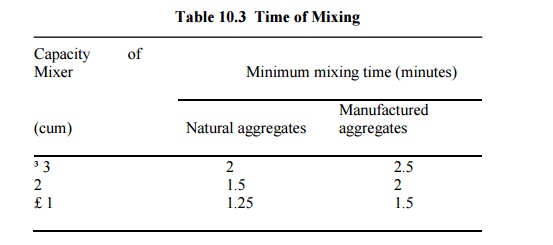

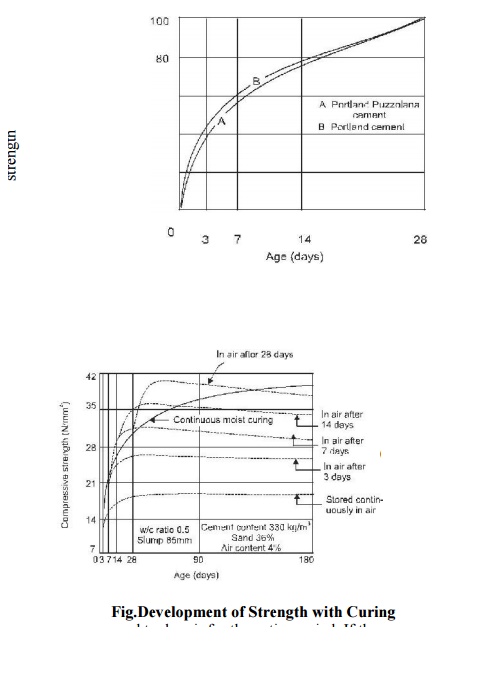

Cement gains strength and

hardness because of the chemical action between cement and water. This chemical

reaction requires moisture, favourable temperature and time referred to as the

curing period. The variation of compressive strength with curing period is

shown in Fig. 10.11 (a, b). Curing of freshly placed concrete is very important

for optimum strength and durability. The major part of the strength in the

initial period is contributed by the clinker compound C3S and partly

by C2S, and is completed in about three weeks. The later strength

contributed by C2S is

gradual and takes long time. As such sufficient water should be made available

to concrete to allow it to gain full strength. The process of keeping concrete

damp for this purpose is known as curing. The object is to prevent the loss

of moisture from concrete due to

evaporation or any other reason,

supply additional moisture or heat and moisture to accelerate the gain of

strength. Curing must be done for at least three weeks and in no case for less

than ten days.

Approximately 14 litres of water

is required to hydrate each bag of cement. Soon after the concrete is placed,

the increase in strength is very rapid (3 to 7 days) and continues slowly

thereafter for an indefinite period. Concrete moist cured for 7 days is about

50 per cent stronger than that which is exposed to dry air for the entire

period. If the concrete is kept damp for one month, the strength is about

double than that of concrete exposed only to dry air.

Methods of Curing

Concrete may be kept moist by a

number of ways. The methods consist in either supplying additional moisture to

concrete during early hardening period by ponding, spraying, sprinkling, etc.

or by preventing loss of moisture from concrete by sealing the surface of

concrete by membrane formed by curing compounds. Following are some of the

prevelent methods of curing.

1. Water

Curing

2. Steam

Curing

3. Curing by

Infra Red Radiation:

4. Electrical

Curing

5. Chemical

Curing:

Finishing

Concrete is basically used

because of its high compressive strength. However, the finish of the ultimate

product is not that pleasant. In past couple of decades efforts have been made

to develop surface finishes to give a better appearance to concrete surfaces

and are as follows.

1. Formwork

Finishes

2. Surface

Treatments

3. Applied

Finishes

Related Topics