Chapter: Aquaculture Engineering : Tanks, Basins and Other Closed Production Units

Water outlet or drain - Aquaculture Engineering

Water outlet or drain

The tank outlet or drain normally

has two functions: 1, to remove the waste from the tank as quickly as possible,

before the leakage of nutrient starts; 2, to maintain the correct water level

inside the tank. Correct design of the outlet is also important for the water

exchange rate and to ensure effective self-cleaning. Incorrect specification of

the outlet system or the outlet pipe may result in settling of uneaten feed

particles and faeces, and the outlet system will function as a settling basin.

This situation can be rectified by shock draining the tank, by removing the

device that controls the tank water level. Shock draining will increase the

water velocity through the outlet above normal and eventually settled solids

will be dragged out. If there are large number of particles coming out, there

may be places in the outlet pipe system where settling of solids occurs if the

design of the outlet system is sub-optimal. It should not be necessary to shock

drain a well-designed outlet system to remove particles that have settled in the

outlet. The outlet pipe should be designed for water velocities above 0.3 m/s

to ensure no settling of solids. Velocities above 1.5 m/s in the outlet will

result in rough treat- ment of the particles which may break up. This makes

later filtration of the outlet water more difficult.

It is important to treat the

outlet water as gently as possible to avoid increased particle breakage. Elbows

and other pipe parts that create additional turbulence should therefore be

avoided. It is important to use long bends and small bend angles in the piping.

It is also important to understand that the inlet and outlet of a tank are

designed for a given flow rate, but with some latitude outside which the inlet

and outlet will not function optimally because the velocity is either too low

or too high.

The head loss in the outlet

system can be seen by comparing the water level inside the tank with the top

level of the water in the outlet system. A large difference means a high head

loss.

Example

The supply of water to a fish tank with a farming volume of 6 m3

should be between 60 and 200 l/min to ensure

sufficient self-cleaning. Find a suitable diameter for the outlet pipe.

Choose a velocity of 0.5 m/s and

calculate for the smallest amount of water.

The next task is to calculate the water velocity in the pipe

with the largest amount of water when the radius of the pipe is 2.5 cm.

V = Q/A

Q =200 l/min=0.0033 m3/s

V =1.67m/s

A larger dimension for the outlet pipe is recommended because

this velocity is rather high. This also shows that the outlet system is not

designed optimally if there is too large a variation in the water flow.

When designing the outlet system,

it is important that the outlet creates a drag on the water in the tank.

Particles lying close to the outlet will be forced against the outlet by the

reduced pressure there.

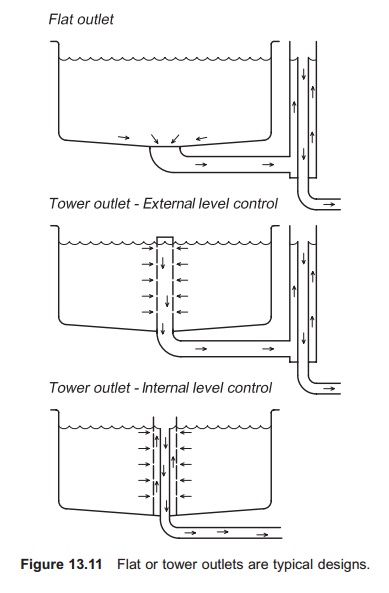

The design of the outlet can be

either of the flat or tower type (Fig. 13.11). The flat outlet contains a

horizontal screen inside the fish tank, adapted to the fish size. This normally

covers an outlet pot. From the outlet pot the outlet pipe goes to a vertical

standing pipe where the water level inside the tank is controlled. It is

important to increase the speed through the holes in the outlet screen to avoid

fouling and blockage. Velocities above 0.3–0.4 m/s are recommended. The outlet

screen is a perforated sheet of stainless steel, aluminium or plastic. Good

results have been achieved by using oblong slots instead of holes in the outlet

screen. Slots do not clog as quickly and are easier to clean. The holes or

slots are recommended to be as large as possible, but of course not so large

that fish escape. It may also be possible to run the tank without any outlet

screen, because the fish prefer not to go down in the outlet pipe. However,

this is species dependent, and some species that have a crowding behaviour,

such as eel, will go down. For salmonids, the author’s experience is that it is

possible to run without any outlet screen. If this is done it is necessary to

install a trap in the outlet system to collect the dead fish (see Section

13.11).

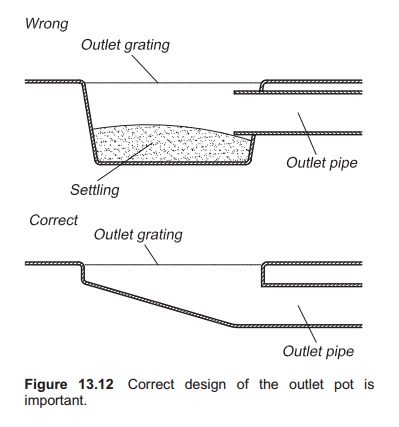

The outlet pot, if used in the

tank, has been shown to be a critical part of the construction (Fig. 13.12).

Settling of solids is very common here. It is therefore important not to reduce

the water velocity in this pot too much, both to prevent set-tling of particles

and also to reduce the amount of fouling. Good results are obtained by using an

eccentric outlet from the pot; here the outlet pipe from the pot is not in the

centre but to one side, and a swirl is therefore created inside the pot.

Another possibility is to avoid the use of the outlet pot

totally by having the outlet pipe

directly into the tank bottom. This requires the use of another type of outlet

screen inside the tank (not a horizontal one) to ensure enough hole or slot

area. Outlet screens may, for instance, be shaped like a cone, pyramid or a

small tower, not reaching the water surface.

There are two types of tower

outlet, with either internal or external regulation of the water level. In both

cases there will be a tower inside the tank going from the bottom to the water

surface, consisting of a screen with holes or slots that prevent the fish

leaving the tank. The disadvantage of this outlet is that the presence of the

tower in the middle of the tank may make it difficult to handle the fish in the

tank. With regard to self-cleaning, no differences have been observed between

flat and tower outlet systems.

Instead of taking the outlet from

the bottom of the tank, a siphon can be used. Here the outlet from the tank

goes over the top edge of the tank; however, this will require a fixed water

level. The advantage with the system is that it is not necessary to have any

pipes going out of the bottom of the tank, which is therefore only a basin.

This reduces the cost and increases the second hand value. The disadvantage is

that it is not possible to reduce the water level because it is fixed; a pump

must be used to drain the tank completely.

Both flat and tower outlets,

include a level control to keep the water inside the tank at a given height.

Level controls can be adjustable or fixed. Adjustable level controls can be

incremental or continuous. Fixed level controls have no possibili-ties for

adjustment and therefore there must be a bypass for complete drainage of the

tanks. For large volume tanks (>100 m3) adjustable

level controls are quite expensive and seldom used. Usually fixed or perhaps

incremental controls are installed. A continuous level control may be built by

having a sliding pipe inside another pipe. The same principle may be used for a

stepwise control, but here the level is controlled by addition and removal of

pipe parts.

Related Topics