Chapter: Aquaculture Engineering : Tanks, Basins and Other Closed Production Units

Flow pattern and self-cleaning - Aquaculture Engineering

Flow pattern and self-cleaning

A flow pattern will be created

inside a production unit having a water inlet and outlet. It is important that

this flow pattern encompasses the entire unit so that all the fish can come

into contact with flowing water. The flow pattern depends on the design of the

production unit.

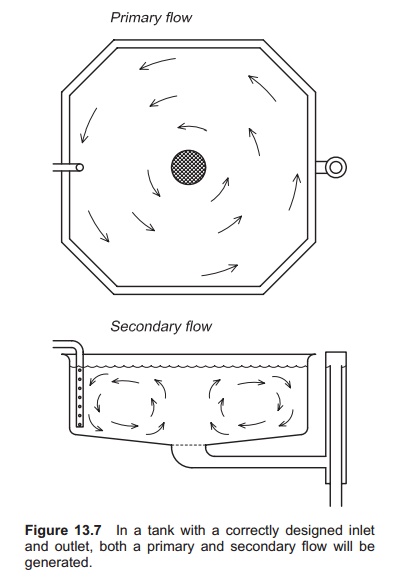

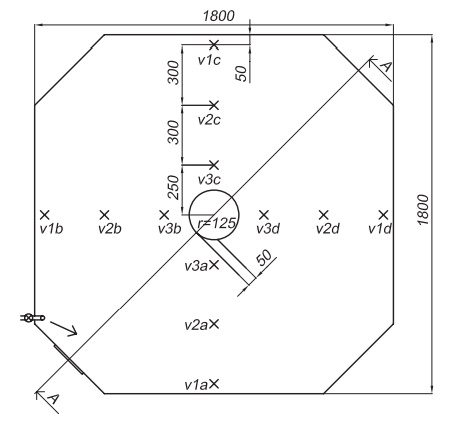

In a tank with a circulating

water flow and correctly designed inlet and outlet, two flow patterns will occur:

the primary flow and the secondary flow (Fig. 13.7). The primary flow causes

even distribution

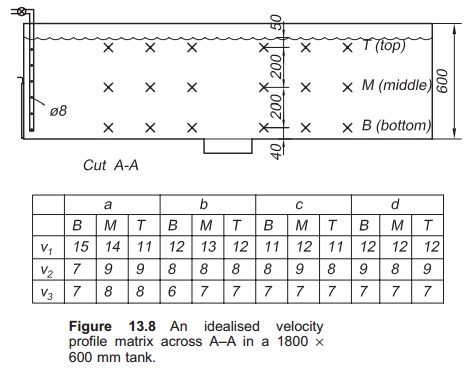

In well-designed tanks with

correctly designed and constructed inlet and outlet, the incoming water may

therefore be used to clean the tank walls and bottom. This process is known as

hydraulic self-cleaning. To achieve self-cleaning in a tank, a certain amount

of water has to be added; the amount depends on the tank construction. The

water velocity at the bottom of the tank must be so high that the settled

solids are removed. To ensure transport of settled solids in circular tanks,

the recommended bottom velocity to ensure self-cleaning is above 6–8 cm/s.7This

will also remove algal growth from the tank sides. Inside the tank there will

be a velocity profile equal to that in a channel, where the lowest velocity

occurs near the bottom due to friction (Fig. 13.8). Bottom water velocities of

between 6 and 8 cm/s normally represent a water velocity in the free water mass

of between 12 and 15 cm/s.7 Practical experience has also shown that

high fish density promotes self-cleaning of the bottom. A lower velocity could

therefore be accepted when the fish density is increased because the movement

of the fish results in resus-pension of settled solids, so the secondary flow

pattern could more easily transport the particles to the drain.

In a correctly designed flow

through tank with inlet and outlet, and a circular flow pattern, the water

retention time should be between 30 and 100 min for satisfactory self-cleaning. This

means a flow through of between 10 and 33 l/m3 farming volume. A

retention time of less than 30 min may create a vortex around the centre drain.

The peripheral velocity in the tank may also be so high that the fish will have

problems staying there. When using low retention times, a specially designed

inlet and outlet are necessary. With retention times above 100 min the

self-cleaning effect is decreased and additional cleaning is necessary.

To attain hydraulic

self-cleaning, a high volume of water is needed to create a high water velocity

inside the tank. Even if the water velocity has yielded improved growth

results, there is a maximum velocity that not must be exceeded.14

This will vary according to species and growth stage. Examples here are fry of

marine or freshwater species, where only very low velocity is tolerated; to

maintain satisfactory water quality for these

species is therefore a challenge. Settled particles and fouling on the tank

bottom and sides will create a sub-optimal environment, and be a good substrate

for unwanted bacterial growth. Regular removing of fouling is therefore

absolutely essential. If this is done manually, it is labour intensive, and

therefore commercially available automatic systems are preferred. Rotating

brushes on the bottom of the tank, powered either by electric motors or by the

pressure of the incoming water are one solution. Other solutions include a

small turtle-like unit moving around on the tank bottom or installing a washing

arm half the pipe diameter in length. Addition of chemicals that remove the

fouling, such as oxidizing agents, has also been tried by the author and

colleagues.

Related Topics