Chapter: Aquaculture Engineering : Tanks, Basins and Other Closed Production Units

Ideal or non-ideal mixing and water exchange

Ideal or non-ideal mixing and water exchange

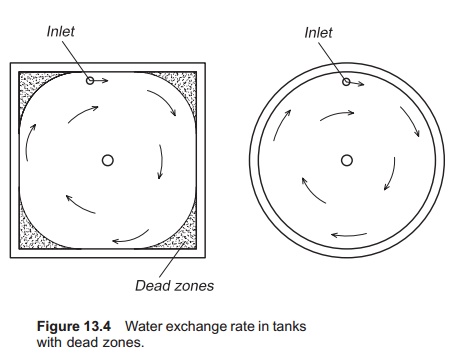

The aim in

designing a closed production unit including the inlet and outlet, is to

achieve the most effective mixing as possible of the new incoming water to the

old water together with a good exchange of water in the entire farming volume.

No new water must go directly to the outlet, by what could be called a short

cut; neither must there be areas or zones in the unit were there is small or no

exchange of water, so called ‘dead zones’ (Fig. 13.4). Since water exchange

does not occur in the completely dead zones, no new water or oxygen is

sup-plied, so the fish will prefer not to stay there and the effective farming

volume will be reduced below the real tank volume. If there are short cuts,

part of the inlet water will go directly to the outlet without having been

properly utilized by the fish; this results is non-ideal mixing. Short cuts

will also give zones in the unit where the water flows much more slowly and

than elsewhere water exchange will therefore not be satisfactory.

A picture of

the velocity gradients within the production unit can be found by using a

specially designed small propeller – a velocity meter – to measure the flow

rate at different points in the tank both horizontally and vertically (different

depths). Eventually, dead zones and zones where the water flow is too fast will

also be identified.

A number of

factors, including design of the tank, the inlet and the outlet, will affect

water exchange. Before starting to use a new tank design or inlet or outlet

system, it is advantageous to test the flow pattern in the tank and find the

velocity gradients.

Related Topics