Chapter: Aquaculture Engineering : Tanks, Basins and Other Closed Production Units

Types of closed production units - Aquaculture Engineering

Types of closed production units

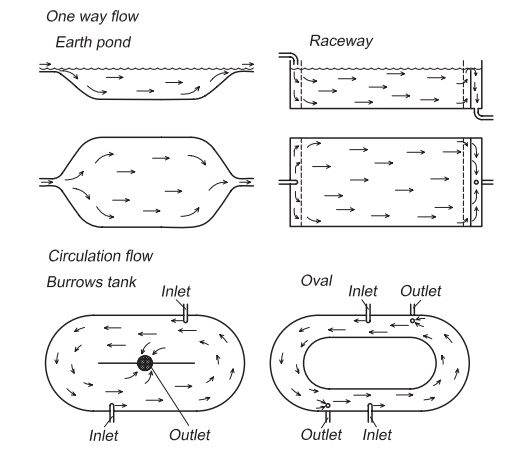

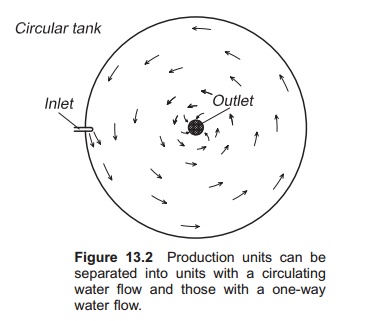

The flow

pattern of the water in the unit can be used to classify closed production

units (Fig. 13.2):

· Production

units with a circulating water flow

· Production

units with a one-way water flow.

Production

units with a circulating water flow may again be separated into tanks with a

circular flow pattern (as is most common), or oval tanks that have an oval flow

pattern, of which there are several types; for example,

Foster Lucas tanks and Burrow tanks, as well as different ovals and pipe

connections. Among the traditional tanks with circular water flow, one type may

be defined as a farming silo. This is a circular tank of greater height than

diameter, i.e. a tower. It is normally difficult to achieve satisfactory water

exchange and self-cleaning in silos.

Earth ponds

belong to the group of production units with one-way water flow and represent

the oldest type of closed production units used for fish production. They are

mainly used for extensive fish farming; i.e. there is a low production per unit

farming volume.

According to

the requirements for closed production units, the main interest in using ponds

is the low initial cost per unit farming volume. In addition, normally a

natural ecosystem that can be utilized is created inside the ponds. In some

countries such as Norway, no new permits for earth ponds are given unless they

are dried once a year. This is because it is quite difficult to control disease

as pathogenic micro-organisms may survive in the earth. If the ponds are dried

during the winter season these micro-organisms will probably be killed. A layer

of lime which increases the pH may also be used as a disinfectant. If the ponds

are covered with a plastic tarpaulin (polyvinyl chloride (PVC) or polyethylene

(PE)) the problems are avoided because such ponds may be cleaned inside, but

this is not a normal pond design, and such installations are more like a

traditional tank with no ecosystem inside.

A further

development of the earth pond is the raceway, which also uses the one-way flow

pattern. This is a fixed construction often of concrete, built as a long

rectangle. The water is supplied at one end and the outlet is located at the

opposite end. Race-ways are quite commonly used for various species throughout

the world. However, raceways require quite large amounts of water to have

effective hydraulic self-cleaning of their total volume, and even then

it is very difficult to get good cleaning results. Normally, some kind of

mechanical equip-ment is necessary for additional cleaning of the raceway. It

is therefore important to create a good flow pattern inside the unit, with a

correctly designed flow inlet and outlet, to ensure uniform water flow through

the entire cross-sectional area and length of the raceway to reduce the

require-ment for manual cleaning. During the past few years, a specially

designed raceway with a very low water level (10–50 cm) has been developed. The unit is

specially designed for fish species that need a bottom to lie on and do not

utilize the entire water column, for example halibut and wolf fish. The unit is

constructed so that it can be installed in tiers, one above the other.

Closed floating

cages are also a type of closed production unit. In this case, both circulating

water flow and one-way flow systems have been tried in different variants that

have been constructed using different materials. In one variant the traditional

net bag in a sea cage has been substituted by plastic sheeting. Water is pumped

into the bag tangential to the edge and the outlet is placed in the centre of

the unit. This creates water circulation inside the bag (see, for example, Ref.

6). The advantage of this type of unit is that it lies on the water surface and

there is only a small head to over-come to pump the water into the cage,

compared with, for instance, closed production units placed on shore and where

seawater is normally pumped several metres.

As shown, a

closed productions unit can be built in several ways and can have different

water flow patterns. The design of the production units, however, depends on

the type of aquatic organism to be grown and its requirements regarding water

distribution and bottom conditions.

Related Topics