Chapter: Special Electrical Machines : Permanent Magnet Synchronous Motor

Vector Control of BLPM SNW Motor

VECTOR CONTROL OF BLPM SNW MOTOR

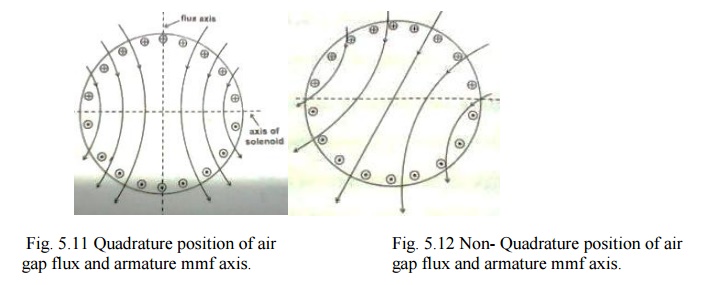

Electromagnetic

torque in any electrical machine is developed due to the interaction of current

carrying armature conductors with the air gap flux. Consider a two machine

whose armature conductor currents and air gap flux are as shown in fig. 5.12.

Here the flux is in quadrature with the armature mmf axis.

Each and

every armature conductor experiences a force which contributes the torque. The

torque contributed by various armature conductors have the same direction even

through their magnitude may vary. It is observed that the steady state and

dynamic (behaviors) performance of a most of such an arrangement are better.

Consider

a second case wherein the armature conductor current distribution and air gap

flux distribution are as shown in fig. 6.26. In this case the angle between the

axis of the air gap flux and the armature mmf axis is different from 90° elec.

In this

case also each and every armature conductor experiences a force and contributes

to the torque. But in this case the direction of the torque experienced by the

conductors is not the same. Since conduction develops torque in one direction

while the others develop in the opposite direction. As a result, the resultant

torque gets reduced; consequently it is observed that both the steady state and

dynamic performance of such a motor is poorer.

For a

BLPM motor to have better steady state and dynamic performance, it is essential

that the armature mmf axis and the axis of PM are to be in quadrature for all

operating condition.

1. Principle of vector control

BLPM SNW

motor is usually employed for variable speed applications. For this we keep V/f

constant and vary V and f to get the desired speed and torque.

From the

theory of BLPM SNW motor it is known that as the speed is varied from a very

low value upto the corner frequency, the desired operating point of current is

such that Id =0 and I is along the q-axis. Such a condition can be

achieved by suitably controlling the voltage by PWM technique after adjusting

the frequency to a desired value.

When the

frequency is more than the corner frequency it is not possible to make Id

=0, due to the voltage constraints. In such a case a better operating point for

current is obtained with minimum Id value after satisfying the

voltage constraints. Controlling BLPM SNW motor taking into consideration the

above mentioned aspects is known as ―vector Control‖ of BLPM SNW motor.

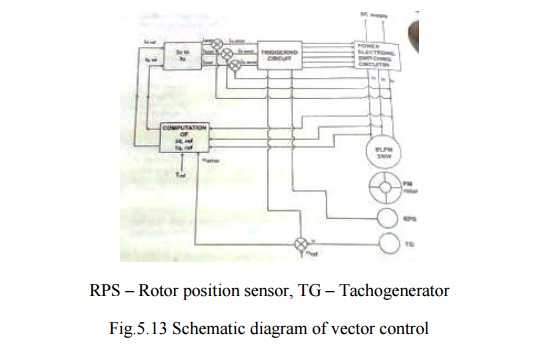

2. Schematic Diagram of Vector

Control

The

schematic block diagram of vector control is as shown in figure 5.13Knowing the

value of the desired torque and speed and also the parameters and the voltage

to which the motor is subjected to, it is possible to complete the values of id

.ref and iq .ref for the desired dynamic and steady state

performance.

The

reference values of id and iq are transformed into

reference values of currents namely ia ref, ib ref and ic

ref. These currents are compared with the actual currents and the error values

actuate the triggering circuitry which is also influenced by the rotor position

sensor and speed. Thus the vector control of BLPM SNW motor is achieved.

Related Topics