Chapter: Computer Graphics and Multimedia

Three Dimensional Object Representations

Three Dimensional Object

Representations

Representation

schemes for solid objects are divided into two categories as follows: 1.

Boundary Representation ( B-reps)

It

describes a three dimensional object as a set of surfaces that separate the

object interior from the environment. Examples are polygon facets and spline

patches.

2. Space

Partitioning representation

It

describes the interior properties, by partitioning the spatial region

containing an object into a set of small, nonoverlapping, contiguous

solids(usually cubes). Eg: Octree Representation.

Polygon Surfaces

Polygon

surfaces are boundary representations for a 3D graphics object is a set of

polygons that enclose the object interior.

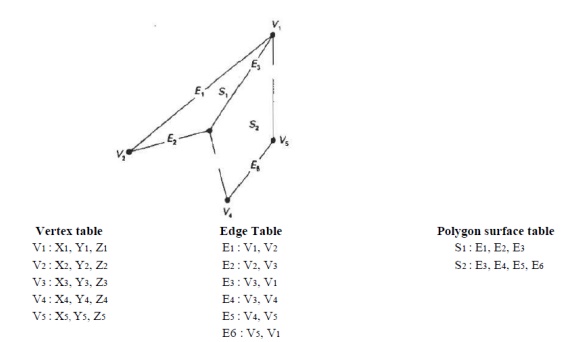

Polygon Tables

The

polygon surface is specified with a set of vertex coordinates and associated

attribute parameters.

For each

polygon input, the data are placed into tables that are to be used in the

subsequent processing.

Polygon

data tables can be organized into two groups: Geometric tables and attribute tables.

Geometric Tables Contain vertex coordinates and

parameters to identify the spatial orientation of the polygon surfaces.

Attribute tables Contain attribute information for

an object such as parameters specifying the

degree of transparency of the object and its surface reflectivity and

texture characteristics. A convenient organization for storing geometric data

is to create three lists:

1. The

Vertex Table

Coordinate

values for each vertex in the object are stored in this table. 2. The Edge

Table

It

contains pointers back into the vertex table to identify the vertices for each

polygon edge. 3. The Polygon Table

It contains pointers back into the edge table to identify the edges for each polygon. This is shown in fig

Listing

the geometric data in three tables provides a convenient reference to the

individual components (vertices, edges and polygons) of each object.

The

object can be displayed efficiently by using data from the edge table to draw

the component lines.

Extra

information can be added to the data tables for faster information extraction.

For instance, edge table can be expanded to include forward points into the

polygon table so that common edges between polygons can be identified more

rapidly.

E1 : V1,

V2, S1

E2 : V2,

V3, S1

E3 : V3,

V1, S1, S2

E4 : V3,

V4, S2

E5 : V4,

V5, S2

E6 : V5,

V1, S2

is useful

for the rendering procedure that must vary surface shading smoothly across the

edges from one polygon to the next. Similarly, the vertex table can be expanded

so that vertices are cross-referenced to corresponding edges.

Additional

geometric information that is stored in the data tables includes the slope for

each edge and the coordinate extends for each polygon. As vertices are input,

we can calculate edge slopes and we can scan the coordinate values to identify

the minimum and maximum x, y and z values for individual polygons.

The more

information included in the data tables will be easier to check for errors.

Some of the tests that could be performed by a graphics package are:

1. That

every vertex is listed as an endpoint for at least two edges.

2. That

every edge is part of at least one polygon.

3. That

every polygon is closed.

4. That each

polygon has at least one shared edge.

5. That if

the edge table contains pointers to polygons, every edge referenced by a

polygon pointer has a reciprocal pointer back to the polygon.

Plane Equations:

To

produce a display of a 3D object, we must process the input data representation

for the object through several procedures such as,

- Transformation

of the modeling and world coordinate descriptions to viewing coordinates.

- Then to

device coordinates:

- Identification

of visible surfaces

- The

application of surface-rendering procedures.

For these

processes, we need information about the spatial orientation of the individual

surface components of the object. This information is obtained from the vertex

coordinate value and the equations that describe the polygon planes.

The

equation for a plane surface is Ax + By+ Cz + D = 0 ----(1)

Where (x,

y, z) is any point on the plane, and the coefficients A,B,C and D are constants

describing the spatial properties of the plane.

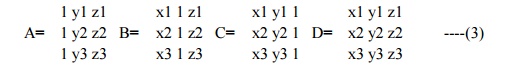

We can

obtain the values of A, B,C and D by solving a set of three plane equations

using the coordinate values for three non collinear points in the plane.

For that,

we can select three successive polygon vertices (x1, y1, z1), (x2, y2, z2) and

(x3, y3, z3) and solve the following set of simultaneous linear plane equations

for the ratios A/D, B/D and C/D.

(A/D)xk +

(B/D)yk + (c/D)zk = -1, k=1,2,3 -----(2)

The

solution for this set of equations can be obtained in determinant form, using

Cramer’s rule as

Expanding the determinants , we can write the calculations for the plane coefficients in the form:

A = y1 (z2 –z3 ) + y2(z3 –z1 ) + y3 (z1 –z2 )

B = z1

(x2 -x3 ) + z2 (x3 -x1 ) + z3 (x1 -x2 )

C = x1

(y2 –y3 ) + x2 (y3 –y1 ) + x3 (y1 -y2 )

D = -x1

(y2 z3 -y3 z2 ) - x2 (y3 z1 -y1 z3 ) - x3 (y1 z2 -y2 z1) ------(4)

As vertex

values and other information are entered into the polygon data structure,

values for A, B, C and D are computed for each polygon and stored with the

other polygon data.

Plane

equations are used also to identify the position of spatial points relative to

the plane surfaces of an object. For any point (x, y, z) hot on a plane with

parameters A,B,C,D, we have

Ax + By +

Cz + D ≠ 0

We can

identify the point as either inside or outside the plane surface according o

the sigh (negative or positive) of Ax + By + Cz + D:

If Ax +

By + Cz + D < 0, the point (x, y, z) is inside the surface. If Ax + By + Cz

+ D > 0, the point (x, y, z) is outside the surface.

These

inequality tests are valid in a right handed Cartesian system, provided the

plane parmeters A,B,C and D were calculated using vertices selected in a

counter clockwise order when viewing the surface in an outside-to-inside

direction.

Polygon Meshes

A single

plane surface can be specified with a function such as fillArea. But when object surfaces are to be tiled, it is more

convenient to specify the surface facets with a mesh function. One type of

polygon mesh is the triangle strip.A

triangle strip formed with 11 triangles connecting 13 vertices.

This

function produces n-2 connected triangles given the coordinates for n vertices.

Another

similar function in the quadrilateral

mesh, which generates a mesh of (n-1) by (m-1) quadrilaterals, given the

coordinates for an n by m array of vertices. Figure shows 20 vertices forming a

mesh of 12 quadrilaterals.

Curved Lines and Surfaces Displays

of three dimensional curved lines and surface can be generated from an input set of mathematical functions defining the

objects or from a set of user specified data points. When functions are

specified, a package can project the defining equations for a curve to the

display plane and plot pixel positions along the path of the projected

function. For surfaces, a functional description in decorated to produce a

polygon-mesh approximation to the surface.

Spline Representations A Spline

is a flexible strip used to produce a smooth curve through a designated set of points. Several

small weights are distributed along the length of the strip to hold it in

position on the drafting table as the curve is drawn.

The Spline curve refers to any sections

curve formed with polynomial sections satisfying specified continuity

conditions at the boundary of the pieces.

A Spline surface can be described with

two sets of orthogonal spline curves. Splines are used in graphics applications

to design curve and surface shapes, to digitize drawings for computer storage,

and to specify animation paths for the objects or the camera in the scene. CAD

applications for splines include the design of automobiles bodies, aircraft and

spacecraft surfaces, and ship hulls.

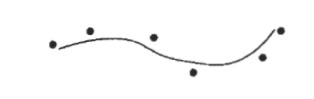

Interpolation and Approximation Splines Spline

curve can be specified by a set of coordinate positions called control

points which indicates the general shape of the curve. These control points

are fitted with piecewise continuous parametric polynomial functions in one of

the two ways. 1. When polynomial sections are fitted so that the curve passes

through each control point the resulting curve is said to interpolate the set of control points.

A set of six control points interpolated with

piecewise continuous polynomial sections

1. When

the polynomials are fitted to the general control point path without

necessarily passing through any control points, the resulting curve is said to approximate the set of control points.

A set of six control points approximated with

piecewise continuous polynomial sections

Interpolation

curves are used to digitize drawings or to specify animation paths.

Approximation curves are used as design tools to structure object surfaces. A

spline curve is designed , modified and manipulated with operations on the

control points.The curve can be translated, rotated or scaled with transformation

applied to the control points. The convex polygon boundary that encloses a set

of control points is called the convex

hull. The shape of the convex hull is to imagine a rubber band stretched

around the position of the control points so that each control point is either

on the perimeter of the hull or inside it. Convex

hull shapes (dashed

lines) for two sets of control points

Parametric Continuity Conditions

For a

smooth transition from one section of a piecewise parametric curve to the next

various continuity conditions are

needed at the connection points.

If each

section of a spline in described with a set of parametric coordinate functions

or the form x = x(u), y = y(u), z = z(u), u1<= u <= u2 -----(a)

We set parametric continuity by matching the

parametric derivatives of adjoining curve sections at their common boundary.

Zero order parametric continuity referred

to as C0 continuity, means that the curves meet. (i.e) the values of x,y, and z evaluated at u2 for the first curve

section are equal. Respectively, to the value of x,y, and z evaluated at u1 for

the next curve section.

First order parametric continuity referred

to as C1 continuity means that the first parametric derivatives of the coordinate functions in equation (a) for two

successive curve sections are equal at their joining point.

Second order parametric continuity, or C2

continuity means that both the first and second parametric derivatives of the two curve sections are equal at

their intersection.

Higher

order parametric continuity conditions are defined similarly.

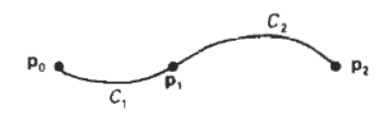

Piecewise construction of a curve by joining two

curve segments using different orders of continuity

a)Zero order continuity only

b)First order continuity only

c) Second order continuity only

Geometric Continuity Conditions

To

specify conditions for geometric continuity is an alternate method for joining

two successive curve sections.

The

parametric derivatives of the two sections should be proportional to each other

at their common boundary instead of equal to each other.

Zero

order Geometric continuity referred as G0 continuity means that the two curves

sections must have the same coordinate position at the boundary point.

First

order Geometric Continuity referred as G1 continuity means that the parametric

first derivatives are proportional at the interaction of two successive

sections.

Second

order Geometric continuity referred as G2 continuity means that both the first

and second parametric derivatives of the two curve sections are proportional at

their boundary. Here the curvatures of two sections will match at the joining

position.

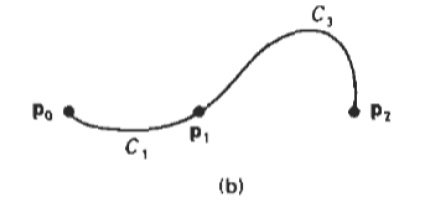

Three

control points fitted with two curve sections joined with a) parametric

continuity

b)geometric continuity where the tangent vector of

curve C3 at point p1 has a greater magnitude than the tangent vector of curve

C1 at p1.

Spline specifications There are

three methods to specify a spline representation:

1. We can

state the set of boundary conditions that are imposed on the spline; (or)

2. We can

state the matrix that characterizes the spline; (or)

3. We can

state the set of blending functions

that determine how specified geometric constraints on the curve are combined to

calculate positions along the curve path.

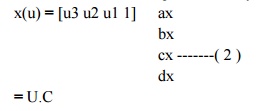

To

illustrate these three equivalent specifications, suppose we have the following

parametric cubic polynomial representation for the x coordinate along the path

of a spline section.

x(u)=axu3

+ axu2 + cxu + dx 0<= u <=1 ----------(1) Boundary conditions for this

curve might be set on the endpoint coordinates x(0) and x(1) and on the

parametric first derivatives at the endpoints x’(0) and x’(1). These boundary

conditions are sufficient to determine the values of the four coordinates ax,

bx, cx and dx. From the boundary conditions we can obtain the matrix that

characterizes this spline curve by first rewriting eq(1) as the matrix product

where U

is the row matrix of power of parameter u and C is the coefficient column

matrix. Using equation (2) we can write the boundary conditions in matrix form

and solve for the coefficient matrix C as

C = Mspline

. Mgeom -----(3) Where Mgeom in a four element column matrix containing the

geometric constraint values on the spline and Mspline in the 4 * 4 matrix that

transforms the geometric constraint values to the polynomial coefficients and

provides a characterization for the spline curve.

Matrix

Mgeom contains control point coordinate values and other geometric constraints.

We can substitute the matrix representation for C into equation (2) to obtain.

x (u) = U

. Mspline . Mgeom ------(4)

The

matrix Mspline, characterizing a spline representation, called the basis matriz is useful for transforming

from one spline representation to another.

Finally

we can expand equation (4) to obtain a polynomial representation for coordinate

x in terms of the geometric constraint parameters.

x(u) = Σ gk. BFk(u) where gk are the

constraint parameters, such as the control point coordinates and slope of the

curve at the control points and BFk(u) are the polynomial blending functions.

Related Topics