Chapter: Mechanical : Heat and Mass Transfer : Conduction

Solved Problems - Heat and Mass Transfer - Conduction

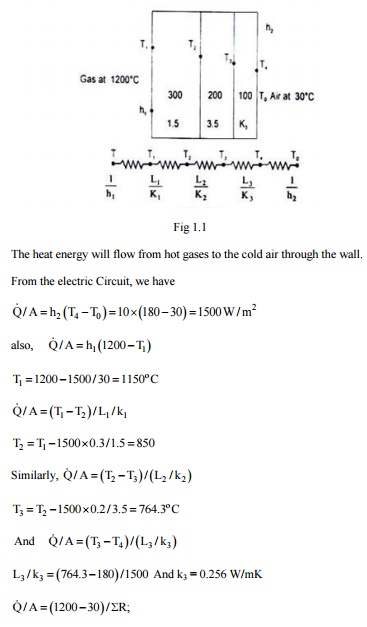

1. A composite wall

consists of three layers of thicknesses 300 mm, 200mm and100mm with thermal

conductivities 1.5, 3.5 and is W/m K respectively. The inside surface is

exposed to gases at 1200°C with convection heat transfer coefficient as 30W/m2K.

The temperature of air on the other side of the wall is 30°C with convective

heat transfer coefficient 10 Wm2K. If the temperature at the outside

surface of the wall is 180°C, calculate the temperature at other surface of the

wall, the rate of heat transfer and the overall heat transfer coefficient.

Solution: The

composite wall and its equivalent thermal circuits is shown in the figure.

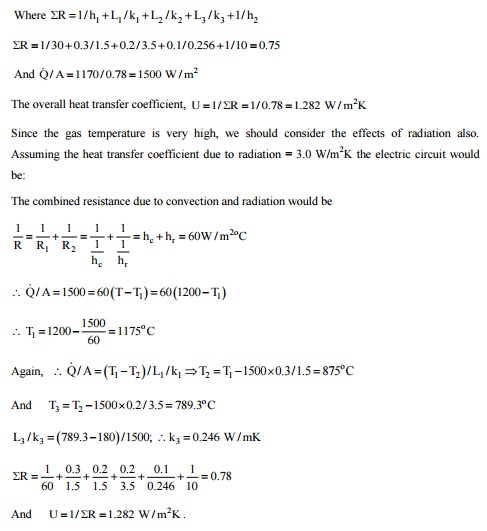

2.Derivethe General Heat Conduction

Equation for an Isotropic Solid with

Constant

Thermal Conductivity in Cartesian

coordinates.

Any physical phenomenon is generally accompanied by

a change in space and time of its physical properties. The heat transfer by

conduction in solids can only take place when there is a variation of

temperature, in both space and time. Let us consider a small volume of a solid

It should be noted that

Fourier law can always be used to compute the rate of heat transfer by

conduction from the knowledge of temperature distribution even for unsteady

condition and with internal heat generation.

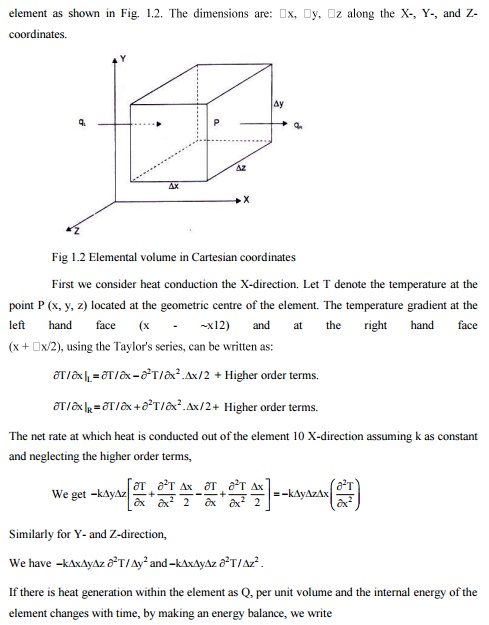

A 20 cm thick slab of aluminums (k = 230

W/mK) is placed in contact with a 15 cm thick stainless

steel plate (k = 15 W/mK). Due to roughness, 40 percent of the area is in

direct contact and the gap (0.0002 m) is filled with air (k = 0.032 W/mK). The

difference in temperature between the two outside surfaces of the plate is

200°C Estimate (i) the heat flow rate, (ii) the contact resistance, and (iii)

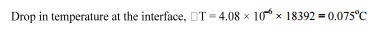

the drop in temperature at the interface.

Solution: Let

us assume that out of 40% area m direct contact, half the surface area is occupied

by steel and half is occupied by aluminums.

The physical system and its analogous electric

circuits is shown in Fig. 1.3.

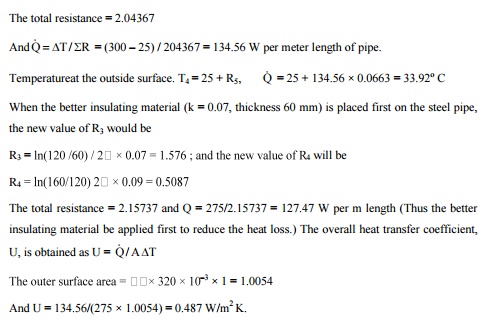

4. A steel pipe. Inside

diameter 100 mm, outside diameter 120 mm (k 50 W/m K) IS Insulated with a40mm

thick hightemperature Insulation(k = 0.09 W/m K) and another Insulation 60 mm

thick (k = 0.07 W/m K). The ambient temperature IS 25°C. The heattransfer

coefficient for the inside and outside surfaces are 550 and 15 W/m2K

respectively. The pipe carries steam at 300oC. Calculate (1) the

rate of heat loss by steam per unit length of the pipe (11) the temperature of

the outside surface .

Solution: A cross-section

of the pipe with two layers of insulation is shown Fig. 1.4with its analogous

electrical circuit.

Fig1.4A crosssection through an insulated cylinder,

thermal resistances in series.

For L = 1.0 m.

5. Steel balls 10 mm in

diameter (k = 48 W/mK), (C = 600 J/kgK) are cooled in air at temperature 35°C

from an initial temperature of 750°C. Calculate the time required for the

temperature to drop to 150°C when h = 25 W/m2K and density p = 7800 kg/m3. (AU

2012).

Solution: Characteristic

length, L = VIA = 4/3 pr3/4

pr2 = r/3 = 5 × 10-3/3m

Bi = hL/k = 25 × 5 × 10-3/ (3 × 48) = 8.68 × 10-4<<

0.1,

Since the internal resistance is negligible, we make

use of lumped capacity analysis: Eq. (3.4),

( T -T¥) / ( Ts -T¥)=exp(-Bi

Fo) ; (150 35) / (750 35) = 0.16084

\Bi × Fo = 1827; Fo =

1.827/ (8. 68 × 10-4) 2.1× 103

Or, at/

L2 = k/ ( rCL2)t

= 2100 and t = 568 = 0.158 hour

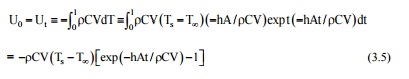

We can also compute the change in the internal

energy of the object as:

= -7800

× 600 × (4/3) p(5 × 10-3)3

(750-35) (0.16084 - 1)

= 1.47

× 103 J = 1.47 kJ.

If we allow the time't'

to go to infinity, we would have a situation that corresponds to steady state

in the new environment. The change in internal energy will be U0 - U¥ = [ rCV(

Ts -T¥) exp(-

¥)- 1] = [ rCV(

Ts -T¥].

We can also compute the instantaneous heal transfer

rate at any time.

Or. Q = - rVCdT/dt

= - rVCd/dt[ T¥+ ( Ts -T¥

)exp(-hAt/ rCV) ]

= hA( Ts -T¥)[exp(-hAt/ rCV)) and for t = 60s,

Q = 25 × 4 × 3.142 (5 ×

10-3)2(750 35) [exp( -25 × 3 × 60/5 × 10-3 ×

7800 × 600)] = 4.63 W.

6.Aluminums fins 1.5 cm

wide and 10 mm thick are placed on a 2.5 cm diameter tube to dissipate the

heat. The tube surface temperature is 170°C

ambient temperatures is 20°C.

calculate the heat loss per fin. Take h = 130 W/m2 C and K = 200 W/m2

C for aluminums.

Given

Wide of the fin b = 1.5 cm = 1.5 ´10-2 m

Thickness t = 10 mm = 10 ´10-3 m

Diameter of the tube d = 2.5 cm = 2.5 ´10-2 m

Surface temperature Tb = 170°C + 273 = 443 K

Ambient temperature T¥

= 20°C + 273 = 293 K

Heat transfer co-efficient h = 130 W/m2°C

Thermal conductivity K = 200 W/m°C

Solution

Assume fin end is insulated, so this is short fin

end insulated type problem.

Heat transfer [short fin, end insulated]

Q = (hPKA)1/2 (Tb - T¥) tan h(mL)

……..(1) [FromNoHMT.41] data

book

Where

A –Area = Breadth ´thickness

Related Topics