Chapter: Mechanical and Electrical : Power Plant Engineering : Neclear Power Plants

Sodium Graphite Reactor (SGA)

Sodium

Graphite Reactor (SGA)

Sodium

Graphite

Reactor

(SGR):

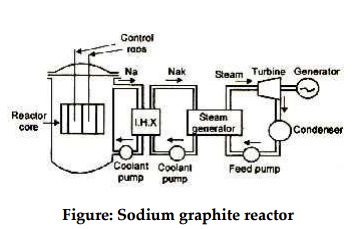

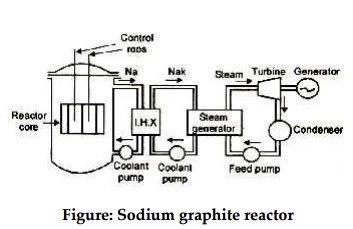

The reactor shown in figure uses two liquid metal

coolants. Liquid sodium (Na) serves as the primary coolant and an alloy of

sodium potassium (NaK) as the secondary coolant.

Sodium melts at 208°C and boils at 885°C. This

enables to achieve high outlet coolant temperature in the reactor at moderate

pressure nearly atmospheric which can be utilized in producing steam of high

temperature, thereby increasing the efficiency of the plant. Steam at

temperature as high as 540°C has been obtained by this system. This

shows that by using liquid sodium as coolant more electrical power can be

generated for a given quantity of the fuel burn up.

Secondly

low pressure in the primary and secondary coolant circuits, permits the use of

less expensive pressure vessel and pipes etc. Further sodium can transfer its

heat very easily. The only disadvantage in this system is that sodium becomes

radioactive while passing through the core and reacts chemically with water. So

it is not used directly to transfer its heat to the feed water, but a secondary

coolant is used. Primary coolant while passing through the tubes of

intermediate heat exchanges (I.H.X) transfers its heat to the secondary

coolant. The secondary coolant then flows through the tubes of steam generator

and passes on its heat to the feed water. Graphite is used as heat transfer

media have certain advantages of using liquids used for heat transfer purposes.

The various advantages of using liquid metals as heat transfer media are that

they have relatively low melting points and combine high densities with low

vapour pressure at high temperatures as well as with large thermal

conductivities.

Related Topics