Chapter: Civil : Principles of Solid Mechanics : One Dimensional Plasticity for Design

Plastic Bending

One Dimensional Plasticity for Design

In the previous pages,

a full-range plasticity solution for an EPS thick ring was developed in detail

to illustrate the fundamental concepts of plastic anal-ysis. This was possible

only because a thick ring subjected to internal or exter-nal ŌĆ£pressureŌĆØ is

essentially a one-dimensional problem in that there is only one governing

equilibrium equation since there is no variation of the field in the hoop

direction. At any stage of plastic deformation, this equation can be integrated

directly to determine the stress field. The strain and deformation field is

then determined from the behavior of the elastic rim, which has not yet

yielded.

The same is true for pure bending and

the other one-dimensional linear elastic fields of previous pages. It is also

possible to obtain full plasticity solutions in pure torsion for many cases

considered in previous pages. Combinations of lin-ear fields can also be

considered. Since limit analysis and design* of beams, shafts, frames, plates,

and many other structural systems are based on these one-dimensional plasticity

solutions, it is important to study them.

Plastic Bending

The basic assumption of the theory of

flexure as stated in Section 5.5 is that plane sections normal to the axis of

the beam remain plane so that the beam under pure bending deforms into a circle

with radius of curvature Žü. This assumption as to

the geometry of deformations has nothing to do with mate-rial properties and

requires that longitudinal strains, Ex,

in the fibers vary directly as their distance, y, from the neutral axis

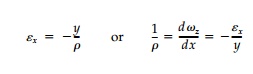

as given by Equation (5.15).

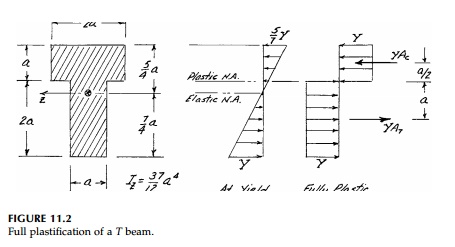

Thus, from equilibrium

requirements, a general theory can be developed for bending beyond initial

yield.*

Any prismatic beam with a cross-section

with symmetry about a vertical axis can be considered. The neutral axis,

defined as where the strain is zero, goes through the centroid in the elastic

range but may migrate as the yield-ing progresses such that horizontal

equilibrium is maintained. That is C = T or

The solution of the

general case of inelastic bending requires that these equi-librium Equations

(11.1) and (11.2) for the given stressŌĆ'strain relationship be solved by trial

and error. Two relatively simple cases are explored as chapter problems.

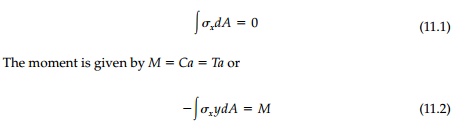

Let us consider only the case of a beam of an elastic, perfectly-plastic solid and start with a rectangular cross-section as shown in Figure 11.1. At yield of the outermost fibers, the moment MY = YI/c = Ybh2/6 = YS. As more moment is applied, the plastic zone moves toward the neutral axis and, because of our idealization of the material as an EPS, there is a sharp separa-tion leaving an elastic core at the center. If, for example, the strain at the outer surface is twice the yield strain,ŽĢ =2ŽĢY, the middle half of the beam remains elastic (Figure 11.1b) and the moment works out to be 11/48 Ybh2. At very large rotations of the cross-section, as in Figure 11.1c, the linear distribution in the small elastic core can be neglected and the stress assumed as Y throughout. Thus, this ultimate or plastic moment is

Throughout, the neutral

axis remains at mid-height because of the sym-metry around the z axis

coupled with the requirement that the compres-sion force in the top equal the

tension force in the bottom. The elastic section modulus, S, and plastic

section modulus, Z, are given in various handbooks for standard shapes

such as angles, channels, wideflange, and I beams. The ratio Z/S = MP/My is often called the shape factor, Ks.

For a rectangular cross-section then, Ks=1.5 indicating this shape has a large reserve capacity to take additional

moment beyond yield because of its inefficiency in the elastic range. For WF

and I beams, Ks = 1.12 and it takes

only 12% more moment to fully plasticize the section as to yield it.

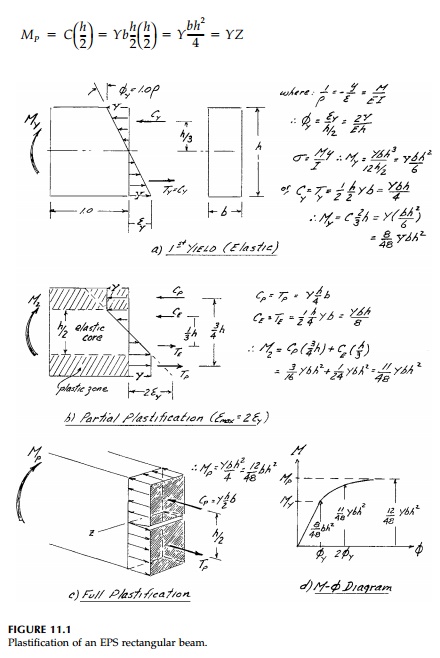

As a second example, consider the T beam in

Figure 11.2. The moment of inertia about the centroidal axis Iz = (37/12) a4 and therefore the elastic yield

moment:

As the moment increases beyond that necessary to

yield the outermost fiber at the bottom, the neutral axis must shift upward

since horizontal equilibrium requires that the compression in the top always

equal the tension in the bottom. Finally, at full plastification, when all the

fibers reach yield, C= YAc = T = YAt and the fully plastic neutral

axis is at the junction of the flange and web since, there, Ac=At = 2a2. Thus

This shape factor is

roughly the same for any T beam showing they are even less efficient

than rectangular cross-sections in the elastic range.

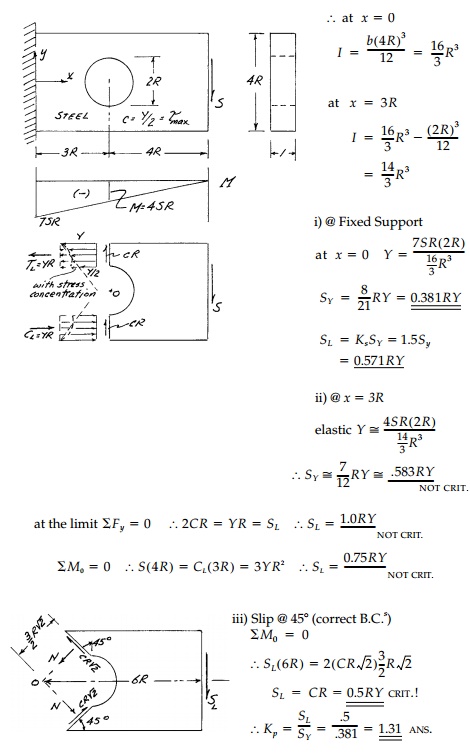

Example 11.1

A steel cantilever beam with a hole in it is loaded

with a vertical shear force (distributed parabolically) at its free end as

shown. From simple beam theory (plane sections) determine the yield load SY

. Estimate the limit load from an upper-bound approach and thereby the

plasticity factor SL/SY .

Related Topics