Chapter: Civil : Principles of Solid Mechanics : One Dimensional Plasticity for Design

Limit Analysis of Plates

Limit Analysis of Plates

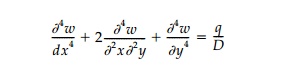

The elastic analysis of plates with a distributed

lateral load ŌĆ£q,ŌĆØ while straightforward in concept, can be extremely

complicated because of difficul-ties introduced by the boundary conditions. The

fundamental governing equation in terms of the lateral deflection, w,

is essentially a ŌĆ£two-wayŌĆØ beam equation where the

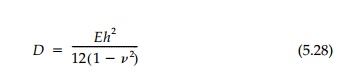

flexural rigidity of the plate

replaces the simple beam rigidity EI. As with

a beam, slopes are proportional to the first derivatives, moments to the second

derivatives, and shears to the third derivatives of the deflection. Thus the

boundary conditions of a free edge, simply-supported edge, and fixed edge can

be expressed. In theory, the elastic problem can be solved directly for

circular plates, by using Fourier series for rectangular shapes, and by

numerical methods for irregular boundaries. Elastic solutions in the form of

extensive tables of coefficients are given in the literature for rectangular

and circular plates.*

In contrast, the limit analysis of plates using the

upper-bound theorem, is straightforward and much easier than elastic analysis.

Simply assume a col-lapse mechanism and calculate the corresponding collapse

load by the energy balance or by equilibrium. While an elastic analysis may

require hours of intensive calculation, a good estimate of the limit load can

be determined in a few minutes. Equally important, a good physical feel for the

structural behav-ior of the plate is obtained in the process.

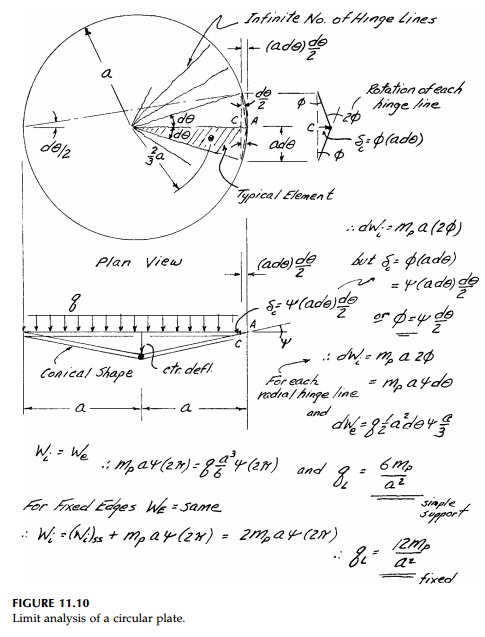

Take, for example, the simple case shown in Figure

11.10 of a circular plate of radius, a, and thickness, h, with a

uniform vertical load, q, over the entire surface. If the edge is simply

supported (free to rotate) the maximum elastic moment at the center is mr = mt = (3+v)qa2/16.

If the edge is built-in (clamped), the moment at the center is reduced to (1+v)qa2/16

while at the edge the radial moment is mr = - qa2/8

and there is a tangential or twisting moment mt = - v qa2/8.

The corresponding maximum stresses are, for a sim-ply supported plate:

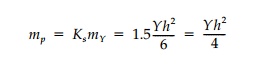

The plastic analysis follows the procedure developed

for linear structures, except that instead of elastic hinge points with a

moment capacity Mp = Ks

My , ŌĆ£hingeŌĆØ lines develop with a moment capacity per unit length.

Because of the

symmetry, the only possible failure mechanism is that, at col-lapse, the

surface is pushed downward into a cone as shown in Figure 11.10. The radial

hinge lines, along which mt =

mp, rotate 2ŽĢ doing internal work

while q over the area of a typical differential slice does external work

moving downward 4a/3. For simply supported edges, the energy balance

gives qL = 6mP/a2

and a reserve strength from first yield to collapse of KP = KsKR = 6/3.2 = 1.875. For the case where the edge is fixed, the edge itself of length 2ŽĆa

becomes a negative hinge line adding ŌłåWi = 2ŽĆampŽł to the total internal work. Thus qL = 12mP/a2 and the reserve strength qL/qY

=

KP = 12/5.33 =

2.25. Thus, not only do plates take greater loads in the elastic range by beam

action in two directions rather than one, but they have greater plastic

load-carrying capacity than beams for the same reason.

Yield-line limit analysis of plates is the flexural

counterpart to yield line or slip-surface analysis for two-dimensional planar

structures. Like the punch problem, the determination of the critical yield

line can be accomplished by trial and error or by a formal minimization

procedure for a particular type of failure mechanism. Only in special cases

like circular plates, is the determination of the exact pattern of yield

surfaces straightforward. In general, how-ever, for plates of uniform

thickness:

i. Hinge lines are straight with a constant mP = Yh2/4,

ii. Axes

of rotation are along supports,

iii. Axes

of rotation are over columns , and

iv. Hinge

lines pass through axes of rotation of adjacent slab segments.

These rules of thumb,

which help guess the critical hinge line patterns, are illustrated with a few

examples in Figure 11.11.

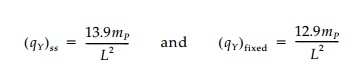

As an example of refining the pattern of hinge lines

to converge by the upper-bound theorem on the critical limit load, consider a

square plate with either pinned or fixed supports shown in Figure 11.12. The

elastic solution gives:

The simplest assumption

for the failure mechanism is diagonal hinges from the corners shown as pattern

#1. The corresponding collapse loads for the simply supported and fixed

boundary cases are calculated by equilibrium to illustrate that this approach

can be used rather than enforcing the energy balance.

However, the corners of a rectangular plate actually

would like to lift off the edge support if not restrained. Thus the moments are

negative near the corners, which act as cantilevers. To capture this, a second

hinge line pattern (#2 in Figure 11.12) with ŌĆ£corner cantileversŌĆØ or ŌĆ£corner

leversŌĆØ should be investigated. For a particular case we see, for the simply

supported plate, that by including the diagonal negative hinge at corners, the qL

is reduced by about 2.5%. Minimi-zation by successive trial and error can

reduce this further to roughly

or 9% less than for the simple Pattern #1.

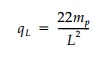

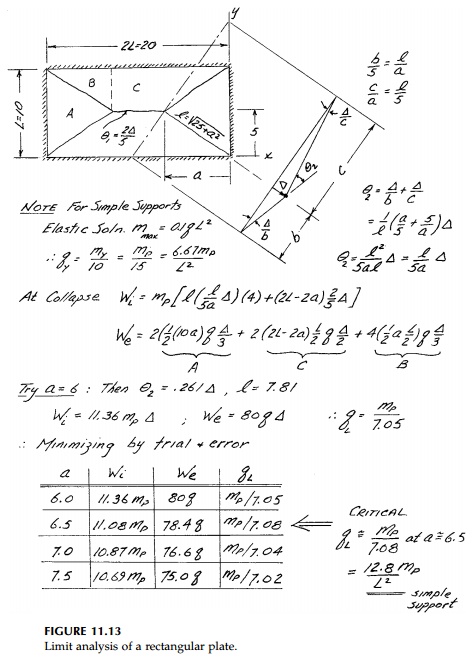

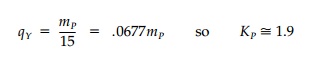

As a final example, consider a 2:1 rectangular plate

shown in Figure 11.11. Assuming the simple mechanism without including the

corner cantilevers, the limit load works out to be qL = mP/7.08 = .1412mP

. Including the corner cantilevers might reduce this 10% to qL

=

.127mP. From the elastic solution

We could now consider what happens if the edges are

fixed or if one edge were free, but these and other examples for rectangular

plates are left as chap-ter problems.

Related Topics