Chapter: Pharmaceutical Drug Analysis: Pharmaceutical Chemicals: Purity and Management

Pharmaceutical Chemicals: Purity

PURITY

The standardization of ŌĆśpharmaceutical chemicalsŌĆÖ and the dosage forms prepared therefrom

plays a vital role so that the patient gets the ŌĆśdrugŌĆÖ within the permissible

limits of potency and tolerance.

The standards for pharmaceutical chemicals and their

respective dosage forms, as laid down in, various

Official Compendia fulfil broadly the following three cardinal objectives, namely :

(a) Broad-based

highest attainable standard,

(b) Biological

response versus chemical purity, and

(c) Offical

standards versus manufacturing

standards.

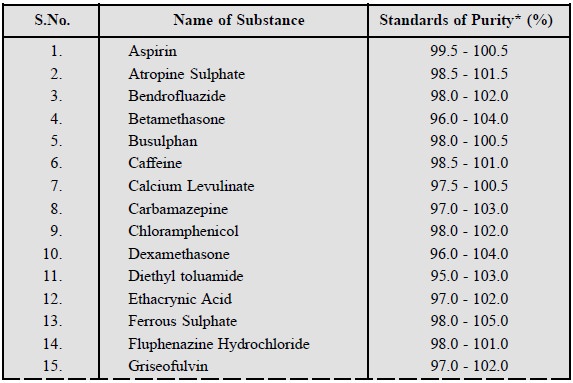

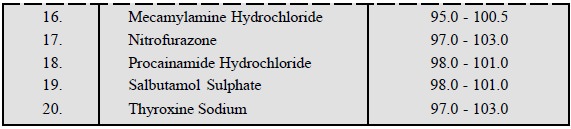

1. BROAD-BASED HIGHEST ATTAINABLE STANDARD

Keeping in view the various methods of manufacture of a

pharmaceutical substance vis-a-vis

its standards of purity, types of impurity and changing pattern of stability, a

broad-based highest attainable standard is always fixed. A few typical examples

are stated below :

2. BIOLOGICAL RESPONSE VS. CHEMICAL PURITY

Though chemical purity is the topmost priority, yet the

biological response of a pharmaceutical substance holds an equal importance. A

wide variation of active ingredients ranging between 90% in one sample and 110%

(┬▒ 10 per cent limit) in another sample could invariably be observed.

Therefore, it has become absolutely essential to lay down definite standards so

as to ensure that :

┬Ę

Different laboratories may produce reasonably reproducible

products.

┬Ę

Difference in active ingredients in various lots may be

minimised.

┬Ę

Retention of acceptable level of potency.

┬Ę

Freedom of toxicity during storage before use.

Examples :

(i) Substances

to be stored in well-closed, light-resistant containers e.g., isoniazid, nalidixic acid, nandrolone phenylpropionate,

nitrofurazone.

(ii) Substances

to be stored under nitrogen in tightly closed, light-resistant containers at a

temperature between 2┬░ and 10┬░C, e.g.,

nandrolone decanoate, nystatin, methylergometrine maleate, human normal

immunoglobulin.

(iii)

Substances to be stored in tightly-closed, light-resistant containers in a cool

place, e.g., nitrofurantoin,

pancreatin, oxyphenonium bromide.

(iv) Substances

to be stored in tightly-closed, light-resistant containers in a cool place; for

parenteral administration, the container should be sterile and sealed so as to

exclude micro-organisms. e.g.,

kanamycin sulphate, novobiocin sodium, benzylpenicillin, lincomycin

hydrochloride, chloramphenicol.

(v) Substances

to be stored in well-closed containers, at a temperature not exceeding 30┬░C, e.g., procaine penicillin, pepsin,

menthol, erythromycin.

3. OFFICIAL STANDARDS VIS-A-VIS MANUFACTURING STANDARDS

The Offical

Standards, as stipulated in the pharmacopoeias of various countries, e.g., IP BP, Eur. P., Int. P., USSRP, JP

etc., of a pharmaceutical substance take cognizance of the purity, nature,

methods and haz-ards of manufacture, precautions of storage and ultimately the

conditions under which the product is to be used.

It is a well-known fact that a pharmaceutical substance

can be prepared by adopting different routes of synthesis based upon the

dynamic ongoing research in the field of organic-reaction-mechanisms.

Relentless efforts are exerted vigorously by reputed research laboratories

across the world to look for shorter routes of synthesis bearing in mind the

cost-effectiveness of the final product. For instance : diclofenac sodium (an

NSAID) can be manufactured by two methods, one using a bromo compound as a

starting material while the other is based on a non-bromo compound.

Nevertheless, the latter product is more in demand because it is completely

devoid of bromine residues in the final product.

During the process of manufacture an unavoidable criterion

is the loss of active ingredients. Therefore, all Official Standards for pharmaceutical chemicals and dosage forms

should accomodate such losses caused due to loss in manufacture, unavoidable

decomposition and storage under normal conditions for a stipulated period.

It has become an usual

practice to include a ŌĆśdefinite overageŌĆÖ in certain dosage forms so as to

compensate the noticeable losses caused either due to manufacturing or storage

(anticipated decomposition), in order that the finished product may comply with

the prescribed offcial standards after the stipulated duration of storage.

Official standards with regard to dosage form and packs,

preservation and prevention from contamination in a variety of pharmaceutical

products, such as eye-drops, multidose injections and antiseptic creams

(external application) that may be prone to spoilage with prolonged repetitive

usage should be well defined. The official standards, in general, legislate and

control the presence of toxic impurities by prescribed ŌĆślimit testsŌĆÖ and also by more sophisticated analytical techniques

using thin-layer chromatography (TLC), high performance thin-layer

chromatography (HPTLC), gas-liquid chromatography (GLC) and high-performance

liquid chromatography (HPLC).

Related Topics