Chapter: Linear Integrated Ciruits : IC Fabrication and Circuit Configuration for Linear ICs

Monolithic diodes

Monolithic diodes:

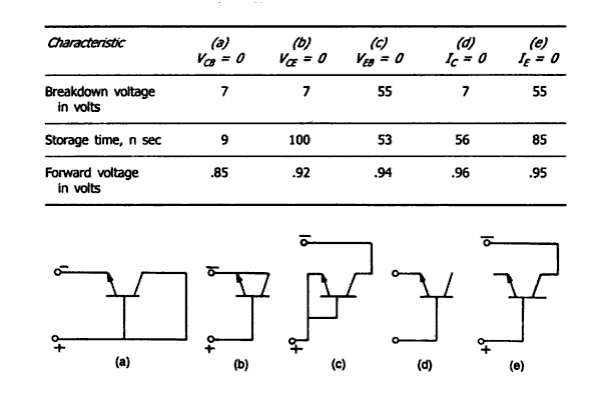

The diode

used in integrated circuits are made using transistor structures in one of the

five possible connections. The three most popular structures are shown in

figure. The diode is obtained from a transistor structure using one of the

following structures.

1.

The emitter-base diode, with collector short

circuited to the base.

2.

The emitter-base diode with the collector open and

3.

The collector –base diode, with the emitter

open-circuited.

The

choice of the diode structure depends on the performance and application

desired. Collector-base diodes have higher collector-base arrays breaking

rating, and they are suitable for common-cathode diode arrays diffused within a

single isolation island. The emitter-base diffusion is very popular for the

fabrication of diodes, provided the reverse-voltage requirement of the circuit

does not exceed the lower base-emitter breakdown voltage.

1. Integrated Resistors:

A

resistor in a monolithic integrated circuit is obtained by utilizing the bulk

resistivity of the diffused volume of semiconductor region. The commonly used

methods for fabricating integrated resistors are 1. Diffused 2.epitaxial 3.

Pinched and 4. Thin film techniques.

2. Diffused Resistor:

The

diffused resistor is formed in any one of the isolated regions of epitaxial

layer during base or emitter diffusion processes. This type of resistor

fabrication is very economical as it runs in parallel to the bipolar transistor

fabrication. The N-type emitter diffusion and P-type base diffusion are

commonly used to realize the monolithic resistor.

The

diffused resistor has a severe limitation in that, only small valued resistors

can be fabricated. The surface geometry such as the length, width and the

diffused impurity profile determine the resistance value. The commonly used

parameter for defining this resistance is called the sheet resistance. It is

defined as the resistance in ohms/square offered by the diffused area.

In the monolithic resistor, the resistance value is expressed by R = Rs 1/w

where R=

resistance offered (in ohms)

Rs =

sheet resistance of the particular fabrication process involved (in

ohms/square)

l =

length of the diffused area and w = width of the diffused area.

The sheet

resistance of the base and emitter diffusion in 200Ω/Square and 2.2Ω/square

respectively. For example, an emitter-diffused strip of 2mil wide and 20 mil

long will offer a resistance of 22Ω. For higher values of resistance, the

diffusion region can be formed in a zig-zag fashion resulting in larger

effective length. The poly silicon layer can also be used for resistor

realization.

3.

Epitaxial Resistor:

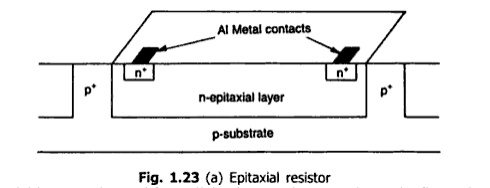

The

N-epitaxial layer can be used for realizing large resistance values. The figure

shows the cross-sectional view of the epitaxial resistor formed in the

epitaxial layer between the two N+aluminium metal contacts.

4.

Pinched resistor:

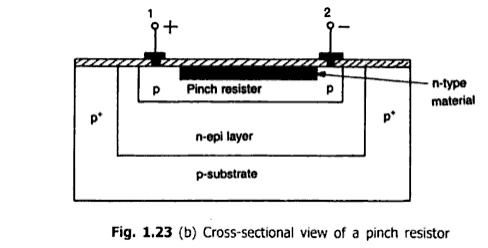

The sheet

resistance offered by the diffusion regions can be increased by narrowing down

its cross-sectional area. This type of resistance is normally achieved in the

base region. Figure shows a pinched base diffused resistor. It can offer

resistance of the order of mega ohms in a comparatively smaller area. In the

structure shown, no current can flow in the N-type material

since the

diode realized at contact 2 is biased in reversed direction. Only very small

reverse saturation current can flow in conduction path for the current has been

reduced or pinched. Therefore, the resistance between the contact 1 and 2

increases as the width narrows down and hence it acts as a pinched resistor.

5. Thin

film resistor:

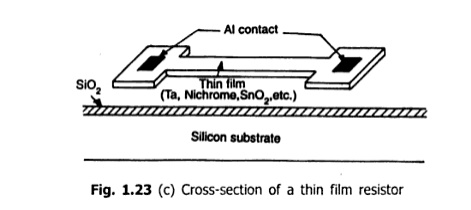

The thin

film deposition technique can also be used for the fabrication of monolithic

resistors. A very thin metallic film of thickness less than 1μm is deposited on

the silicon dioxide layer by vapour deposition techniques. Normally, Nichrome

(NiCr) is used for this process. Desired geometry is achieved using masked etching

processes to obtain suitable value of resistors. Ohmic contacts are made using

aluminium metallization as discussed in earlier sections.

The

cross-sectional view of a thin film resistor as shown in figure. Sheet

resistances of 40 to 400Ω/ square can be easily obtained in this method and

thus 20kΩ to 50kΩ values are very practical.

The

advantages of thin film resistors are as follows:

1.

They have smaller parasitic components which makes

their high frequency behaviour good.

2.

The thin film resistor values can be very minutely

controlled using laser trimming.

3.

They have low temperature coefficient of resistance

and this makes them more stable.

The thin

film resistor can be obtained by the use of tantalum deposited over silicon

dioxide layer. The main disadvantage of thin film resistor is that its

fabrication requires additional processing steps.

Related Topics