Industrial Microbiology - Industrial Production of Penicillin | 12th Microbiology : Chapter 6 : Industrial Microbiology

Chapter: 12th Microbiology : Chapter 6 : Industrial Microbiology

Industrial Production of Penicillin

Penicillin Production

Penicillin

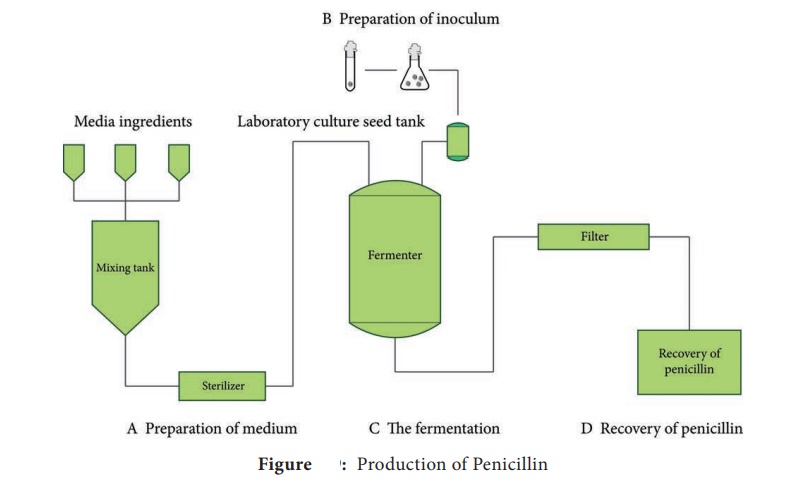

is a broad spectrum antibiotic. Penicillin is first obtained from the mould, Penicillium notatum (Figure 6.8).

Penicillium chrysogenum is a high yielding strain, used for the

commercial production of penicillin. This strain is highly unstable, so the

spore suspensions are maintained in a dormant state to prevent contamination.

Most penicillin form filamentous broth and hence is difficult to mix and it

hinders oxygen transfer due to their high viscosity. This is avoided by using

bubble columns air lift reactors which agitates the medium providing even

oxygen distribution.

Penicillin has a basic structure 6-amino penicillanic acid

6-(APA). It consists of a thiazolidine ring with a condensed β-lactum ring. It

carries a variable side chain in position 6. Natural penicillins are produced

in a fermentation process without adding any side chain precursors. If a side

chain precursor is added to the broth, desired penicillin is produced and it is

called bio-synthetic penicillin.

Semi synthetic penicillin is one in which, both fermentation and

chemical approach are used to produce useful pencillins. It can be taken orally

and active against gram negative bacteria. (eg) Amphicilin. Nowadays, semi synthetic

pencillins makeup the bulk of the penicillin market.

Infobits

In later (1939) using (Flemings’ work) Howard Florey and Ernst

Chain managed to purify penicillin in a powdered form. In 1941, they

successfully treated a human. In 1943, they produced penicillin on a large

scale. This helped immensely to treat causalities during the 2nd World War ww1

that had bacterial inflations due to their wounds.

The main objective of producing semi synthetic penicillin is to generate compounds with improved

properties. (eg) acid stability, Resistance to enzymic degradation, broader

spectrum of activity. Here side chain is removed to form (6 - APA) via

immobilization in a column of penicillin acylase. Penicilln is converted to

(6-APA) and phenyl acetic. Then it is chemically to acylated produce Semi

Synthetic Pencillin.New kinds of synthetic penicillin can also be produced

which are readily absorbed by the intestine compared to natural penicillin.

Example: Phenithicilin.

The

initial strain of Penicillium chrysogenum (NRRL, 1951) was low yielding strain

and so it is was treated with mutagenic agents such as X-rays, UV right and

some other repeated methods to get a high yielding strain Q-176.

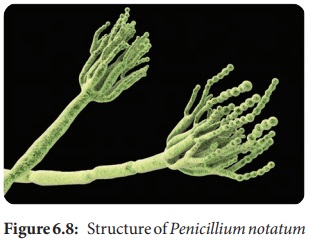

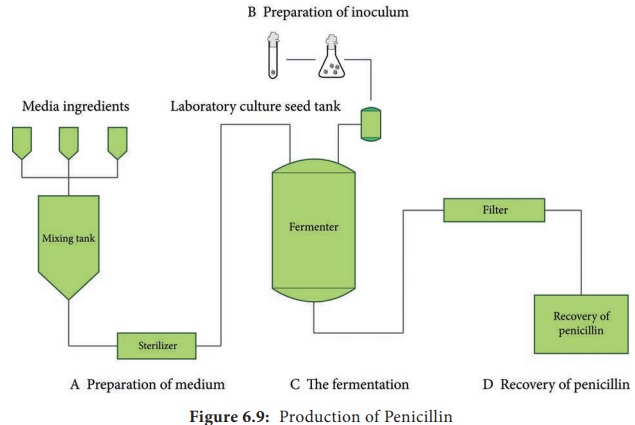

Production methods

Penicillin

production is done by one of the following.

1. Surface

culture

2. Submerged

fermentation process

Inoculum Production

Inoculation methods

To

inoculate fermentation medium one of the following methods can be employed.

1. Using

dry spores to seed the fermentation medium.

2. Making

suspension along with non toxic wetting agent like Sodium lauryl sulphate and

inoculating germinated organism

3. Using

pellet inocula obtained by the germination of spores

The

lyophilized spores (or) spores in well sporulated frozen agar slant are

suspended in water or in a dilute solution of a nontoxic wetting agent.

(1:10,000 sodium lauryl sulphonate)

↓

Spores

are then added to a bottles containing wheat bran solution It is incubated for

5-7 days at 24°C for heavy sporulation

↓

The resulting spores are then transferred to

production tank

↓

The micro

organism in the inoculumtank is checked for contamination.

Production process

The production

tanks are inoculatedwith a mycelial growth

↓

Production

medium contains following medium components.

Carbon

source as Lactose, Nitrogen source as Ammonium sulphate, Acetate or Lactate

(Corn steep liquor is the cheap and easy source of nitrogen)

Mineral

sources as K, P (Potassium di hydrogen phosphate), Mg, S (Magnesium sulphate),

Zn, Cu(Copper sulphate) (Corn steep liquor supply some of these minerals)

Precursor

(Example: phenyl acetic acid)is added to the medium

↓

Antifoam

agent (Example: corn orsoybean oil) is added before sterilization

The

sufficient aeration and agitation is given and are incubated at 25°C to 26°C

for 3 to 5 days at PH range of 7 to 7.5

Penicillin Production

Process

of penicillin production occurs in three phases

First

phase: Growth of mycelium occurs in this phase where the yield of antibiotic is

low. The pH increases due to the release of NH3.

Second

phase: In this phase, intense synthesis of penicillin occurs due to rapid

consumption of Lactose and Ammonium nitrogen. The mycelial mass increases and

the pH remain unchanged (Figure 6.9).

Third

phase: In this phase, the concentration of antibiotics decreases in the medium.

Autolysis of mycelium starts, liberating Ammonia leading to slight rise in pH.

Recovery

After penicillin

fermentation, the brothis filtered on rotary vacuum filte

↓

Mycelium

is separated

↓

To the

broth sulphuric acid or phosphoric acid is added

↓

Penicillin

is converted into anionic form

↓

It is

extracted in counter current solvent extractor, by using organic solvent, amyl

acetate, methyl isobutyl ketone)

↓

It is

then back extracted with water from the organic solvent by adding potassium or

sodium hydroxide

↓

Shifts between

water and solvent aid in the purification of penicillin

↓

The

resulting sodium or potassium penicillin is then crystallized

↓

Then it

is washed, dried and used for commercial purpose

Related Topics