Basic Design, Process, Downstream Processing, Media Used in the Industrial Productions | Industrial Microbiology - Fermentors | 12th Microbiology : Chapter 6 : Industrial Microbiology

Chapter: 12th Microbiology : Chapter 6 : Industrial Microbiology

Fermentors

Fermentors

The main function of a fermenter is to provide a suitable environment in which an organism can efficiently produce a target product. Most of them are designed to maintain high biomass concentrations, which are essential for many fermentation processes. Fermentor design, quality of construction, mode of operation and the level of sophistication largely depend upon the production organism, the optimal operating conditions required for target product formation, product value and the scale of production. The performance of any fermenter depends on many factors, but the key physical and chemical parameters that must be controlled are agitation rate, oxygen transfer, pH, and temperature and foam production.

HOTS

What will happen if antifoam agents

are not used in the Fermentation process?

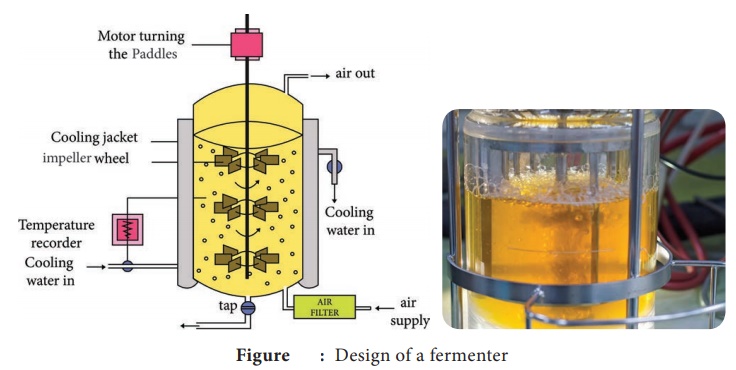

Basic Design of a Fermenter

The materials used for construction of

fermenter withstand repeated steam sterilization and are nontoxic. The reaction

vessel is designed to withstand vacuum or else it may collapse while cooling.

The internal surface is smooth an corrosion resistant. Either stainless steel

or glass is used for construction.

Conventional bioreactors are

cylindrical vessels with dome top and bottom (Figure 6.5).

It is surrounded by a jacket and

sparger at the bottom through which air is introduced. The agitator (for mixing

of cells and medium) shaft is connected to a motor at the bottom. It has ports

for pH, temperature, dissolved Oxygen sensors for regulation. Antifoam agents

like animal vegetable oil, lard oil, corn oil and soya bean oil are used to

control the foam. Modern fermentors are usually integrated with computers for

efficient process monitoring and data acquisition. Parts of the fermenter and

their functions are given in Table 6.2.

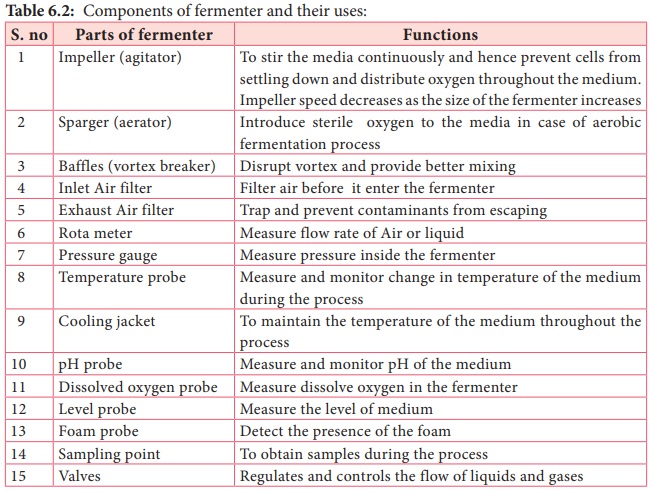

Table 6.2: Components of fermenter and

their uses:

Components of fermenter and their uses:

Parts of fermenter: Functions

1. Impeller (agitator): To stir the media continuously and

hence prevent cells from settling down and distribute oxygen throughout the

medium. Impeller speed decreases as the size of the fermenter increases

2. Sparger (aerator): Introduce sterile oxygen to the media

in case of aerobic fermentation process

3. Baffles (vortex breaker): Disrupt vortex and

provide better mixing

4. Inlet Air filter: Filter air before it enter the

fermenter

5. Exhaust Air filter: Trap and prevent contaminants from

escaping

6. Rota meter: Measure flow rate of Air or liquid

7. Pressure gauge: Measure pressure inside the fermenter

8. Temperature probe: Measure and monitor change in

temperature of the medium during the process

9. Cooling jacket: To maintain the temperature of the

medium throughout the process

10. pH probe: Measure and monitor pH of the medium

11. Dissolved oxygen probe: Measure dissolve oxygen in the

fermenter

12. Level probe: Measure the level of medium

13. Foam probe: Detect the presence of the foam

14. Sampling point: To obtain samples during the process

15. Valves: Regulates and controls the flow of

liquids and gases

There are different types of

fermentor used in industrially micro biology which includes

1. Stirred tank bioreactor

2. Tower bioreactors

3. Air lift bioreactors

4. Packed–bed bioreactors

5. Fluidized bed bioreactors

6. Photo bioreactors

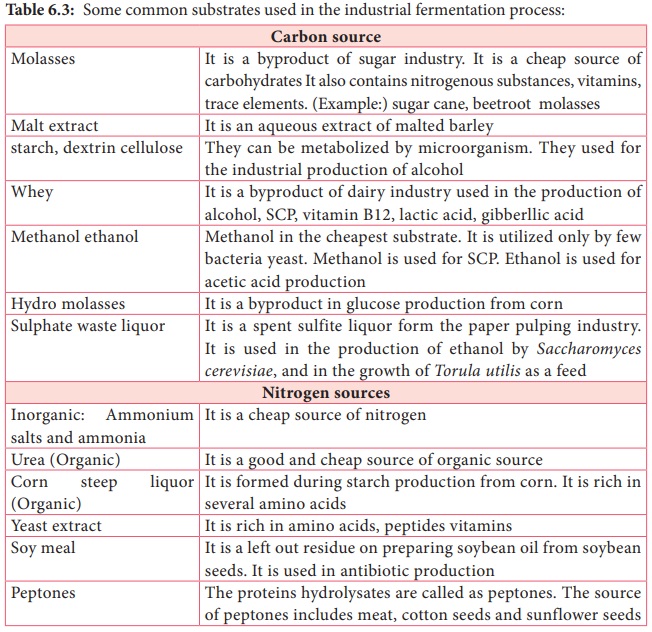

Media Used in the Industrial Productions

Fermentation Medium

Most

fermentation requires liquid media, often referred to as broth, although some

solid-substrate fermentations are also operated. Fermentation media must

satisfy all the nutritional requirements of the microorganism and fulfill the

technical objectives of the process. Animal fats and plant oils are also

incorporated into some media, often as supplements to the main carbon source.

Medium

used for large scale production should have the following characteristics.

1. It

should be cheap and easily availabe

2. It

should maximize the growth ofhe microorganism productivity and the rate of

formation of the desired product

3. .It

should minimize the formation of undesired products

It should

contain carbon source,nitrogen source, energy source, micro nutrients required

for the industrial production. Table 6.3 shows common substances used in the

industrial fermentation process.

Waste

products from other industrial processes such as molasses, ligno cellulosic

waste, and corn steep liquor are generally used as substrates for industrial

fermentation.

Apart

from carbon and nitrogen sources, some other components like minerals,

vitamins, growth factors are also used in Industrial fermentations.

Minerals

Normally,

sufficient quantities of cobalt, copper, iron, manganese, molybdenum, and zinc

are present in the water supplies, and as impurities in other media

ingredients. For example, corn steep liquor contains a wrange of minerals that

will usually satisfy the minor and trace mineral needs

Vitamins

and growth factors

Many bacteria can synthesize all necessary vitamins from basic elements. For other bacteria, filamentous fungi and yeasts, they must be added as supplements to the fermentation medium. Most natural carbon and nitrogen sources also contain at least some of the required vitamins as minor contaminants. Other necessary growth factors, amino acids, nucleotides, fatty acids and sterols, are added either in pure form or, for economic reasons, as less expensive plant and animal extracts.

Precursors

Some

fermentation must be supplemented with specific precursors, notably

forsecondary metabolite production. When required, they are often added in

controlled quantities and in a relatively pure form. Examples: Phenyl acetic

acid or phenylacetamide added as side chain precursors in penicillin

production.

Large Scale Production

Basic Steps of Industrial Fermentation

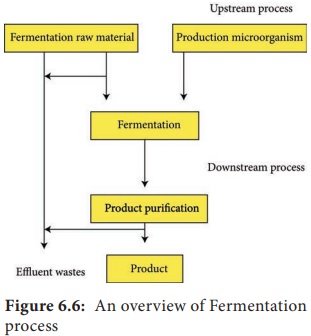

Successful

development of a fermentation process and fermentors requires major contributions

from a wide range of other disciplines, particularly biochemistry, genetics,

molecular biology, chemistry, chemical engineering and process engineering,

mathematics and computer technology. A typical operation involves both upstream

processing (USP) and downstream processing (DSP) stages (Figure 6.6).

Upstream Processing

It is the

first step in which biomolecules like bacteria or other cells are grown in a

fermentor. Upstream processing involves inoculation development, scale up,

medium preparation and sterilization of media and fermentation process.

Inoculum development

It is a

preparation of a population of micro organisms from a stock dormant culture to

a state useful for inoculating a final production fermentor.

It is a

critical stage in fermentation process.

It is a

stepwise sequence employing increasing volume of media.

Inoculum

media is usually balanced for rapid cell growth and not for product formation.

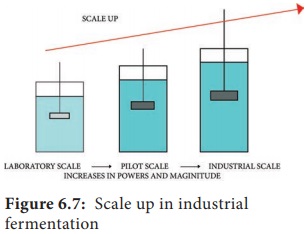

Inoculum scale up

It is the

preparations of the seed culture in amounts sufficient to be used in the larger

fermenter vessel. It involves growing the microorganisms obtained from the pure

stock culture in several consecutive fermenter. By doing this, the time

required for the growth of microbes in the fermenter is cut down, so that the

rate of productivity is increased. The seed culture obtained is then used for

inoculation in fermentation medium. The size of the inoculums is generally

1–10% of the total volume of the medium.

In

general, fermentation/ bioprocess techniques are developed in stages starting

from a laboratory and finally leading to an industry. The phenomenon of

developing industrial fermentation process in stages is referred to as

scale–up. Scale–up is necessary for implementing new fermentation technique

developed using mutant organisms.

The very

purpose of scale–up is to develop optimal environmental and operating

conditions at different levels for a successful fermentation industry where

conditions like substrate concentration agitation and mixing, aeration, power

consumption and rate of Oxygen transfer are studied. In a conventional

scale–up, a fermentation technique is developed in 3–4 stages. The initial

stage involves a screening process using Petri dishes or Erlenmeyer flasks

followed by a pilot project to determine the optimal operating conditions for a

fermentation process with a capacity of 5–200 litres. The final stage involves

the transfer of technology developed in the laboratory to industry. (Figure

6.7)

It has to

be continuously noted that a fermentation process that works well at the

laboratory scale may work poorly or may not work at all on industrial scale.

Therefore it is not always possible to blindly apply the laboratory conditions

of a fermentation technique developed to industry.

At the

laboratory scale, one is interested in the maximum yield of the product for

unit time. At the industry level, besides the product yield, minimal operating

cost is another important factor for consideration.

Preparation and sterilization of media

According

to the specific industrial production basic components needed to carry out

fermentation are selected as per the required volume.

Medium

components should be free from contamination. So all the medium components

employed in the fermentation process are sterilized. Sterilization is mostly

carried out by applying heat and to lesser extent other physical methods,

chemical methods (disinfectants) and radiation (using UV rays, γ rays). Batch

Sterilization is carried out at 121°C (20 to 60 mins) where as continuous

sterilization is done at 140°C for (30 to 120 secs). Much energy is wasted on

batch sterilization on compared with continuous sterilization nearly 80 to 90%

of energy saved during this process. Air and heat sensitive components are

sterilizied by membrane filters.

Fermentation Process

It

involves the propagation of the microorganism and the production of the desired

product. Fermentation process is divided depending on the feeding strategy of

the culture and medium as follows.

i. Batch

Fermentation

ii. Continuous

Fermentation

iii. Fed

batch Fermentation

i. Batch Fermentation

The

medium and culture are initially fed into the vessel and it is then closed.

After that, no components are added apart from Oxygen. The pH is adjusted

during the course of process by adding either acid or alkali. The fermentation

is allowed to run for a predetermined period of time and the product is

harvested at the end. Foaming is controlled by adding antifoam agents such as

palm oil or soybeans oil. Heat generated is regulated by providing water

circulation system around the vessel for heat exchange.

ii. Continuous fermentation

This is

an open system. It involves the removal of culture medium continuously and

replacement of them with a fresh sterile medium in a bioreactor. reactors which

include chemo stat and turbid stat bioreactors are used. Examples: production

of antibiotics, organic solvents, beer, ethanol and SCP

iii. Fed batch system

It is a combination of both batch and continuous systems. In this, additional nutrients are added to the fermentors as the fermentation is in progress. This extends the time of operation, but the products are harvested at the end of the production cycle as in batch fermenter.

HOTS Why does industry prefer continuous culture?

Followed

by the fermentation, production, products are harvested or separated by

downstream processing.

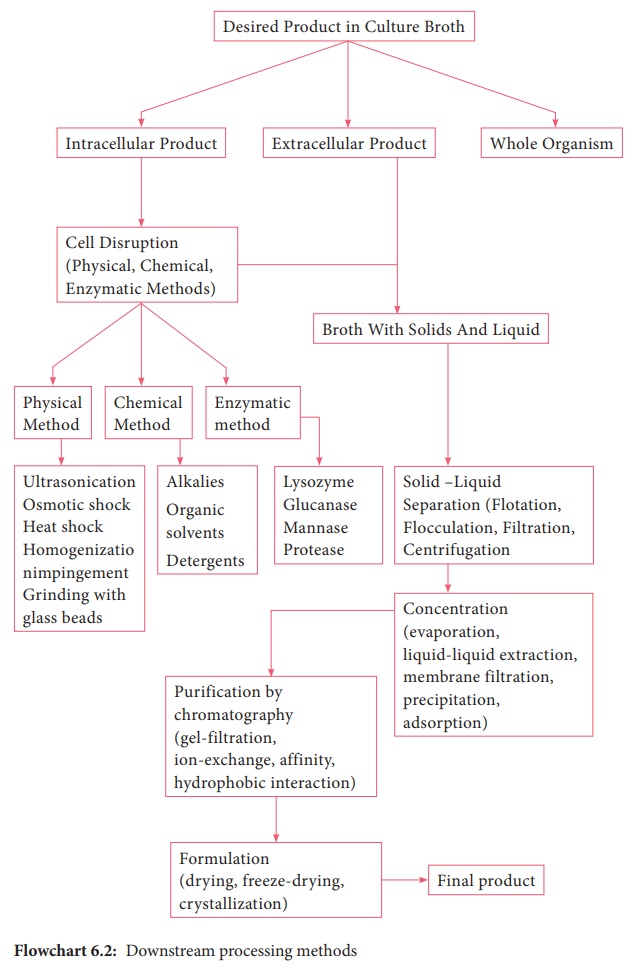

Downstream Processing

The various processes used for the actual recovery of useful

products from fermentation or any other industrial processes are called downstream

processing. The cost of downstream processing (DSP) is often more than 50% of

the manufacturing cost, and there is product loss at each step of DSP.

Therefore, the DSP should be efficient, involve as few steps as possible and be

cost-effective. Methods involved in the downstream processing are outlined in

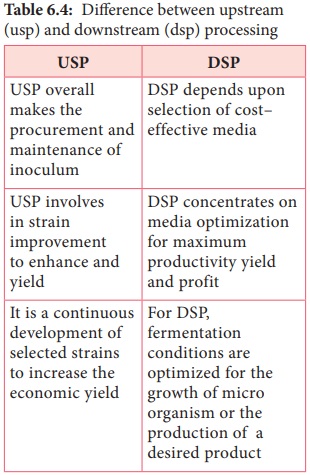

the flowchart (6.2). Table 6.4 shows Difference between upstream and downstream

processing.

Table 6.4: Difference between upstream (usp) and downstream (dsp)

processing

USP

• USP overall makes the procurement and maintenance of inoculum

• USP involves in strain improvement to enhance and yield

• It is a continuous development of selected strains to increase

the economic yield

DSP

• DSP depends upon selection of cost–effective media

• DSP concentrates on media optimization for maximum productivity

yield and profit

• For DSP, fermentation conditions are optimized for the growth of micro organism or the production of a desired product

Related Topics