Chapter: Design of Electrical Machines : Transformers

Important Short Questions and Answers: Design of Electrical Machines - Transformers

TRANSFORMERS

1.

Define transformation ratio.

It

is defined as the ratio of secondary terminal voltage to primary terminal

voltage.

It is denoted by k.

K = Vs /Vp = Ts / Tp = Ip / Is

2.

Name the types of transformer.

Based

upon construction, the types are

Core type and

shell type transformer

Based

on applications,

the types are

Ø

Distribution

transformers

Ø

Power

transformers

Ø

Special

transformers

Ø

Instrument

transformers

Ø

Electronics

transformers

Based

on the type of connection,

the types are

Ø

Single

phase transformer

Ø

Three

phase transformer

Based

on the frequency range,

the types are

Ø

Power

frequency transformer

Ø

Audio

frequency transformer

Ø

UHF

transformers

Ø

Wide

band transformers

Ø

Narrow

band transformer

Ø

Pulse

transformer

Based

on the number of windings,

the types are

Ø

Auto

transformer

Ø

Two

winding transformer

3.

Define windows space factor or

window area constant.

It is defined as the ratio of the

are of copper in the window to the window area.

Kw

= Ac / Aw < 1

Ac is the area of copper in m2

Aw is the area of window in m2

4. Define iron space factor.

It is defined as the ratio of gross

core area to the area of the circumscribing circle.

Kis

= Agi / Ace < 1

Agi

is the gross core area in m2

Ace

is the area of circumscribing circle

in m2

5.

What is a function of a transformer?

Ø

It

increases or decreases the voltage at same frequency.

Ø

It

transforms energy from one winding to other winding at constant frequency.

Ø

It

is used in electronic circuits with rectifying units to convert ac to dc.

Ø

It

provides isolation between to electrical circuits.

6.

What is the function of transformer

oil?

Ø

It

provides cooling.

Ø

It

acts as insulation.

Ø

It

protects the paper from dirt and moisture.

7.

What is the cause of noise in

transformer?

Ø

Mechanical

forces developed during working

Ø

Loosening

of stampings in the core

Ø

Expansion

and contraction of oil level

8.

What are the properties of

transformer oil?

Ø

High

dielectric strength

Ø

High

resistivity and density

Ø

Low

viscosity

Ø

Low

impurity

Ø

Reasonable

cost and flash point

9.

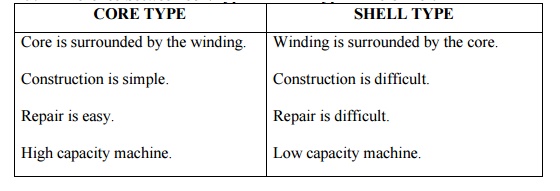

Difference between core type and shell type transformer.

10.

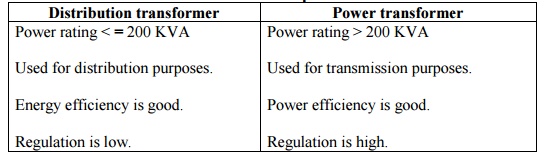

Difference between distribution and power transformer.

11.

Mention the important characteristics

desirable in transformer oil.

Ø

Electric

strength

Ø

Resistance

to emulsion

Ø

Viscosity

Ø

Purity

Ø

Flash

point

Ø

Sludge

formation

12.

Why is transformer oil used as

cooling medium?

When transformer oil is used as

coolant, the heat dissipation by convection is 10 times more than the

convection due to air specific heat dissipation by convection due to air = 8 W/

m2 – C.

Specific heat dissipation by

convection due to oil = 80 to 100 W/ m2 – C.

13.

Mention the factors to be considered for selecting the cooling method of a

transformer.

The choice of cooling method depends

on KVA rating of transformer, size, application and the site condition where it

has to be installed.

14.

List the different methods of

cooling of transformer.

Ø

Air

natural

Ø

Air

blast

Ø

Oil

natural

Ø

Oil

natural – air forced

Ø

Oil

natural water forced

Ø

Forced

circulation of oil

Ø

Oil

forced – air natural

Ø

Oil

forced – air forced

Ø

Oil

forced – water forced

15.

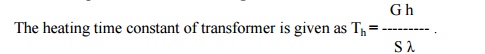

Give an expression for the heating time constant of transformer.

Where G is weight, h is specific

heat, λ is the specific heat dissipation.

16.

Why cooling tubes are are provided?

Cooling tubes are provided to

increase the heat dissipating area of the tank.

17.

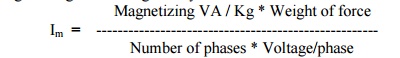

Give the expression for magnetizing current.

The magnetizing current is given by

18.

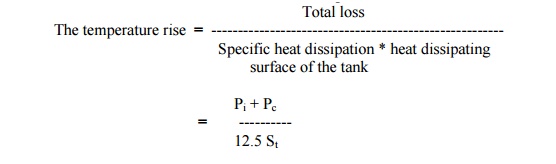

Write the expression for temperature rise in plain walled tanks.

where Pi = iron loss ; Pc = copper loss ; St = Heat dissipating surface of

the tank

19.

Why plain walled tanks are not used for large output transformers?

The plain walled tanks are not used

for large output transformers as they are not sufficient to dissipate losses.

This is because volume and hence losses increase as cube of linear dimensions

while the dissipating surface increases as the square of linear dimensions.

Thus an increase in rating results in an increase in loss to be dissipated per

unit area giving a higher temperature rise.

20.

How is leakage reactance of winding estimated?

It is estimated by primarily

estimating the distribution of leakage flux and the resulting flux leakages of

the primary and the secondary windings. The distribution of the leakage flux

depends upon the geometrical configuration of the coils and the neighboring

iron masses and also on the permeability of the iron.

21.

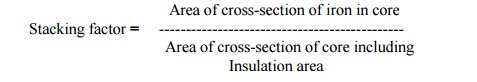

Define stacking factor and give its typical value.

Its typical value is 0.9.

22.

Why stepped cores are used in transformers?

When stepped cores are used, the

diameters of the circumscribing circle is minimum for a given area of the core,

which helps in reducing the length of mean turn of the winding with consequent

reduction in both cost of copper and copper loss.

23.

What is the range of flux densities used in the design of a transformer?

When hot rolled silicon steel is

used,

Ø

Bm

= 1.1 to 1.4 Wb / m2 for distribution transformer

Ø

=

1.2 to 1.5 Wb / m2 for power transformer When cold rolled silicon

steel is used,

Ø

Bm

= 1.5 Wb / m2 for up to 132 KV transformer

Ø

=

1.6 Wb / m2 for 132 KV to 275 KV transformer

Ø

=

1.7 Wb / m2 for 275KV to 400 KV transformer

24.

Name the factors to be considered to

choose the type of winding for a core type transformer.

Ø

Current

density

Ø

Short

circuit current

Ø

Surge

voltage

Ø

Impedance

Ø

Temperature

rise

Ø

Transport

facilities

25.

Give typical values of core area

factor for various types of transformers.

Core area factor ( Kc )

for various transformers:

Ø

Square

core Kc = 0.45

Ø

Cruciform

core Kc = 0.56

Ø

Three

stepped core Kc = 0.6

Ø

Four

stepped core Kc = 0.62

26.

List the assumptions made for

calculation of leakage flux and leakage reactance.

Ø

The

primary and secondary windings have an equal axial length

Ø

The

flux paths are parallel to the windings along the axial height

Ø

Primary

winding mmf is equal to secondary winding mmf

Ø

Half

of the leakage flux in the duct links with each winding

Ø

The

length of the mean turn of the windings are equal

Ø

The

reluctance of flux path through yoke is negligible

27.

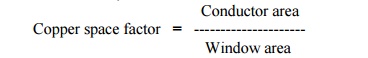

Define copper space factor.

For a transformer, it is the ratio

of conductor area and window area.

28.

Name the various types of cross section

used for core type transformer.

Ø

Square

Ø

Rectangle

Ø

Cruciform

and

Ø

Multi

stepped cores

29.

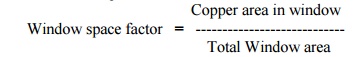

What is window space factor?

The window space factor is defined

as the ratio of copper area in window to total window

Window space factor = area. Copper area in window / Total

Window area

30.

How the area of window is calculated?

Are of the window (Aw) = Height of

window (Hw) * Width of window (Ww).

31.

Why are the cores of large transformers built up of circular cross-section?

The excessive leakage fluxes produced

during short circuit and over loads develop mechanical stresses in the coils.

These forces are radial in circular coils and there is no tendency for the coil

to change its shape. But in rectangular coils, these forces are perpendicular

and tend to deform the coil.

32.

Give the expression for window width that gives the maximum output.

The width of the window for maximum

output is

Ww = D - d = 0.7 d.

Where D = distance between adjacent

limbs d = width occupied by iron

33.

Give the expression for KVA rating of a single and three phase transformer.

Rating of a single phase & three

phase transformer in KVA is given as

Q

= 2.22 f Bm δ Kw Aw Ai * 10-3

Where f = frequency, Hz

Bm = maximum flux

density, Wb/m2

δ = current density, A/mm2

Kw = Window space factor

Aw = Window area, m2

Ai = Net core area, m2

34.

Mention different types of low

voltage windings.

Ø

Cylindrical

windings

Ø

Helical

winding

35.

What is the range of efficiency of a

transformer?

The efficiency will be in the range

of 94% to 99%.

36.

In transformers, why the low voltage

winding is placed near the core?

The winding & core are both made

of metals and so insulation has to be placed in between them. The thickness of

insulation depends on the voltage rating of the winding. In order to reduce the

insulation requirement the low voltage winding is placed near the core.

37.

What are the disadvantages of stepped cores?

With large number of steps a large

number of different sizes of laminations have to be used. This results in

higher labor charges for shearing and assembling different types of

laminations.

38.

What is the objective behind using

sheet steel stampings in the construction of electrical machines?

The stampings are used to reduce the

eddy current losses. The stampings are insulated by a thin coating of varnish,

hence when the stampings are stacked to form a core, the resistance for the

eddy current is very high.

39.

What type of steel is commonly used

for the core of transformer?

The hot rolled and cold rolled

silicon steel with 3 to 5%silicon are used for the laminations of the core of

transformers. The hot rolled silicon steel allows a maximum flux density of

1.45 Wb/m2 and the cold rolled silicon steel permits a maximum flux

density of 1.8 Wb/m2.

40.

What is tertiary winding?

Some three phase transformers may

have a third winding called tertiary winding apart from primary and secondary.

It is also called auxiliary winding or stabilizing winding.

The tertiary winding is provided in

a transformer for any one of the following reasons:

Ø

To

supply small additional load at a different voltage

Ø

To

give supply to phase compensating devices such as capacitors which work at

different voltage

Ø

To

limit short circuit current

Ø

To

indicate voltage in high voltage testing transformer

41.

How the tertiary winding is

connected? Why?

The tertiary winding is normally

connected in delta. When the tertiary is connected in delta, the unbalance in

the phase voltage during unsymmetrical faults in primary or secondary is

compensated by the circulating currents flowing in the closed delta.

42.

What are the salient features of

distribution transformer?

Ø

The

distribution transformers will have low iron loss and higher value of copper

loss.

Ø

The

capacity of transformers will be up to 500 KVA

Ø

The

transformers will have plain walled tanks are provided with cooling tubes or

radiators

Ø

The

leakage reactance and regulation will be low.

42.

What types of forces acts on the

coils of a transformer in the event of a short circuit on a transformer?

During short circuit conditions the

radial forces will be acting on the coil, which is due to short circuit

currents.

43.

What is the range of current

densities used in the design of transformer winding?

The choice of current density

depends on the allowable temperature rise, copper loss and method of cooling.

The range of current density for various types of transformers is given below:

Ø

δ

= 1.1 to 2.2 A/mm2 - For

distribution transformers

Ø

δ

= 1.1 to 2.2 A/mm2 - For

small power transformers with self oil cooling

Ø

δ

= 2.2 to 3.2 A/mm2 - For

large power transformers with self oil cooling

δ = 5.4 to 6.2 A/mm2 - For large power transformers

with forced circulation of oil

44.

How the heat dissipates in a transformer?

The heat dissipation in a

transformer occurs by conduction, convection and Radiation.

45.

How the leakage reactance of a transformer is reduced?

In transformers the leakage

reactance is reduced by interleaving the high voltage, and low voltage winding.

46.

How the magnetic curves are used for calculating the no-load current of a

transformer?

The B –H curve can be used to find

the mmf per metre for the flux densities in yoke and core. The loss curve can

be used to estimate the iron loss per Kg for the flux densities in yoke and

core.

47.

What is conservator?

A conservator is a small cylindrical

drum fitted just above the transformer main tank. It is used to allow the expansion

and contraction of oil without contact with surrounding atmosphere.

When conservator is fitted in a

transformer, the tank is fully filled with oil and the conservator is half

filled with oil.

48.

Why silica gel is used in breather?

The silica gel is used to absorb the

moisture when the air is drawn from atmosphere into the transformer.

49.

What are the merits and demerits of

using water for forced cooling of transformers?

The advantage in forced water

cooling is that large amount of heat can be removed quickly from the

transformer.

The disadvantage in forced water

cooling is that the water may leak into oil and the oil may be contaminated.

50.

In mines applications transformers

with oil cooling should not be used, why?

The oil used for transformer cooling

is inflammable. Hence leakage of cooling oil may create fore accidents in

mines. Therefore oil cooled transformers are not used in mines.

Related Topics