Chapter: Mechanical : Manufacturing Technology : Theory Of Metal Cutting

Important Questions and Answers: Theory of Metal Cutting

THEORY OF METAL CUTTING

1. Define Metal Cutting .

Metal cutting or machining is the

process of by removing unwanted material from a block of metal in the form of

chips.

2. What are the important

characteristics of materials used for cutting tools?

High

red hardness High wear

resistance

Low

frictional co- efficient

High

toughness

High

thermal conductivity.

3. How do you define tool life?

The time period between two

consecutive resharpening, with which the cuts the material effectively is

called as tool life.

4. What is tool signature?

The various angles of tools are

mentioned in a numerical number in particular order. That is known as tool

signature.

5. What is the effect of back rack

angle and mention the types?

Back rake angle of tool is increases the strength

of cutting tool and cutting action. It can be classified in to two types.

1. Negative

Rake angle.

2. Positive

rake angle.

6. Explain the nose radius?

Joining of side and end cutting

edges by means of small radius in order to increase the tool life and better

surface finish on the work piece.

7. What are all conditions for

using positive rake angle?

1. To

machine the work hardened materials.

2. To

machine low strength ferrous and non-ferrous metals.

3. To

machine long shaft of small diameters.

4. To

machine the metal blow recommended cutting speeds.

5. Using

small machine tools with low horsepower.

8. Define the orthogonal and

oblique cutting.

Orthogonal cutting: The

cutting edge of tool is perpendicular to the work piece axis. Oblique

cutting: The cutting edge is inclined at an acute angle with normal to the

cutting velocity vector is called oblique cutting process.

9. What are the favorable factors

for discontinuous chip formation?

Maching of brittle materials. Small

rake angle

Higher depth of cut Low

cutting speeds

Excess cutting fluid.

Cutting ductile materials with low speed and small rake angle

of the tool.

10. What are the favorable factors

for continuous chip formation?

Small rake angle Low

cutting speed

Strong adhesion between chip and tool face. Coarse feed

Insufficient cutting fluid. Large

uncut thickness.

11. Define machineability of metal.

Machine ability is defined as the

ease with which a material can be satisfactorily machined.

Life of the tool before tool failure or resharpening.

12. What is shear plane?

The material of work piece is

stressed beyond its yield point under the compressive force. This causes the

material to deform plastically and shear off. The plastic floe takes place in a

localized region is called shear plane.

13. What is chip and mention its

different types?

The sheared material begins to

along the cutting tool face in the form of small pieces is called chip. The

chips are mainly classified into three types.

a. Continuous

chip.

b. Discontinuous

chip.

c. Continuous

chip with built up edge.

14. Write the factors

affecting the tool life or Write the Taylor’s tool life equation.

Taylor’s equation VT n

=

C

i. Cutting

speed

ii. Feed and

Depth of cut. iii.Tool Geometry

iv.Tool

material

v. Type of

Cutting Fluid

vi.Work

material

vii.Rigidity

of the Machine tool.

15. Define “Side relief”

and “End relief” angle.

Side relief angle: It is the

angle between the portion of the side flank immediately below the side

cutting edge and a line perpendicular to the base of the tool, and measured at

right angle to the side flank.

End relief angle: It is the

angle between the portion of the end flank immediately below the end

cutting edge and a line perpendicular to the base of the tool, and measured at

right angle to the angle.

16. What are the importance of Nose

Radius?

Nose radius is favorable to long

tool life and good surface finish. A sharp point on the end of a tool is highly

stressed, Short lived and leaves a groove in the path of cut. There is an

improvement in surface finish and permissible cutting speed as nose radius is

increased from zero value.

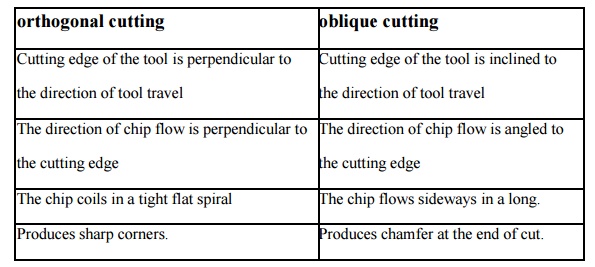

17. What are the differences between orthogonal

cutting and oblique cutting?

orthogonal cutting

Cutting edge of the tool is

perpendicular to the direction of tool travel

The direction of chip flow is

perpendicular to the cutting edge

The chip coils in a tight flat spiral

Produces sharp corners.

oblique cutting

Cutting edge of the tool is inclined

to the direction of tool travel

The direction of chip flow is angled

to the cutting edge

The chip flows sideways in a long.

Produces chamfer at the end of cut.

Related Topics