Chapter: Mechanical : Manufacturing Technology : Theory Of Metal Cutting

Theory of Metal Cutting

THEORY OF METAL CUTTING

Definitions

Machining:

Term applied to all material-removal processes

Metal cutting: The

process in which a thin layer of excess metal (chip) is removed by a wedge-shaped

single-point or multipoint cutting tool with defined geometry from a work

piece, through a process of extensive plastic deformation

MECHANICS OF CHIP FORMATION

The

cutting itself is a process of extensive plastic deformation to form a chip

that is removed afterward. The basic mechanism of chip formation is essentially

the same for all machining operations. Assuming that the cutting action is

continuous, we can develop so-called continuous model of cutting process.

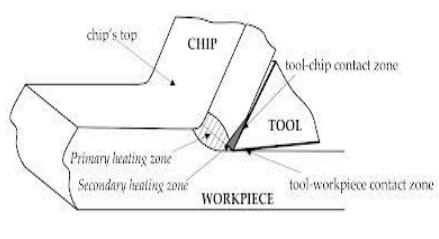

The cutting model shown above is

oversimplified. In reality, chip formation occurs not in a plane but in

so-called primary and secondary shear zones, the first one between the cut and

chip, and the second one along the cutting tool face.

Single-point cutting tool,

As distinguished

from other cutting tools such as a The cutting edge is ground to suit a particular machining operation and

may be re sharpened or reshaped as needed. The ground tool bit is held rigidly

by a tool holder while it is cutting.

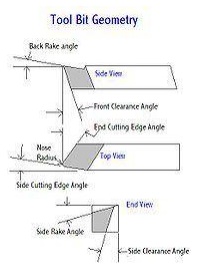

Back Rake is to help control the direction of

the chip, which naturally curves into the work due to the difference in length

from the outer and inner parts of the cut. It also helps counteract the

pressure against the tool from the work by pulling the tool into the work.

Side Rake along with back rake controls the chip flow and partly

counteracts the resistance of the work to the movement of the cutter and can be

optimized to suit the particular material being cut. Brass for example requires

a back and side rake of 0 degrees while aluminum uses a back rake of 35 degrees

and a side rake of 15 degrees. Nose Radius makes the finish of the cut smoother

as it can overlap the previous cut and eliminate the peaks and valleys that a

pointed tool produces. Having a radius also strengthens the tip, a sharp point

being quite fragile.

All the other

angles are for clearance in order that no part of the tool besides the actual

cutting edge can touch the work. The front clearance angle is usually 8 degrees

while the side clearance angle is 10-15 degrees and partly depends on the rate

of feed expected.

Minimum angles

which do the job required are advisable because the tool gets weaker as the

edge gets keener due to the lessening support behind the edge and the reduced

ability to absorb heat generated by cutting.

The Rake angles on

the top of the tool need not be precise in order to cut but to cut efficiently

there will be an optimum angle for back and side rake.

Forces in machining

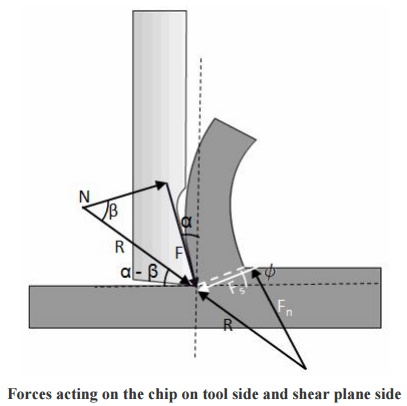

If you make a free body analysis of the chip,

forces acting on the chip would be as follows.

At cutting tool side due to motion of chip against tool there will be a frictional force and a normal force to support that. At material side thickness of the metal increases while it flows from uncut to cut portion. This thickness increase is due to inter planar slip between different metal layers. There should be a shear force (Fs) to support this phenomenon. According to shear plane theory this metal layer slip happens at single plane called shear plane. So shear force acts on shear plane. Angle of shear plane can approximately determined using shear plane theory analysis. It is as follows

Forces acting on the chip on tool side and shear plane side

Shear force on

shear plane can be determined using shear strain rate and properties of

material. A normal force (Fn) is also present perpendicular to shear plane. The

resultant force

(R) at cutting tool

side and metal side should balance each other in order to make the chip in

equilibrium. Direction of resultant force, R is determined as shown in Figure.

Types of chip

There are three types of chips that are commonly produced in

cutting,

Discontinuous chips

Continuous chips

Continuous chips with built up edge

A discontinuous chip comes off as

small chunks or particles. When we get this chip it may indicate,

Brittle work material

Small or negative rake angles

Coarse feeds and low speeds

A continuous chip looks like a

long ribbon with a smooth shining surface. This chip type may indicate,

Ductile work materials

Large positive rake angles

Fine feeds and high speeds

Continuous chips with a built up

edge still look like a long ribbon, but the surface is no longer smooth and

shining. Under some circumstances (low cutting speeds of ~0.5 m/s, small or

negative rake angles),

Work materials like mild steel,

aluminum, cast iron, etc., tend to develop so-called built-up edge, a very

hardened layer of work material attached to the tool face, which tends to act

as a cutting edge itself replacing the real cutting tool edge. The built-up

edge tends to grow until it reaches a critical size (~0.3 mm) and then passes

off with the chip, leaving small fragments on the machining surface. Chip will

break free and cutting forces are smaller, but the effects is a rough machined

surface. The built-up edge disappears at high cutting speeds.

Chip control

Discontinuous chips are generally desired because

They are

less dangerous for the operator

Do not cause damage to workpiece surface and machine tool

Can be easily removed from the work zone

Can be easily handled and disposed after machining.

There are three principle methods to produce the favourable

discontinuous chip:

Proper selection of cutting conditions

Use of

chip breakers

Change in

the work material properties

Chip breaker

Chip break and chip curl may be

promoted by use of a so-called chip breaker. There are two types of chip

breakers

External type, an inclined obstruction clamped to the tool

face

Integral type, a groove ground into the tool face or bulges

formed onto the tool face

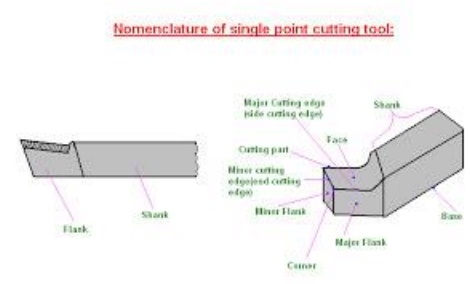

Cutting

tool nomenclature

Back Rake is to help control the

direction of the chip, which naturally curves into the work due to the

difference in length from the outer and inner parts of the cut. It also helps

counteract the pressure against the tool from the work by pulling the tool into

the work.

Side Rake along with back rake

controls the chip flow and partly counteracts the resistance of the work to the

movement of the cutter and can be optimized to suit the particular material

being cut. Brass for example requires a back and side rake of 0 degrees while

aluminum uses a back rake of 35 degrees and a side rake of 15 degrees.

Nose Radius makes the finish of

the cut smoother as it can overlap the previous cut and eliminate the peaks and

valleys that a pointed tool produces. Having a radius also strengthens the tip,

a sharp point being quite fragile.

All the other angles are for

clearance in order that no part of the tool besides the actual cutting edge can

touch the work. The front clearance angle is usually 8 degrees while the side

clearance angle is 10-15 degrees and partly depends on the rate of feed

expected.

Minimum angles which do the job

required are advisable because the tool gets weaker as the edge gets keener due

to the lessening support behind the edge and the reduced ability to absorb heat

generated by cutting.

The Rake

angles on the top of the tool need not be precise in order to cut but to cut

efficiently there will be an optimum angle for back and side rake.

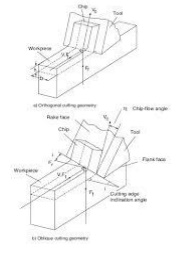

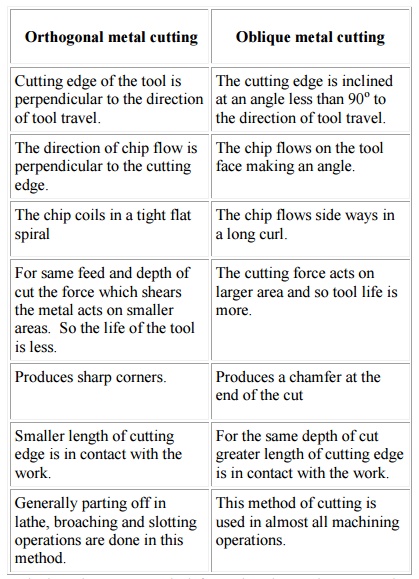

Orthogonal

metal cutting

Orthogonal

metal cutting

Cutting edge of the tool is perpendicular to the

direction of tool travel.

The direction of chip flow is perpendicular to the

cutting edge.

The chip coils in a tight flat spiral

For same feed and depth of cut the force which

shears the metal acts on smaller areas. So the life of the tool is less.

Produces sharp corners.

Smaller length of cutting edge is in contact with

the work.

Generally parting off in lathe, broaching and

slotting operations are done in this method.

Oblique

metal cutting

The cutting edge is inclined at an angle less than

90o to the direction of tool travel.

The chip flows on the tool face making an angle.

The chip flows side ways in a long curl.

The cutting force acts on larger area and so tool

life is more.

Produces a chamfer at the end of the cut

For the same depth of cut greater length of cutting

edge is in contact with the work.

This method of cutting is used in almost all

machining operations.

Depending

on whether the stress and deformation in cutting occur in a plane

(two-dimensional case) or in the space (three-dimensional case), we consider

two principle types of cutting:

Orthogonal cutting the cutting

edge is straight and is set in a position that is perpendicular to the

direction of primary motion. This allows us to deal with stresses and strains

that act in a plane.

Oblique cutting the cutting edge is set at an angle.

According to the number of active

cutting edges engaged in cutting, we distinguish again two types of cutting:

Single-point cutting the cutting tool has only one major

cutting edge

Examples: turning, shaping, boring

Multipoint cutting the cutting tool has more than one major

cutting edge

Examples: drilling, milling,

broaching, reaming. Abrasive machining is by definition a process of multipoint

cutting.

Cutting conditions

Each machining operation is

characterized by cutting conditions, which comprises a set of three elements:

Cutting velocity: The traveling

velocity of the tool relative to the work piece. It is measured in m/s or

m/min.

Depth of cut: The axial

projection of the length of the active cutting tool edge, measured in mm. In

orthogonal cutting it is equal to the actual width of cut.

Feed: The relative movement of

the tool in order to process the entire surface of the work piece. In

orthogonal cutting it is equal to the thickness of cut and is measured in mm.

Thermal aspects

In cutting, nearly all of energy

dissipated in plastic deformation is converted into heat that in turn raises

the temperature in the cutting zone. Since the heat generation is closely

related to the plastic deformation and friction, we can specify three main

sources of heat when cutting,

Plastic deformation by shearing in the primary shear zone

Plastic deformation by shearing and friction on the cutting

face

Friction between chip and tool on the tool flank

Heat is mostly dissipated by,

The discarded chip carries away about 60~80% of the total heat

The

workpiece acts as a heat sink drawing away 10~20% heat

The cutting tool will also draw away ~10% heat

If coolant is used in cutting,

the heat drawn away by the chip can be as big as 90% of the total heat

dissipated. Knowledge of the cutting temperature is important because it:

Affects the wear of the cutting tool.

Cutting temperature is the primary factor affecting the cutting tool wear can

induce thermal damage to the machined surface. High surface temperatures

promote the process of oxidation of the machined surface. The oxidation layer

has worse mechanical properties than the base material, which may result in

shorter service life. Causes dimensional errors in the machined surface. The

cutting tool elongates as a result of the increased temperature, and the

position of the cutting tool edge shifts toward the machined surface, resulting

in a dimensional error of about 0.01~0.02 mm. Since the processes of thermal

generation, dissipation, and solid body thermal deformation are all transient,

some time is required to achieve a steady-state condition

Cutting temperature determination

Cutting temperature is either

measured in the real machining process, or predicted in the machining process

design. The mean temperature along the tool face is measured directly by means

of different thermocouple techniques, or indirectly by measuring the infrared

radiation, or examination of change in the tool material microstructure or

micro hardness induced by temperature. Some recent indirect methods are based

on the examination of the temper color of a chip, and on the use of thermo

sensitive paints.

There are no simple reliable

methods of measuring the temperature field. Therefore, predictive approaches

must be relied on to obtain the mean cutting temperature and temperature field

in the chip, tool and work piece.

For cutting temperature prediction, several approaches are

used:

Analytical methods: there are

several analytical methods to predict the mean temperature. The interested

readers are encouraged to read more specific texts, which present in detail

these methods. Due to the complex nature of the metal cutting process, the

analytical methods are typically restricted to the case of orthogonal cutting.

Numerical methods: These methods

are usually based on the finite element modeling of metal cutting. The

numerical methods, even though more complex than the analytical approaches,

allow for prediction not only of the mean cutting temperature along the tool

face but also the temperature field in orthogonal and oblique cutting.

Cutting tool materials

Requirements

The cutting

tool materials must possess a number of important properties to avoid excessive

wear, fracture failure and high temperatures in cutting, the following

characteristics are essential for cutting materials to withstand the heavy

conditions of the cutting process and to produce high quality and economical

parts:

Hardness at elevated temperatures

(so-called hot hardness) so that hardness and strength of the tool edge are

maintained in high cutting temperatures:

Toughness: ability of the

material to absorb energy without failing. Cutting if often accompanied by

impact forces especially if cutting is interrupted, and cutting tool may fail

very soon if it is not strong enough.

Wear resistance: although there

is a strong correlation between hot hardness and wear resistance, later depends

on more than just hot hardness. Other important characteristics include surface

finish on the tool, chemical inertness of the tool material with respect to the

work material, and thermal conductivity of the tool material, which affects the

maximum value of the cutting temperature at tool-chip interface.

Cutting tool materials

Carbon Steels

It is the oldest of tool

material. The carbon content is 0.6~1.5% with small quantities of silicon,

Chromium, manganese, and vanadium to refine grain size. Maximum hardness is

about HRC 62. This material has low wear resistance and low hot hardness. The

use of these materials now is very limited.

High-speed steel (HSS)

First produced in 1900s. They are

highly alloyed with vanadium, cobalt, molybdenum, tungsten and Chromium added

to increase hot hardness and wear resistance. Can be hardened to various depths

by appropriate heat treating up to cold hardness in the range of HRC 63-65. The

cobalt component give the material a hot hardness value much greater than

carbon steels. The high toughness and good wear resistance make HSS suitable

for all type of cutting tools with complex shapes for relatively low to medium

cutting speeds. The most widely used tool material today for taps, drills,

reamers, gear tools, end cutters, slitting, broaches, etc.

Cemented Carbides

Introduced in the 1930s. These

are the most important tool materials today because of their high hot hardness

and wear resistance. The main disadvantage of cemented carbides is their low

toughness. These materials are produced by powder metallurgy methods, sintering

grains of tungsten carbide (WC) in a cobalt (Co) matrix (it provides

toughness). There may be other carbides in the mixture, such as titanium

carbide (TiC) and/or tantalum carbide (TaC) in addition to WC.

Ceramics

Ceramic materials are composed

primarily of fine-grained, high-purity aluminum oxide (Al2O3), pressed and

sintered with no binder. Two types are available:

White, or cold-pressed ceramics,

which consists of only Al2O3 cold pressed into inserts and sintered at high

temperature.

Black, or hot-pressed ceramics,

commonly known as cermets (from ceramics and metal). This material consists of

70% Al2O3 and 30% TiC. Both materials have very high wear resistance but low

toughness; therefore they are suitable only for continuous operations such as

finishing turning of cast iron and steel at very high speeds. There is no

occurrence of built-up edge, and coolants are not required.

Cubic boron nitride (CBN) and synthetic diamonds

Diamond is the hardest substance

ever known of all materials. It is used as a coating material in its

polycrystalline form, or as a single-crystal diamond tool for special

applications, such as mirror finishing of non-ferrous materials. Next to

diamond, CBN is the hardest tool material. CBN is used mainly as coating

material because it is very brittle. In spite of diamond, CBN is suitable for

cutting ferrous materials.

Tool wear and tool life

The life of a cutting tool can be

terminated by a number of means, although they fall broadly into two main

categories:

Gradual wearing of certain

regions of the face and flank of the cutting tool, and abrupt tool failure.

Considering the more desirable case Πthe life of a cutting tool is therefore

determined by the amount of wear that has occurred on the tool profile and

which reduces the efficiency of cutting to an unacceptable level, or eventually

causes tool failure. When the tool wear reaches an initially accepted amount,

there are two options,

To resharpen the tool on a tool grinder, or

To replace the tool with a new one.

This second possibility applies in two cases,

When the resource for tool resharpening is exhausted. or

The tool does not allow for resharpening, e.g. in case of the

indexable carbide inserts

Wear zones

Gradual wear occurs at three

principal locations on a cutting tool. Accordingly, three main types of tool

wear can be distinguished,

Crater wear

Flank wear

Corner wear

Crater wear: consists of a

concave section on the tool face formed by the action of the chip sliding on

the surface. Crater wear affects the mechanics of the process increasing the

actual rake angle of the cutting tool and consequently, making cutting easier.

At the same time, the crater wear weakens the tool wedge and increases the

possibility for tool breakage. In general, crater wear is of a relatively small

concern.

Flank

wear: occurs on the tool flank as a result of friction between the machined

surface of the workpiece and the tool flank. Flank wear appears in the form of

so-called wear land and is measured by the width of this wear land, VB, Flank

wear affects to the great extend the mechanics of cutting. Cutting forces

increase significantly with flank wear. If the amount of flank wear exceeds

some critical value (VB > 0.5~0.6 mm), the excessive cutting force may cause

tool failure.

Corner wear: occurs on the tool

corner. Can be considered as a part of the wear land and respectively flank

wear since there is no distinguished boundary between the corner wear and flank

wear land. We consider corner wear as a separate wear type because of its

importance for the precision of machining. Corner wear actually shortens the

cutting tool thus increasing gradually the dimension of machined surface and

introducing a significant dimensional error in machining, which can reach

values of about 0.03~0.05 mm.

Tool life

Tool wear is a time dependent

process. As cutting proceeds, the amount of tool wear increases gradually. But

tool wear must not be allowed to go beyond a certain limit in order to avoid

tool failure. The most important wear type from the process point of view is

the flank wear, therefore the parameter which has to be controlled is the width

of flank wear land, VB. This parameter must not exceed an initially set safe

limit, which is about 0.4 mm for carbide cutting tools. The safe limit is

referred to as allowable wear land (wear criterion),

. The cutting time required for

the cutting tool to develop a flank wear land of width is called tool life, T,

a fundamental parameter in machining. The general relationship of VB versus

cutting time is shown in the figure (so-called wear curve). Although the wear

curve shown is for flank wear, a similar relationship occurs for other wear

types. The figure shows also how to define the tool life T for a given wear

criterion VBk

Parameters, which affect the rate of tool wear, are

Cutting conditions (cutting speed V, feed f, depth of cut d)

Cutting tool geometry (tool orthogonal rake angle)

Properties of work material

Surface finish

The machining processes generate

a wide variety of surface textures. Surface texture consists of the repetitive

and/or random deviations from the ideal smooth surface. These deviations are

Roughness: small, finely spaced surface irregularities (micro

irregularities)

Waviness: surface irregularities of grater spacing (macro

irregularities)

Lay: predominant direction of surface texture

Three main factors make the surface roughness the most

important of these parameters:

Fatigue life: the service life of

a component under cyclic stress (fatigue life) is much shorter if the surface

roughness is high

Bearing

properties: a perfectly smooth surface is not a good bearing because it cannot

maintain a lubricating film.

Wear: high surface roughness will result in more intensive

surface wear in friction.

Surface finish is evaluated quantitatively by the average

roughness height, Ra

Roughness control

Factors, influencing surface roughness in machining are

Tool geometry (major cutting edge angle and tool corner

radius),

Cutting conditions (cutting velocity and feed), and

Work material properties (hardness).

The influence of the other process parameters is outlined

below:

Increasing the tool rake angle generally improves surface

finish

Higher work material hardness results in better surface finish

Tool material has minor effect on surface finish.

Cutting fluids affect the surface

finish changing cutting temperature and as a result the built-up edge

formation.

Cutting fluids

Cutting fluid (coolant) is any

liquid or gas that is applied to the chip and/or cutting tool to improve

cutting performance. A very few cutting operations are performed dry, i.e.,

without the application of cutting fluids. Generally, it is essential that

cutting fluids be applied to all machining operations.

Cutting fluids serve three principle functions:

To remove heat in cutting: the

effective cooling action of the cutting fluid depends on the method of

application, type of the cutting fluid, the fluid flow rate and pressure. The

most effective cooling is provided by mist application combined with flooding.

Application of fluids to the tool flank, especially under pressure, ensures

better cooling that typical application to the chip but is less convenient.

To lubricate the chip-tool

interface: cutting fluids penetrate the tool-chip interface improving

lubrication between the chip and tool and reducing the friction forces and

temperatures.

To wash away chips: this action

is applicable to small, discontinuous chips only. Special devices are

subsequently needed to separate chips from cutting fluids.

Methods of application

Manual

application

Application of a fluid from a can

manually by the operator. It is not acceptable even in job-shop situations

except for tapping and some other operations where cutting speeds are very low

and friction is a problem. In this case, cutting fluids are used as lubricants.

Flooding

In flooding, a steady stream of

fluid is directed at the chip or tool-workpiece interface. Most machine tools

are equipped with a recirculating system that incorporates filters for cleaning

of cutting fluids. Cutting fluids are applied to the chip although better

cooling is obtained by applying it to the flank face under pressure

Coolant-fed tooling

Some tools, especially drills for

deep drilling, are provided with axial holes through the body of the tool so

that the cutting fluid can be pumped directly to the tool cutting edge.

Mist applications

Fluid droplets suspended in air

provide effective cooling by evaporation of the fluid. Mist application in

general is not as effective as flooding, but can deliver cutting fluid to

inaccessible areas that cannot be reached by conventional flooding.

Types of cutting fluid

Cutting Oils

Cutting oils are cutting fluids

based on mineral or fatty oil mixtures. Chemical additives like sulphur improve

oil lubricant capabilities. Areas of application depend on the properties of

the particular oil but commonly, cutting oils are used for heavy cutting

operations on tough steels.

Soluble Oils

The most common, cheap and

effective form of cutting fluids consisting of oil droplets suspended in water

in a typical ratio water to oil 30:1. Emulsifying agents are also added to

promote stability of emulsion. For heavy-duty work, extreme pressure additives

are used. Oil emulsions are typically used for aluminum and cooper alloys.

Chemical fluids

These cutting fluids consist of

chemical diluted in water. They possess good flushing and cooling abilities.

Tend to form more stable emulsions but may have harmful effects to the skin.

Environmental issues

Cutting fluids become

contaminated with garbage, small chips, bacteria, etc., over time. Alternative

ways of dealing with the problem of contamination are:

Replace the cutting fluid at least twice per month,

Machine

without cutting fluids (dry cutting),

Use a filtration system to continuously clean the cutting

fluid.

Disposed cutting fluids must be

collected and reclaimed. There are a number of methods of reclaiming cutting

fluids removed from working area. Systems used range from simple settlement

tanks to complex filtration and purification systems. Chips are emptied from

the skips into a pulverizer and progress to centrifugal separators to become a

scrap material. Neat oil after separation can be processed and returned, after

cleaning and sterilizing to destroy bacteria.

Machinability

Machinability is a term

indicating how the work material responds to the cutting process. In the most

general case good machinability means that material is cut with good surface

finish, long tool life, low force and power requirements, and low cost.

Machinability of different materials

Steels Leaded steels: lead acts

as a solid lubricant in cutting to improve considerably machinability.

Resulphurized steels: sulphur

forms inclusions that act as stress raisers in the chip formation zone thus

increasing machinability.

Difficult-to-cut steels: a group

of steels of low machinability, such as stainless steels, high manganese

steels, precipitation-hardening steels.

Other metals

Aluminum: easy-to-cut material

except for some cast aluminum alloys with silicon content that may be abrasive.

Cast iron: gray cast iron is

generally easy-to-cut material, but some modifications and alloys are abrasive

or very hard and may cause various problems in cutting.

Cooper-based alloys: easy to

machine metals. Bronzes are more difficult to machine than brass.

Selection of cutting conditions

For each machining operation, a

proper set of cutting conditions must be selected during the process planning.

Decision must be made about all three elements of cutting conditions,

Depth of cut

Feed

Cutting speed

There are two types of machining operations:

Roughing

operations: the primary objective of any roughing operation is to remove as

much as possible material from the work piece for as short as possible

machining time. In roughing operation, quality of machining is of a minor

concern.

Finishing

operations: the purpose of a finishing operation is to achieve the final shape,

dimensional precision, and surface finish of the machined part. Here, the

quality is of major importance. Selection of cutting conditions is made with

respect to the type of machining operation. Cutting conditions should be

decided in the order depth of cut - feed - cutting speed.

Related Topics