Chapter: Mechanical : Computer Aided Design : Assembly of Parts

Important Questions and Answers: Assembly of Parts

ASSEMBLY OF PARTS

1. Define

Assembly modeling.

Assembly modeling is defined as a

technology and method used by computer-aided design and product visualization

computer software systems to handle multiple files that represent components

within a product. The components within an assembly are represented as solid or

surface models.

2. Write

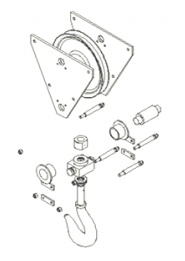

short note on Exploded view.

An exploded view consists of

series of steps. One can create steps by selecting and dragging parts in

graphical area.

Example – Exploded view of Assembly of Pulley block

3. List

Features of Bottom-up assembly approach.

•

Allows the designer to use part drawings that

already exist (off the shelf)

•

Provides the designer with more control over

individual parts

•

Multiple copies (instances) of parts can be

inserted into the assembly

4.

List Features of Top-down assembly approach.

•

The approach is ideal for large assemblies

consisting of thousands of parts.

•

The approach is used to deal with large designs

including multiple design teams.

•

It lends itself well to the conceptual design

phase

•

E.g. :

▫

Piping and fittings

▫

Welds

▫

Lock pins

5.

List advanced Mating conditions in assembling

modeling.

6. Applications

of Assembly Models Interference checking Visualization

•

Rendered

•

Exploded

•

Animation

•

Mechanism analysis

7.

Assembly sequence affects

•

difficulty of assembly steps

•

need for fixture

•

potential for parts damage during assembly and

part mating

•

ability to do in-process testing

•

occurrence of the need for reworking

•

time of assembly

•

assembly skill level

•

unit cost of assembly

8.

Interference fit

•

Fits is clearance fit

•

tight fits is interference fit

•

Coplanar: two normal vectors are parallel

•

‘Coplanar’ complements ‘against’

9.

Sketch the Precedence Diagram.

• Designed

to show all the possible assembly sequences of a product.

• Each

individual assembly operation is assigned a number.

• Diagram

is usually organized into columns

10. What are

the three terms used in limit system?

1. Tolerance: Deviation from a basic value

is defined as Tolerance. It can be obtained by taking the difference

between the maximum and minimum permissible limits.

2. Limits: Two extreme permissible sizes

between which the actual size is contained are defined as limits.

3. Deviation: The algebraic difference

between a size and its corresponding basic size. There are two types of

deviations: 1) Upper deviation 2) Lower deviation

11. Write

short note on Tolerances.

Due to human errors, machine settings, etc., it is

nearly impossible to manufacture an absolute dimension as specified by the

designer. Deviation in dimensions from the basic value always arises. This

deviation of dimensions from the basic value is known as Tolerance.

12. Define Clearance fit.

Clearance fit is defined as a

clearance between mating parts. In clearance fit, there is always a positive

clearance between the hole and shaft.

13. Why Transition fit occurs?

Transition fit may result in either

an interference or clearance, depending upon the actual values of the tolerance

of individual parts.

14. When Interference fit is obtained?

Interference fit is

obtained if the difference between the hole and shaft sizes is negative before assembly. Interference fit generally

ranges from minimum to maximum interference. The two extreme cases of

interference are as follows:

15. What is called

Minimum interference?

The magnitude of the difference

(negative) between the maximum size of the hole and the minimum size of the shaft in an interference fit before assembly.

Related Topics