Chapter: Mechanical : Computer Aided Design : Assembly of Parts

Assembly modeling

Assembly modeling

Assembly modeling is a technique applied

by CAD and product visualization software systems to utilize multiple files

that shows components within a product. The components within an assembly are

called as solid / surface models.

The designer usually

has approach to models that others are functioning on concurrently. For

example, different people may be creating one machine that has different

components. New parts are extra to an assembly model as they are generated.

Every designer has approach to the assembly model, during a work in progress,

and while working in their own components. The design development is noticeable

to everyone participated. Based on the system, it might be essential for the

users to obtain the most recent versions saved of every individual component to

update the assembly.

The personal data files

defining the 3D geometry of personal components are assembled together via a

number of sub assembly levels to generate an assembly explaining the complete

product. Every CAD methods support the bottom-up construction. A few systems,

through associative copying of geometry between components allow top-down

construction. Components can be situated within the assembly applying absolute

coordinate position methods.

Mating conditions are

defines of the relative location of mechanism between each other; for example

axis position of two holes or distance between two faces. The final place of

all objects based on these relationships is computing using a geometry

constraint engine built into the CAD package.

The significance of

assembly modeling in obtaining the full advantages of Product Life-cycle

Management has directed to ongoing benefits in this technology. These contain

the benefit of lightweight data structures that accept visualization of and

interaction with huge amounts of data related to product, interface between PDM

systems and active digital mock up method that combine the skill to visualize the

assembly mock up with the skill to design and redesign with measure, analyze

and simulate.

1. Assembly Concepts

When components are

additional to an assembly, parent and child relationships are created. These

relationships are displayed by graphically as an assembly tree. Parts are

parametrically connected by position constraints. These constraints have data

about how a part should be placed within the assembly hierarchy and how it

should respond if other components are edited.

Functioning within the

framework of an assembly is prepared easier by accepting to apply more commands

to other parts and sub-assemblies. These contain the Annotation Text, Inquire,

Point, Datum Plane and Pattern Component commands. Bigger assembly performance

is improved by removing unwanted redraws and improved display management while

zooming.

Assembly

models have additional data than simply the sum of their components. With

assembly modeling interference verifies between parts and assembly specific

data such as mass properties.

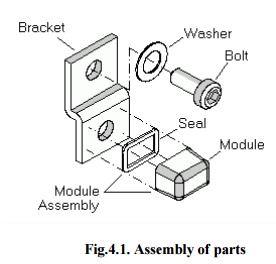

Fig.4.1.

Assembly of parts

2. Bottom up Assembly design

In a ‘bottom

up’assembly design, complex assemblies are divided into minor subassemblies and

parts. Every part is considered as individual part by one or more designers.

The parts can be archived in a library in one or more 3D Files. This is

the high effective way to generate and manage

complex assemblies.

Every part is included

into the active part making a component request and thus an assembly. The

component will be the child of the active part and then it will be the active

part. Hence an instance

of the actual part is applied; it revises

automatically if the archived part is edited by activating.

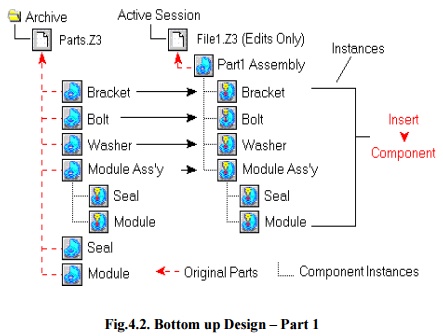

Bottom up Hierarchy:

The ‘bottom up’assembly

design hierarchy of the basic assembly is shown in figure 4.2. All the parts

exist prior to Part1. When Part1 is generated, it becomes the

active. It would utilize the menu

sequence to add Bracket and it becomes the

active part.

Insert

> Component

Or

Assembly

Design Tool Bar >

As

per example shown in figure 4.2., ‘Bracket’is a child of

Part1. The dashed line represents that

‘Bracket’exists in the 3D file

Parts Z3. The dotted line represents

that ‘Bracket’is inserted into Part-1.

After Bracket is added, Part1 is

redefined. Bolt and Washer are then added

the same process and Part-1 is reactivated

again.

Fig.4.2.

Bottom up Design –Part 1

Module

of subassembly is added similar as ‘Bracket’,‘Bolt’,and

‘Washer’again becoming a

child of Part-1. But, because Module

Subassembly already has the two items Seal and Module, they

are added and continue as its children.

Sequence

of operations (Fig. 4.2.):

§ File-1

has

1 part.

§ Part-1

has

4 components.

§ Module

Subassembly has 2 components.

§ All

of the items are illustrations of the original parts that reside in the ZW3D

file Parts Z3.

§ If

File-1 is eliminated from the active assembly before it is saved and Part1

are removed. The original parts placed in the file Parts Z3 are not

changed.

§ If

File-1 is saved and Part1 is also saved.

§ If

File-1 is erased and Part1 is also erased.

3.Top down Assembly Design

In a ‘topdown’assembly design all parts

are classically designed by the similar person within a single part. 3D

assembly handles ‘top down’method by allowing to design and creation of

a component while work in the active part. Hence, the active part will be an

assembly part.

The part becomes a child of the active part and then

it will be the active part. The part, when generated, is an instance of a base

part which will be a root object located in the active file. Every part is

activated and modified as needed. The ‘top down’assembly design has its

benefits. If the project is terminated or to go in a different new direction,

removing the file will remove the part and all of its components.

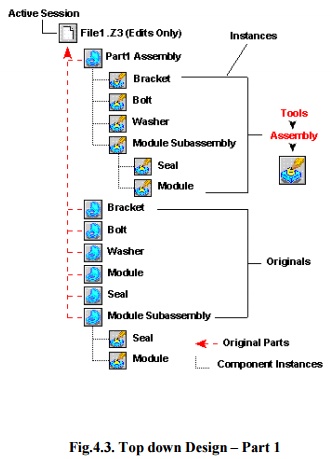

Top down Hierarchy

The ‘top down’assembly

method is shown in a figure 4.3 and one of the components exist prior to Part-1.

When Part-1 is generated, it will be the active part. The following

command sequence to generate Bracket and create it the active part.

Assembly

Design Tool Bar >

Fig.4.3.

Top down Design –Part 1

Bracket is

a child of Part-1. The dashed line illustrates that by default when

Bracket is generated; it is attached to File-1. The dotted

line illustrates that Bracket is attached into Part-1. When Bracket

is executed Part1 is reactivated. Bolt and Washer

are then generated using the similar process and Part-1 is reactivated

again.

Subassembly

Module is generated like the Bracket, Bolt, and

Washer again will be a child of Part1. But, Module

Subassembly remains active when seal is developed. Seal will be the

active part and by default also exists in File-1 but is inserted into Module

Subassembly hence it was active at the time of seal was created.

Subassembly Module is then reactivated and Module

is generated like

a

Seal.

Sequence

of operations (Fig 4.3):

· File-1

has 7.

· Part-1

contains 4 components, which are illustrations of the basic parts located in

File-1.

·

Subassembly Module contains 2 components

which are also illustrations of the basic parts located in File-1.

· If

File-1 is saved it has all of its original parts.

· If

File-1 is erased, it and all of its basic parts are erased.

Related Topics