Chapter: Mechanical : Computer Aided Design : Assembly of Parts

Interference of position and orientation

Interference of

position and orientation

Designers and manufacturers should check

jointly that a provided product can be assembled, without interference between

parts, before the product to be manufactured. Similarly, all the CAD tools

presently have the potential to directly analyze the possibility of a specified

assembly plan for a product.

An assessment of previous assembly

sequence and optimization research explains that most previous assembly

planners apply either feature-mating or interference-free techniques to find

assembly part interference interaction. In both feature-mating and

interference-free techniques focused upon the basic geometrical data and

restrictions for the designed product, which are generally contained in

connected CAD files.

When completely automate the procedure

of creating a professional assembly plan, geometrical information for CAD

models should be automatically taken from CAD files, analyzed for interference

relationships between components in the assembly, and then designed for

utilized the assembly analysis tools. Most of the previous assembly sequence

planners do not have the potential to complete the three tasks; they need users

to manually input part attributes or interference data, which is so

time-consuming.

Determining

Interference Relationships between Parts

In automated assembly

schemes, most parts are assembled along with the principal axis. Hence, to fine

interference between parts while assembly, the projected technique referred six

assembly directions along with the principal assembly axis: +x, -x,

+y, -y, +z, and -z. But, the method could be

improved, to think other assembly directions, as required. The projected system

uses projection of part coordinates onto planes in three principal axis (x,

y ,z) to find the obstruction between parts sliding along some of

the six principal assembly axis. The projections overlap between any two parts

in a specified axis direction shows a potential interference between the two

parts, when one of the two parts slides along the specified direction, with

respect to the other. Vertex coordinates for overlapped projections are then

evaluated to find if real collisions would happen between parts with overlapped

projections. The planned process stores the determined interference data for

allocated assembly direction in a group of interference free matrices, for

compatibility with previous planners of assembly.

The swept volume

interference and the multiple interference detection systems are appropriate

for three-dimensional interference determination between B-REP entities. But,

both techniques were developed for real-time interference detection between two

moving parts in a simulation environment. As a result, these two techniques are

expensive in computationally. For the assembly planning issue, actual collision

finding capacity along subjective relative motion vectors is not require.

Instead, a efficient computational technique is required for finding if two

parts will collide when they are assembled in a specified order along any one

of the six principle assembly axis.

Interference-free matrix

An interference-free

matrix shows interference between two components, when one component is moved,

in a given assembly direction, into an assembled location, with another

component already in an assembled location. Assembly actions that result in

interferences are denoted as ‘0’in the matrix, and assembly actions that do not

result in interferences are denoted as ‘1’in the matrix.

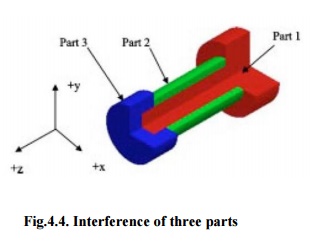

As

shown in figure 4.4., the interference-free matrix of an assembly having three

parts, for assembly movement sliding from infinity of negative toward infinity

of positive along the +x direction is as follows:

Fig.4.4.

Interference of three parts

Interference-free

matrix for sliding in the +x direction:

The row in the

Interference-free matrix indicate the components being shifted during a given

assembly operation, and the column indicate the parts that have previously been

assembled. Hence, since matrix element (2, 1) is equal to ‘0’,if Part-1 is

assembled initially, and after that Part-2 is assembled in the direction of +x,

Part-2 will collide with Part-1. Similarly, matrix element (1, 2) is equal to

‘1’,if Part-2 is assembled initially, and then Part-1 is assembled in the

direction of +x, Part-1 will not collide with Part-2. As a part cannot

be assembled after itself, all elements in the diagonal matrix are set to

‘0’.As a whole, six matrices are utilized to show interference relationships

between parts in the six principal axes. When robotically creating

interference-free matrices, the projected algorithm finds matrix elements row

by row. When two parts would interfere through assembly in a given direction,

the program inserts a ‘0’in the corresponding matrix position; or inserts as a

‘1’.

Related Topics