Chapter: Mechanical : Computer Aided Design : Assembly of Parts

Tolerance Analysis

Tolerance Analysis

Tolerance analysis is a

title to a different approaches applied in product design to know how

deficiencies in parts as they are manufactured, and in assemblies, influence

the ability of a product to meet customer needs. Tolerance analysis is a way of

accepting how basis of deviation in part dimensions and assembly constraints

distribute across parts and assemblies, and how that total deviation affects

the ability of a drawing to reach its design necessities within the process

capabilities of organizations and supply chains.

Tolerance openly

affects the cost and performance of products. In electrical machines, safety

needs that the power supply to be situated a minimum gap from adjacent

components, such as one more sheet-metal component, in order to remove

electrical short circuits. Tolerance analysis will describe whether the small

clearances specified will meet the safety requirement, assigned manufacturing

and assembly variability force on the minimum clearance.

1. Tolerance stack-up

Tolerance stack-up

computations show the collective effect of part tolerance with respect to an

assembly need. The tolerances ‘stacking wouldup’describe to adding tolerances

to obtain total part tolerance, then evaluating that to the existing gap in

order to see if the design will work suitably. This simple evaluation is also

defined as ‘worst case analyses’.Worst case analysis is suitable for definite

needs where failure would signify failure for a company. It is also needful and

suitable for problems that occupy a low number of parts. Worst case analysis is

always carried out in a single direction that is a 1-D analysis. If the

analysis has part dimensions that are not parallel to the assembly measurement

being defined, the stack-up approach must be edited since 2D variation such as

angles, or any variation that is not parallel with the 1-D direction, does not

influence the measurement of assembly with a 1-to-1 ratio.

The tolerance stacking

issue occurs in the perception of assemblies from interchangeable parts because

of the inability to create or join parts accurately according to nominal.

Either the applicable part dimension changes around various nominal value from

part by part or it is the act of assembly that directs to variation. For

example, as two parts are combined through matching holes pair there is not

only variation in the location of the holes relative to nominal centers on the

parts but also the slippage difference of matching holes relative to each other

when safe.

Thus there is the

opportunity that the assembly of such interacting parts will not move or won’t

come closer as planned. This can generally be judged by different assembly

criteria, say G1, G2,... Here we will be discussed with just one assembly

criterion, say G, which can be noted as a function of the part dimensions

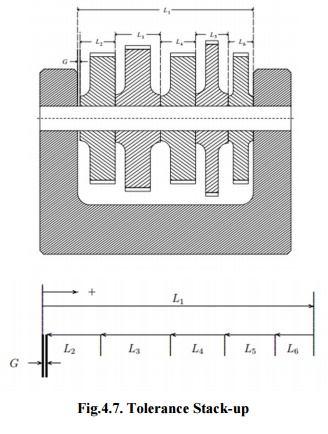

L1,...,Ln. A example is shown in Figure 4.7., where n = 6 and is the clearance

gap of interest. It finds whether the stack of cogwheels will locate within the

case or not. Thus it is preferred to have G > 0, but for performance of

functional causes one may also require to limit G.

G

= L1(2 +−L3 + L4 + L5 + L6)

=

L1 −− L2L3− L45 −− L6

Fig.4.7.

Tolerance Stack-up

As per the example, the

required lengths ‘Li ‘may vary from the nominal lengths ‘λi’by a small value.

If there is higher variation in the ‘Li’there may well be important problems in

accepting G > 0. Thus it is sensible to limit these changes via tolerances.

For similar tolerances, ‘Ti’,represent an ‘upper limit’on the absolute

variation between actual and nominal values of the i th detail part dimension,

it is means that |Li −λi|≤Ti. It is mostly in the interpretation of this last

inequality that the different methods of tolerance stacking vary.

The nominal value ‘γ’of

G is typically computed by replacing in equation L1 −L2 −L3 −L4 − L5 −L6, the

actual values of Li’sby the corresponding nominal values of λi,that is γ= λ1

−λ2 −λ3 −

λ4 λ5− λ−6.

2. Statistical method for tolerance

analysis (RSS) :

In RSS method,

tolerance stacking a significant new element is added to the assumptions, specifically

which the detail differences from nominal are random and independent from part

by part. It is expensive in the sense that it frequently commanded very close

tolerances. That all variations from nominal should dispose themselves in worst

case method to defer the higher assembly tolerance is a relatively unlikely

proposition. On the other hand, it had the advantage of assurance the resulting

assembly tolerance. Statistical tolerance in its typical form operates under

two basic hypotheses:

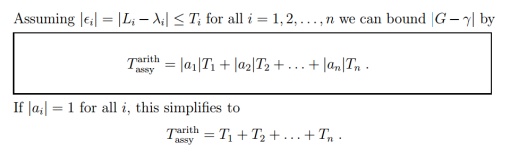

As

per Centered Normal Distribution, somewhat considering that the ‘Li’can occur

anywhere within the tolerance distribution [λi−Ti, λi + Ti], assume that the

‘Li’are normal random variables, that is change randomly according to a normal

distribution, centered on that similar interval and with a ±3σ distribute equal

to the span of that interval, hence 99.73% of all ‘Li’values occur within this

gap. As per the normal distribution is such that the ‘Li’fall with upper

frequency in the middle near ‘λi’and with low frequency closer the interval

endpoints. The match of the ±3σdistribution with the span of the detail

tolerance span is hypothetical to state that almost all parts will satisfy the

detail tolerance limits as shown in figure 4.8.

Fig.4.8.

Centered Normal Distribution

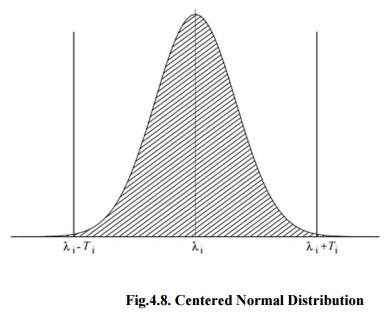

Statistical

tolerance stacking formula is given below:

Where,

ai = ±1 for all i = 1,...,n.

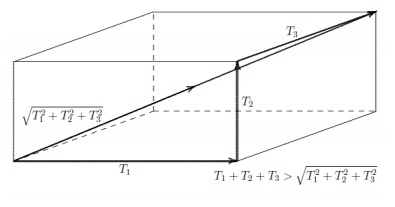

Fig.4.9.

RSS cube

Typically Tstat

assy is considerably smaller than T arith assy. For n=3, the scale

of this variation is simply visualized and valued by a rectangular box with

side lengths T1, T2 and T3. To obtain from one corner of the box to the

diagonally opposite corner, one can cross the gap T21 + T22 + T23 along that

diagonal and follow the three edges with lengths T1,

T2, and T3 for a total length T arith assy = T1 + T2 + T3 as shown in figure

4.9.

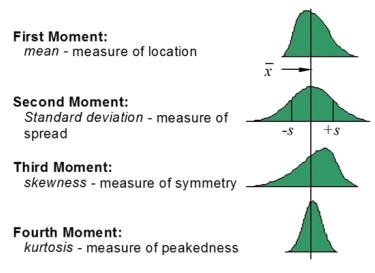

3. Second Order Tolerance Analysis

Due to the manufacturing methods changing for

various types of components, the distribution moments vary as well. RSS only

applies standard deviation and does not contain the upper moments of skewness

and kurtosis that describe the effects tool wear, form aging and other

classical manufacturing situations. Second Order Tolerance Analysis includes

all types of distribution moments as shown in figure 4.9

Fig.4.9.

Second order Tolerance Analysis

Second Order Tolerance Analysis is

required to find what output is going to be when the assembly function is not

linear. In classical mechanical engineering developments kinematic changes and

other assembly performances result in non-linear assembly operations. Second

order estimates are more complex so manual calculations are not suitable but

the computation is greatly improved and becomes feasible within tolerance

analysis software.

4.

Importance of Tolerance Analysis

With smaller product lifecycles, quicker

to market, and higher cost pressures, the uniqueness that distinguishes a

product from its competitors. Engineers are moving to the next order of

resolution in order to improve cycle time and quality and to reduce costs. They

are showing nearer at why they did not get the correct part and assembly

dimension values they needed from manufacturing and then are trying to optimize

the tolerances on the following version of the product. Optimization of

tolerance during design has a high impact on the output of manufacturing, and

better yields direct impact on product cost and quality. Tolerance Analysis

before trying to manufacture a product helps engineers avoid time taking

iterations later in the design cycle.

The electronics industry is attaining

customer satisfaction purposes via a physical shrinking of their components

while adding more capabilities. As electronic devices high densely packaged,

the significance increases to more accurately understanding the interaction of

manufacturing variation and tolerances in design. Similarly, in the aircraft,

automotive and medical device productions, liability costs are increasing while

environmental needs are being more forcefully forced such that companies

requires to understand high precisely what may reason a failure.

Advantages

of Tolerance Analysis

1.

Accurate part assembly.

2.

Elimination of assembly rework

3.

Improvement in assembly quality.

4.

Reduction of assembly cost.

5.

High customer satisfaction.

6. Effectiveness

of out-sourcing.

Limitations

of Tolerance Analysis

1.

Time consuming process.

2.

Skill require for complex assemblies.

Related Topics