Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Numerical Control

Direct Numerical Control

DNC

Historical

Note 6.2 describes several ways in which digital computers have been used to

implement NC In this section, we discuss two of these implementations that are

distinguished from CNC: (1) direct NC and (2) distrihuted.\lC

DNC:

Direct Numerical Control

Distributed Numerical Control

Direct Numerical

Control

The first

attempt 10 use a digitulcuutputer to drive the NC machine tool was DNC This was

in the late 19605 before the advent of CNC. A; initially implemented. DNC

involved the control or a number of machine tools hy a single (mainframe)

computer through direct connection and in real time. Instead of using a punched

tape reader to enter the part program into the Mev, the program was transmitted to the MCU directly from the computer, one

block of instructions at a time. This mode of operation was referred 10 by the

name behind the tape reader (BTR).

The ONe computer provided instruction blocks to the machine tool on demand;

when a machine needed control commands, they were communicated to it

immediately. As each block was executed by the machine, the next block was

transmitted. As far as the machine tool was concerned, the operation was no

different from that of a conventional NC controller. In theory, DNC relieved

the NC system of its least reliable components: the punched tape and tape

reader.

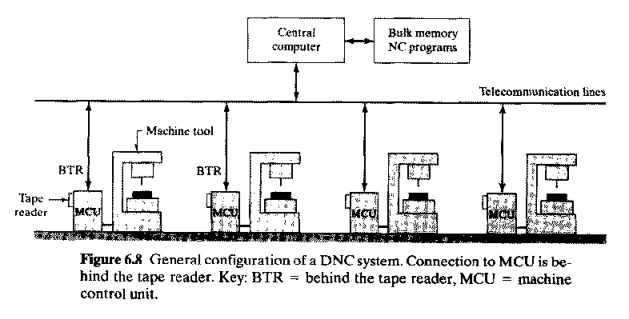

The

general configuration of a ONe system

is depicted in Figure 6.8. The system consisted of four components: (1) central

computer, (2) bulk memory at the central computer site, (3) set of controlled

machines, and (4) telecommunications lines to connect the machines to the

central computer. In operation, the computer caned the required part program

from bulk memory and sent it (one block at a time) to the designated machine

tool. This procedure was replicated for all machine toots under direct control

of the computer.

One

commercially available ONC system during the 1970s claimed to be capable of

controlling up to 256 machines.

In

addition to transmitting data to the machines, the central computer also

received data back from the machines to indicate operating performance in the

shop (e.g., number of mac!Jil1illg ,,;ydcscompleted.uiaclune utilization, and

breakdowns). ThU5, a central ob

jective

of ONe was to achieve twoway communication between the machines and the central

computer.

Advantages

claimed for DNC in the early 19708 included: (1) high reliability of a central

computer compared with individual hardwired MCUs; (2) elimination of the tape and

tape reader, which were unreliable and errorprone; (3) control of multiple

machines by one cornputer;(4) improved computational capability for circular

interpolation; (5) part programs stored magnetically in bulk memory in a

central location; and (6) computer located in an environmentally agreeable

location. However, these advantages were not enough to persuade a conservative

manufacturing community to pay the high investment cost for a ONC system, and

some of the claimed advantages proved to be overly optimistic.

For

example, elimination of tape readers was unrealistic because of the need for an

alternative way to load part programs in case the central computer went down.

The installations of DNC were

limited lathe aerospace industry. which had been involved in N(' technology

since the beginning and possessed a larger

number of NC machines. The.s~ machines were often dispersed throughout

large factories, and DNC

represented an efficient way to distribute part programs to the machines

Distributed

Numerical Control

As the

number of CNC machine installations grew during the 1970s and 19805, DNe emerged once again, but in the i,orm o.f a distributed computer system,

or distributed mencal control (ONe). The configuration of the new DNC is very

SImilar to that shown In Figure 6.8

except that the central computer is connected to MCUs, which are themselves

computers. This permits complete part programs to be sent to the machine tools.

rather than one block at a time. It also permits easier and less costly

installation of the overall system, because the individual CNC machines can be

put into service and the distributed I\'C can be added later. Redundant

computers improve system reliability compared with the original ONe. The new

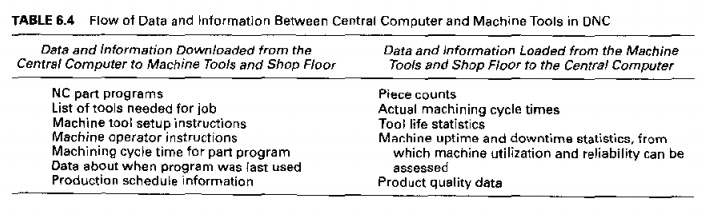

ONe permits twoway communication of data between the shop

floor and

the central computer. which was one of the important features included in the

old ONe. However. improvements in data collection devices as well as advances

in computer

and

communications technologies have expanded the range and flexibility of the

information that can be gathered and disseminated. Some of the data and

information sets included in the twoway communication flow are itemized in

Table

6.4. This

flow of information in DNC is similar to the information flow in shop floor

control, discussed in Chapter 26.

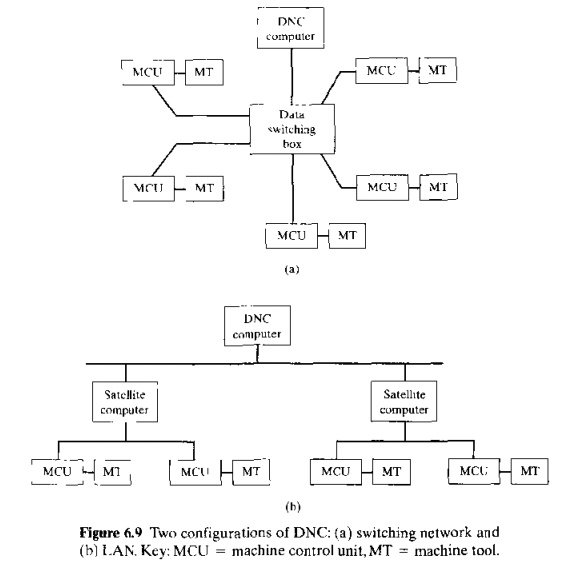

Distributed

NC systems can take on a variety of physical configurations, depending on the

number of machine tools included, job complexity, security requirements, and

equipment availability and preferences. There are several ways to configure a

ONC system. We illustrate two types in Figure 6.9: (a) switching network and

(bl LAN. Each type has several possibte variations.

Thc5wiIChing network is the

simplest DNCsyslem to configure. It uses a data switching box to make a

connection from the central computer to a given CNC machine for downloading

part programs or uploading data. Transrrnssion of programs to the MCU is

accomplished through a RS232C connection, (Virtually all commercial MCUs include

the RS232C or compatible device as standard equipment today.) Use ora switching

box limits the number of machines that can be included in the ONC system. The

limit depends on

factors

such as part program complexity, frequency of service required to each

machine.and capabilities of the central computer. The number of machines in the

ONe system can be increased by

employing a serial link RS232C multiplexer.

Local

area networks have been used for ONe since

the early I980s. Various network structures are used m ONe systems, among which

is the centralized structure illustrated in Figure 6.9( b). In this

arrangement. the computer system is organized as a hierarchy, with the central

[host} computer coordinating several satellite computers that are each

responsible for a number of CNC machines. Alternative LAN structures are

possible.each with its relative advantages and disadvantagcaLocal area networks

in different sections and departments of a plant arc often interconnected in

plant wide and corporate-wide networks.

Related Topics