Chapter: Electronic Circuits : Biasing of Discrete BJT and MOSFET

Diode and Thermistor Compensation technique

Compensation technique:

It refers to the use of temperature sensitive devices such as diodes, transistors, thermistors which provide compensating voltage and current to maintain Q point stable.

1. Diode Compensation Techniques

Compensation for VBE:

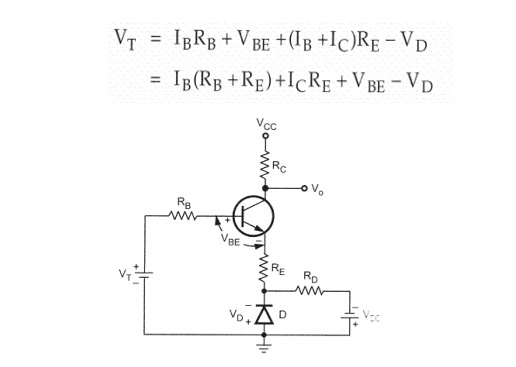

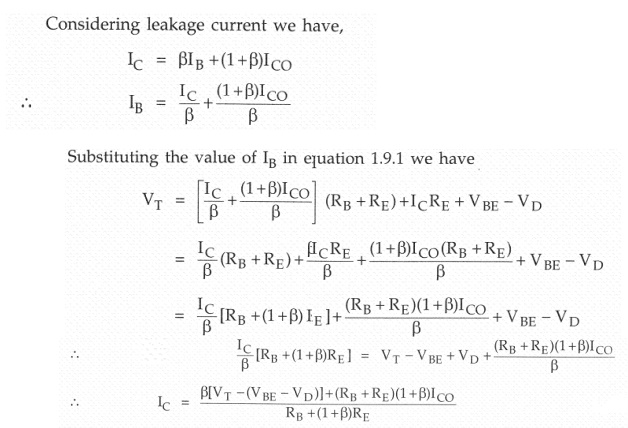

a) Diode in Emitter Circuit

Diagram

shows the voltage divider bias with bias compensation technique.Here, separate

supply VDD is used to keep diode in forward If biased condition. If

the diode used in the circuit is of same material and type as the transistor,

the voltage across the diode will have the same temperature coefficient as the

base to emitter voltage VBE . So when VBE changes by ∂ VBE with change in

temperature, VD changes by VD and ∂ VD~=~∂ VBE,

the changes tend to cancel each other. Apply*g KVL to the base circuit of Fig.

,we have

Figure: Stabilization by means of voltage divider bias and diode Compensation Technique

As VD tracks VBE with respect to temperature it is clear that IC will be insensitive to variations in VBE .

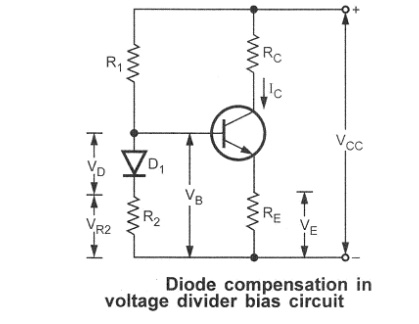

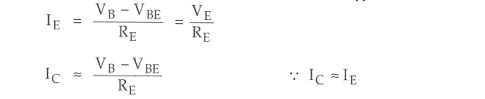

Diode in voltage divider circuit

Diode is

connected in series with resistance R2 in the voltage divider

circuit and it is forward biased condition.

For

voltage divider bias,

When VBE

changes with temperature, IC also changes

To cancel

the changes in IC , one diode is used in the circuit for

compensation

The

voltage at the base VB is give as

Substituting this value in equation IC,

we get,

The

changes cancel each other , so the collector current is given as

The

changes in VBE. Due to temperature are compensated by changes in the

diode voltage which keeps IC stable at Q point.

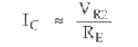

Compensation for ICO

*

In germanium transistor changes in ICO

with temperature plays an important role collector current stability

*

The diode is kept at reverse bias condition ,so

only leakage current flows

*

Io

increases then ICO also increases

As I is

constant , IC also remains constant. We can say that changes by ICO

with temperature are compensated by diode and collector current remains

constant

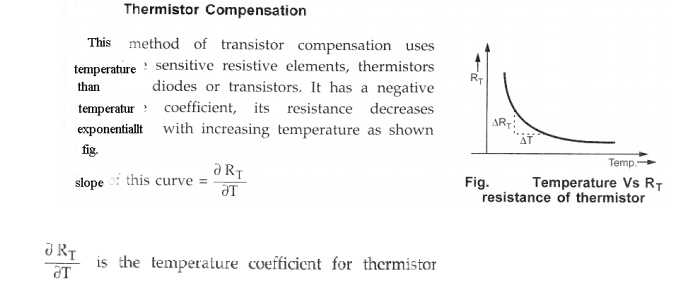

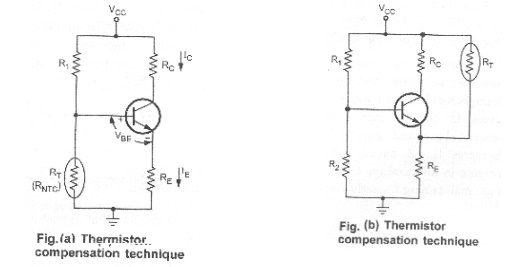

2. Thermistor Compensation

With

increase of temperature ,RT decreases. Hence the voltage drop across

it also decreases. That is VBE decreases which reduces IB

.this will offset the increased collector current with temperature.

The

equation shows if there is increase in ICO and decrease in IB

keeps IC almost constant.

Fig (b)

shows another thermistor compensation technique . Here, thermistor is connected

between emitter and Vcc to minimize the increase in collector current due to

changes in ICO, VBE, or beta with temperature .IC increases with

temperature and RT decreases with increase in temperature.

Therefore, current flowing through RE increases, which increases the voltage drop

across it. E - B junction is forward biased. But due to increase in voltage

drop across RE, emitter is made more positive, which reduces the

forward bias voltage VBE. Hence, bias current reduces.

As Ico

increases with temperature, IB decreases and hence. IC remains

constant

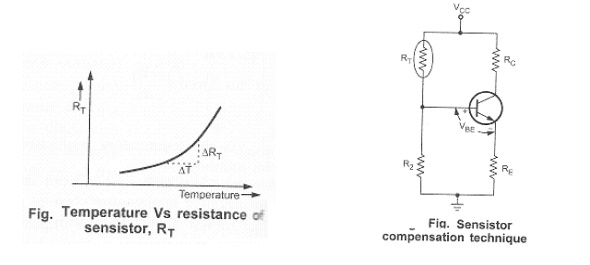

Sensistor Compensation technique

This

method of transistor compensation uses temperature sensitive resistive element,

sensistors rather than diodes or transistors. It has a positive temperature

coefficient, its resistance increases exponentially with increasing temperature

as shown in the Fig

Slope of

this curve =

is the

temperature coefficient for thermistor and the slope is positive So we can say

that sensistor has positive temperature coefficient of resistance (PTC).

is the

temperature coefficient for thermistor and the slope is positive So we can say

that sensistor has positive temperature coefficient of resistance (PTC).

Fig.

shows sensistor compensation R1 is replaced by sensistor RT

in self bias circuit. Now, RT and R2 resistors of the

potential divider. As temperature increases, RT increases which decreases the

current flowing through it. Hence current through R2 decreases which reduces

the voltages drop across it. Voltage drop across R2 is the voltage between base

and ground. So VBE reduces which decreases 16. It means, when ICBO

increases with increase in temperature, IB reduces due to reduction

in VBE, maintaining IC fairly constant.

Related Topics