Chapter: Civil : Railway Airport Harbour Engineering : Harbour Engineering

harbors: Tank Vessels

Tank

Vessels

TANKERS

Tankers move large bulk

petroleum cargo with speed and safety. Petroleum base terminals should be able

to receive tankers that are at least 600 feet long with a draft of 35 feet.

Tankers and their equipment are described below.

Cargo

Space

Most of a tanker hull

is used to carry liquid cargo. Cargo space varies among different types of

tankers. Cargo space is divided into tank compartments by bulkheads which run

the length and width of the tanker. The tank compartment is usually separated

from fore and aft sections of the tanker by narrow, empty, liquid-tight

compartments called cofferdams. Each tank compartment has a hatch and liquid-tight

hatch cover. An-ullage sounding hole with a hinged cover is usually in each

hatch cover. Tank compartments may have heating coils for heating cargo of

heavy oil to viscosities suitable for pumping.

Vent

Lines

Vent lines are usually

between each tank and hatch. At the hatch, the vent lines connect to headers.

The headers extend up the masts and have flame arresters at the top. Vapors

caused by agitation or high temperature of product are vented through these

lines. Each vent line is fitted with a vacuum relief valve. When vapors

condense in the tank because of low temperature, the relief valve permits

intake of air to relieve any vacuum created.

Pipeline

and Pumping Systems

A complex cargo line

system controls product flow during loading and discharging and while the

vessel is under way. Tank farm pumps or booster pumps are normally used to load

tankers. Tankers usually have cargo pumps for pumping cargo ashore through the

pipeline. Some tankers also have stripping systems used to strip the tanks dry

of ballast.

Fire-Fighting

Equipment

Tanker fire-fighting

equipment for the deck includes fire hoses, axes, buckets, and hand fire

extinguishers. There may be a carbon dioxide fire extinguisher system for

protecting fireroom bilges and electrical machinery. Most tankers also have a

steam smothering system that can be used to fight fires. The main line of this

system connects to the ship's auxiliary steam line through the master valve in

the boiler room. It runs forward along the deck with a branch for each fuel and

cargo tank and cofferdam. Branch lines also run to the forward holds, the pump

room, and other areas.

LIQUID-CARGO

BARGES

Military liquid-cargo

barges are steel watercraft. They move bulk petroleum products. Some are made

for short distance hauls in harbor, coastal, or inland waters. Others are made

for self delivery to an overseas destination and are self-sustaining for

extended periods of operation. Barges have no propelling machinery; therefore,

they require the services of a tug to move. A small tug is used for harbors and

inland waterways while a large tug is used for coastal and intertheater

missions.

Pumps

and Piping Systems

Some barges require

off-vessel equipment for discharging cargo, while other have their own

equipment. Self-discharging vessels generally use electrically powered rotary

pumps. The pumps are usually below the deck in the aft section or midship

section. As a fire precaution, the pump room is completely insulated from the

cargo and its gases. The piping systems on barges vary widely. There may be

several pipelines, depending on the number of products carried. Vessels

carrying light oils usually have pipelines with bellmouthed fittings. These

fittings extend almost to the tank bottom. A stripper line, extending until it

is almost flush with the tank bottom, is used to pump any oil left at the

bottom of the tank. Vessels carrying heavy fuel oils and asphalts are usually

equipped with 12- to 16-inch pumps and suitable pipelines.

Types

of Barges

The military has

225-barrel-capacity and 4,160-barrel-capacity steel hull barges in its

inventory. They are described below.

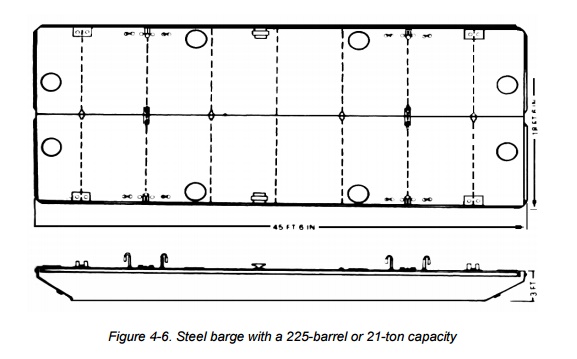

The

225-barrel Steel Barge

The barge (Figure 4-6) can carry limited quantities

of liquid (225 barrels) or dry cargo (21 long tons) about harbors or inland

waterways. Although this barge can carry limited quantities of liquid cargo, it

does not have integral liquid-cargo pumps. It has an overall length of 45 feet

6 inches, an 18-foot 6-inch beam, and a molded depth of 3 feet. It has a

displacement of 33 long tons loaded and a maximum draft of 1 foot 8 inches

loaded. This barge consists of two sections joined end-to-end. The military has

limited quantities of this barge remaining in its inventory. It is not

considered a bulk transporter because of the limited capacity and the lack of

integral pumping capability.

Figure

4-6. Steel barge with a 225-barrel or 21-ton capacity

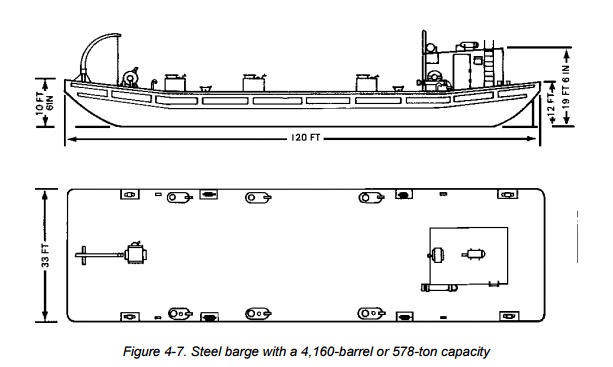

The

4,160-Barrel Steel Barge

This barge (Figure 4-7) can carry 4,160 barrels of

bulk liquid cargo or 578 long tons of dry cargo. The barge has an overall

length of 120 feet, a 33-foot beam, and a molded depth of 10 feet 6 inches. It

has an integral diesel-engine driven, liquid-cargo pump to receive and

discharge liquid cargo.

Figure

4-7. Steel barge with a 4,160-barrel or 578-ton capacity

Uses

Sometimes tank barges

are used for temporary storage of bulk petroleum products. However, the main

uses for barges include the following:

§

Delivering fuel to and from shore

terminals and moored oceangoing vessels which are limited by the depth of

water.

§

Topping off partially loaded ocean

tankers when docking the tanker would be too expensive or impossible because of

the tide, wind, or depth of water.

§

Delivering bulk shipments of

gasoline and lubricating oils in refueling operations at harbors and on rivers.

§

Removing oil sludge from the tanks

of tankers and delivering it to shore tanks.

§

Moving petroleum products when it

is cheaper to do so by water than by tank car.

Fire-Fighting

Equipment

Fire-fighting equipment

for the deck includes fire hoses, axes, buckets, and hand fire extinguishers.

Most vessels have fire pumps and carbon dioxide for fires below deck. Pressure

and flow are controlled by a master valve. In case of fire, carbon dioxide is

fed into the cargo tank to smother the flames. Some modern vessels have an

inert gas system fitted to the liquid-cargo tanks. This system provides a

positive gas pressure to the cargo tank. The gas is so deficient in oxygen that

it renders the atmosphere in the liquid cargo tanks incapable of supporting

combustion.

Related Topics