Chapter: Civil : Railway Airport Harbour Engineering : Harbour Engineering

harbors: Loading and Unloading Operations

Loading

and Unloading Operations

RESPONSIBILITIES

Commanders of

commercial tank vessels and commanding officers of military tank vessels are

responsible for the loading plans for their vessels. Their decisions are final

concerning the cargo layout. Petroleum shore inspectors inspect all vessel

tanks and pipeline systems before loading. Their decisions on quality control

of product are final. The inspectors review the loading plans and consider

bulkheads, lines, tank capacities, and trim. In the case of split cargo, the

inspectors must ensure that the vessel is physically able to carry two or more

grades of products without contamination. The inspectors make sure that

bulkheads are secure and that there are double valves or line blanks to

separate and to protect each system. If valves are used they must be lashed and

sealed in the proper position and the seal numbers must be placed on the

shipping document. Shore operators must make sure that precautions are taken

against fire, product contamination, and safety hazards. All loading plans must

be coordinated between the ship's officer and the responsible shore authority.

Shore attendants should know loading terms and factors governing vessel loading

and unloading.

LOADING

INFORMATION

Below are the various types of data used to describe

the loading capacity of a vessel.

§

Gross Tonnage. Gross tonnage is the

total internal cubic capacity of a vessel less exempted spaces, such as tanks

for ballast water. This weight is expressed in units of 100 cubic feet per ton.

§

Net Tonnage. Net tonnage is the

registered tonnage of a ship after deductions have been made from the gross

tonnage. Examples of deductions are crew and navigation spaces.

§

Light Displacement. Light

displacement is the weight of the vessel. This does not include the weight of

cargo, passengers, fuel, water, stores, and other items that are needed on a

voyage.

§

Loaded Displacement. Loaded

displacement is the total weight of the vessel. This includes the weight of

cargo, passengers, fuel, water, stores, and other items that are needed on a

voyage.

§

Deadweight Tonnage. Deadweight

tonnage is the carrying capacity of a vessel in long tons. It is the difference

between light and loaded displacement.

§

Cargo Deadweight Tonnage. Cargo

deadweight tonnage is the number of long tons left after the weight of fuel,

water, stores, and other items needed on a voyage has been deducted from the

total deadweight of the vessel.

§

Barrel Capacity. Barrel capacity is

the volume of cargo expressed in US barrels. A US barrel equals 42 gallons.

§

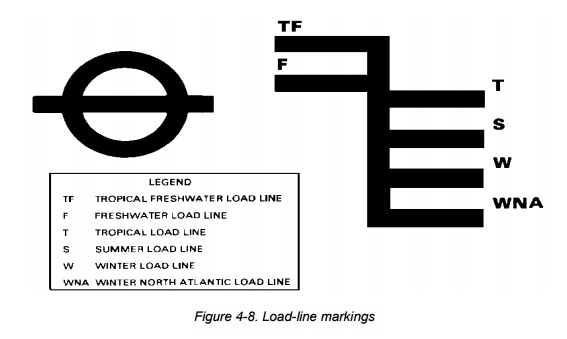

Load Line. The load line is the

line that shows the maximum mean draft to which a vessel may be lawfully

submerged. It is the lower limit of the freeboard for different conditions and

seasons. Freeboard is the vertical distance amidships from the upper edge of

the deck line to the upper edge of the load line. Load lines, set by proper

authority, must be permanently and clearly marked on the vessel next to the

load lines (Figure 4-8). The disk must be amidships below the deck line. The

authority responsible for assigning load lines may be shown by letters, such as

A-B for American Bureau of Shipping, alongside the disk and above the

centerline. International load line certificates, issued by the Coast Guard,

certify that the load line is correct. The horizontal lines mark the maximum

load line for different conditions and different seasons.

Figure

4-8. Load-line markings

§

Draft. Draft is the depth of water

a vessel draws. Draft marks are painted on either side of the bow and stern of

a vessel. They show the depth to which the bow and stern are in the water. The

draft marks, along with the immersion scale, show how many tons of cargo are

required to immerse the vessel 1 inch at any draft according to the deadweight

scale on the vessel's plan.

§

Trim. Trim is the difference

between the bow draft and stern draft of a vessel. To trim a vessel is to

arrange the cargo weights to get the desired bow and stern drafts. Trim tables,

based on inch trim movement formulas, may be used to determine how weight

distribution affects the draft and trim of a loaded vessel. The number of tons

needed in any compartment to alter the trim of a vessel 1 inch can be found in

these tables.

§

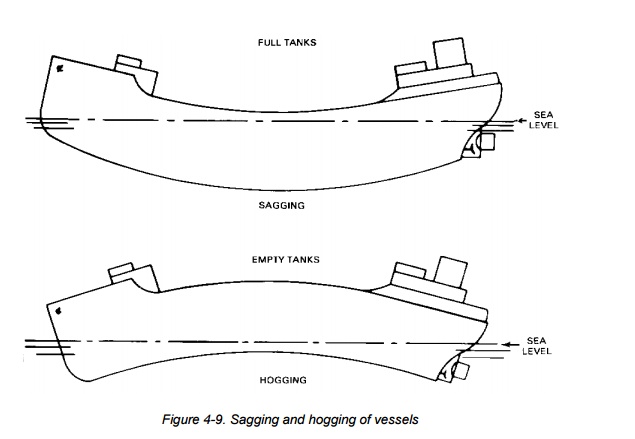

Sag. A vessel sags when the middle

of its structure sinks below the bow and stern (Figure 4-9). A loaded tank

vessel tends to sag due to the weight of the cargo in the tank section. It is

most noticeable midship. Sagging may cause excess stress if the weight is

concentrated in the midship cargo tank section. Since sag reduces freeboard,

the amount of cargo that can be carried is reduced. Sagging can be reduced if

more weight is put in the end tanks and less weight is put in the center tanks.

Weight should not be concentrated in any one section even while tanks are being

loaded.

§

Hog. A vessel hogs when the bow and

stern are lower than the midship section (Figure 4-9). An empty vessel tends to

hog because the bow and stern sections weigh more than the midship. Hogging

causes the center of the vessel to carry most of the stress. Hogging can be

avoided with proper loading and ballasting. Tables supplied with each vessel

can be used to determine bow-to-stern stress while the vessel is being loaded

and ballasted.

Figure 4-9. Sagging and hogging of vessels

Related Topics