Chapter: Mechanical : Metrology and Measurements : Laser Metrology

Use of Laser

Use of Laser

· Laser Telemetric

system

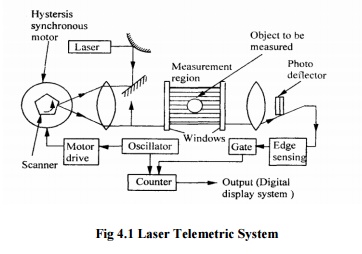

Laser telemetric system is a non-contact

gauge that measures with a collimated laser beam. It measures at the rate of

150 scans per second. It basically consists of three components, a transmitter,

a receiver and processor electronics. The transmitter module produces a

collimated parallel scanning laser beam moving at a high constant, linear

speed. The scanning beam appears a red line. The receiver module collects and

photoelically senses the laser light transmitted past the object being

measured. The processor electronics takes the received signals to convert them

10 a convenient form and displays the dimension being gauged. The transmitter

contains a low power helium-neon gas laser and its power supply, a specially

designed collimating lens, a synchronous motor, a multi faceted reflector

prism, a synchronous pulse photo detector and a protective replaceable window.

The high speed of scanning permits on line gauging and thus it is possible to

detect changes in dimensions when components are moving on a continuous product

such as in rolling process moving at very high speed. There is no need of

waiting or product to cool for taking measurements. This system can also be

applied on production machines and control then with closed feedback loops.

Since the output of this system is available in digital form, it can run a

process controller limit alarms can be provided and output can be taken on

digital printer.

Fig

4.1 Laser Telemetric System

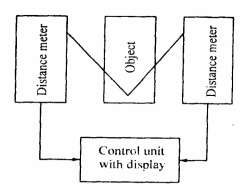

· Laser and LED based distance measuring instruments

These can measure distances from I to

2in with accuracy of the order of 0. 1 to 1% of the measuring range When the

light emitted by laser or LED hits an object, scatter and some of this

scattered light is seen by a position sensitive detector or diode array. If the

distance between the measuring head and the object changes. The angle at which

the light enters the detector will also change. The angle of deviation is

calibrated in terms of distance and output is provided as 0-2OmA. Such

instruments are very reliable because there are no moving parts their response

time is milliseconds. The measuring system uses two distance meters placed at

equal distance on either side of the object and a control unit to measure the

thickness of an object. The distance meter is focused at the centre of the

object.

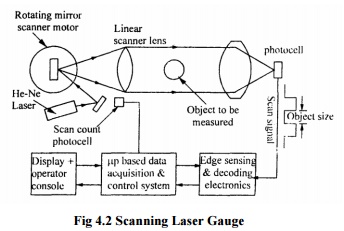

· Scanning Laser gauge

Fig shows a schematic diagram of a

scanning laser gauge. It consist of transmitter, receives and processor

electronics. A thin band of scanning laser light is made to pass

through a linear scanner lensbjectplacedtoina

parallelrender i beam, casts a time dependent shadow. Signal from the light

entering the photocell

(receiver) arc proc by a microprocessor to provide

display of the dimension represented by the time difference between the shadow

edges. It can provide results to an accuracy of0.25 for 10—50mm diameter

objects. It can be used for objects 0.05mm to 450mm diameter; and offers

repeatability of 0.1µm

· Photo diode away imaging

The

system comprises of laser source, imaging optics. Photo-diode array. Signal

processor and display unit. For large parts, two arrays in which one for each

edge are used. Accuracies as high as 0.05 µm have been achieved.

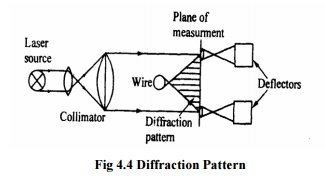

· Diffraction pattern technique

These are used to measure small gaps and

small diameter parts. A parallel coherent laser beam is diffracted by a small

part and a lens on a linear diode array focuses the resultant pattern. Its use

is restricted to small wires. The measurement accuracy is more for smaller

parts. The distance between the alternating light and dark hands in the

diffraction pattern is a (tired function of the wile diameter, wavelength of

laser beam and the focal length of the lens.

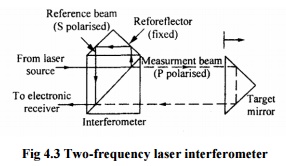

· Two- frequency laser interferometer

Fig.

shows schematic arrangement. This consists of two frequency laser head, beam

directing and splitting optics, measurement optics, receivers, and wavelength

compensators and electronics. It is ideally suited for measuring linear

positioning straightness in two planes, pitch and yaw.

The two-frequency laser head provides

one frequency with P-polarization and another frequency with S-polarization.

The laser beam is split at the polarizing beam splitter into its two separate

frequencies. The measuring beam is directed through the interferometer to

reflect off a target mirror or retro reflector attached to the object to be

measured. The reference beam is reflected from fixed retro reflector. The

measurement beam on its return path recombines with the reference beam and is

directed to the electronic receiver.

· Gauging wide diameter from the diffraction pattern

formed in a laser

Figure

shows a method of measuring the diameter of thin wire using the interference

fringes resulting from diffraction of the light by the wire in the laser beam.

A measure of the diameter can be obtained by moving the photo detector until

the output is restored to its original value. Variation in wire diameter as

small as 0.2% over wire diameter from 0.005 to 0.2mm can be measured.

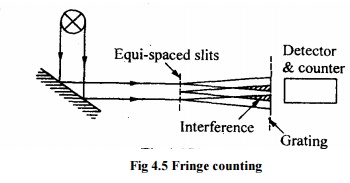

Figure

shows the length measurement by fringe counting. The laser output, which may be

incoherent illumines three slits at a time in the first plane which form

interference fringes. The movement can be determined by a detector. The total

number of slits in the first plane is governed by the length over which

measurement is required

The spacing between the slits and

distance of the slit to the plane of the grating depend on the wavelength of

the light used.

Related Topics