Chapter: Mechanical : Metrology and Measurements : Laser Metrology

Computer Controlled Co-Ordinate Measuring Machine

Computer Controlled

Co-Ordinate Measuring Machine

·

The measurements, inspection of parts

for dimension form, surface characteristics and position of geometrical

elements are done at the same time.

·

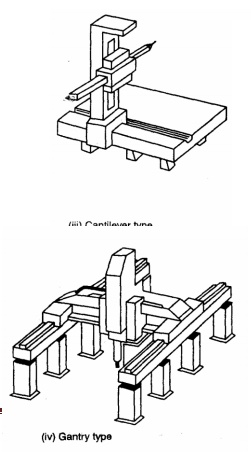

Mechanical system can be divided into

four basic types. The selection will be depends on the application.

1. Column

type.

2. Bridge

type.

3. Cantilever

type.

4. Gantry

type.

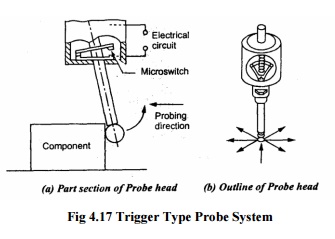

All these machines use

probes which may be trigger type or measuring type. This is connected to the

spindle in Z direction. The main features of this system are shown in figure

Fig 4.15 Column Type

Fig 4.16 Bridge Type

Trigger type probe

system

Fig

4.17 Trigger Type Probe System

·

The buckling mechanism is a three point

hearing the contacts which are arranged at 1200 around the circumference. These

contacts act as electrical micro switches.

·

When being touched in any probing

direction one or f contacts is lifted off and the current is broken, thus

generating a pulse, when the circuit is opened, the co-ordinate positions are

read and stored.

·

After probing the spring ensures the

perfect zero position of the three-point bearing. The probing force is

determined by the pre stressed force of the spring with this probe system data

acquisition is always dynamic and therefore the measuring time is shorter than

in static principle.

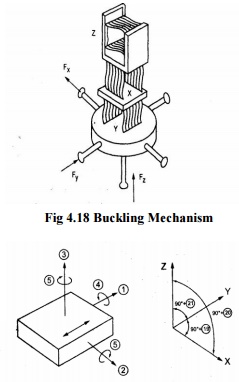

Measuring

type probe system

• It is

a very small co-ordinate measuring machine in which the buckling mechanism

consists of parallel guide ways when probing the spring parallelogram are

deflected from their initial position.

• Since

the entire system is free from, torsion, friction, the displacement can be

measured easily.

Fig 4.18 Buckling Mechanism

• The mathematical

model of the

mechanical system is shown in figure. If the components of the CMM are

assumed as rigid bodies, the deviations of a carriage can be described by three

displacement deviations.

• Parallel

to the axes 1, 2 and 3 and by three rotational deviations about the axes 4, 5

and 6.Similarly deviations 7-12 occur for carriage and 13-18 occur for Z

carriage and the three squareness deviations 19, 20 and 21 are to be measured

and to be treated in the mathematical model.

• Moving

the probe stylus in the Y direction the co-ordinate system L is not a straight line

but a curved one due to errors in the guide.

• If

moving on measure line L further corrections are required in X, Y and Z

coordinates due to the offsets X and Z from curve L resulting from the pitch

angle 5, the roll angle 4 and the yaw angle 6.

• Similarly

the deviations of all three carriages and the squareness errors can be taken

into account.

• The

effect of error correction can be tested by means of calibrated step gauges.

The

following test items are carried out for CMM.

(i)Measurement

accuracy

a. Axial length measuring accuracy b.Volumetric

length measuring accuracy

(ii)Axial

motion accuracy

a. Linear

displacement accuracy

b. Straightness

c. Perpendicularity

d. Pitch,

Yaw and roll.

The axial length measuring accuracy is

tested at the lowest position of the Z-axis. The lengths tested are

approximately 1/10, 1/5, 2/5, 3/5 and 4/5 of the measuring range of each axis

of CMM. Tile test is repeated five times for each measuring length and results

plotted and value of measuring accuracy is derived.

Related Topics