Chapter: Mechanical : Metrology and Measurements : Laser Metrology

Co-Ordinate Measuring Machines

CO-ORDINATE MEASURING

MACHINES

Measuring machines are used for

measurement of length over the outer surfaces of a length bar or any other long

member. The member may be either rounded or flat and parallel. It is more

useful and advantageous than vernier calipers, micrometer, screw gauges etc.

the measuring machines are generally universal character and can be used for

works of varied nature. The co-ordinate measuring machine is used for contact

inspection of parts. When used for computer-integrated manufacturing these

machines are controlled by computer numerical control. General software is

provided for reverse engineering complex shaped objects. The component is

digitized using CNC, CMM and it is then converted into a computer model which

gives the two surface of the component. These advances include for automatic

work part alignment on the table. Savings in inspection 5 to 10 percent of the

time is required on a CMM compared to manual inspection methods.

Types of Measuring

Machines

1. Length

bar measuring machine.

2. Newall

measuring machine.

3. Universal

measuring machine.

4. Co-ordinate

measuring machine.

5. Computer

controlled co-ordinate measuring machine.

Constructions of CMM

Co-ordinate measuring machines are very

useful for three dimensional measurements. These machines have movements in

X-Y-Z co-ordinate, controlled and measured easily by using touch probes. These

measurements can be made by positioning the probe by hand, or automatically in

more expensive machines. Reasonable accuracies are 5 micro in. or 1 micrometer.

The method these machines work on is measurement of the position of the probe

using linear position sensors. These are based on moiré fringe patterns (also

used in other systems). Transducer is provided in tilt directions for giving

digital display and senses positive and negative direction.

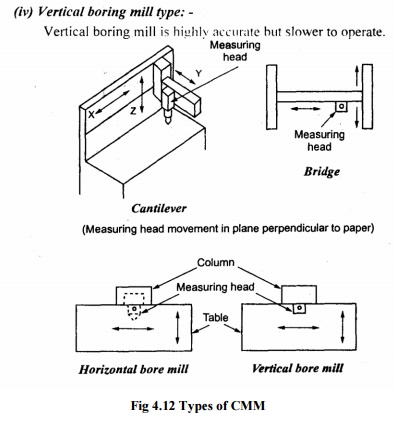

Types of CMM

(i) Cantilever type

The cantilever type is very easy to load

and unload, but mechanical error takes place because of sag or deflection in

Y-axis.

(ii)

Bridge type

Bridge

type is more difficult to load but less sensitive to mechanical errors.

(iii) Horizontal boring Mill type

This is best suited for large heavy work

pieces.

Fig 4.12 Types of CMM

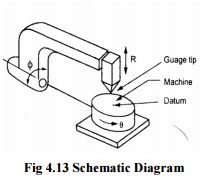

Working

Principle

CMM is used for measuring the distance

between two holes. The work piece is clamped to the worktable and aligned for

three measuring slides x, y and z. The measuring head provides a taper probe

tip which is seated in first datum hole and the position of probe digital read

out is set to zero. The probe is then moved to successive holes, the read out

represent the co-ordinate part print hole location with respect to the datum

hole. Automatic recording and data processing units are provided to carry out

complex geometric and statistical analysis. Special co-ordinate measuring

machines are provided both linear and rotary axes. This can measure various

features of parts like cone, cylinder and hemisphere. The prime advantage of

co-ordinate measuring machine is the quicker inspection and accurate

measurements.

Fig 4.13 Schematic

Diagram

Causes of Errors in CMM

1)

The table and probes are in imperfect

alignment. The probes may have a degree of run out and move up and down in the

Z-axis may cause perpendicularity errors. So CMM should be calibrated with

master plates before using the machine.

2) Dimensional

errors of a CMM is influenced by

·

Straightness and perpendicularity of the

guide ways.

·

Scale division and adjustment.

·

Probe length.

·

Probe system calibration, repeatability,

zero point setting and reversal error.

·

Error due to digitization.

·

Environment

3)

Other errors can be controlled by the

manufacture and minimized by the measuring software. The length of the probe

should be minimum to reduce deflection.

4)

The weight of the work piece may change

the geometry of the guide ways and therefore, the work piece must not exceed

maximum weight.

5)

Variation in temperature of CMM,

specimen and measuring lab influence the uncertainly of measurements.

6)

Translation errors occur from error in

the scale division and error in straightness perpendicular to the corresponding

axis direction.

7) Perpendicularity

error occurs if three axes are not orthogonal.

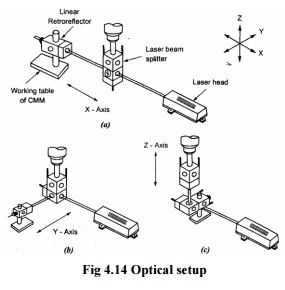

5 Calibration

of Three Co-Ordinate Measuring Machine

The optical set up for the V calibration is shown in

figure

The laser head is mounted on the tripod stand and

its height is adjusted corresponding to the working table of CMM. The

interferometer contains a polarized beam splitter which reflects F1 component

of the laser beam and the F2 Component parts through. The retro reflector is a

polished trihedral glass prism. It reflects the laser beam back along a line

parallel to the original beam by twice the distance. For distance measurement

the F1 and F2 beams that leave the laser head are aimed at the interferometer

which splits F1 and F2 via polarizing beaming splitter. Component F1 becomes

the fixed distance path and F2 is sent to a target which reflects it back to

the interferometer. Relative motion between the interferometer and the remote

retro reflector causes a Dopper shift in the returned frequency. Therefore the

laser head sees a frequency difference given by F1-F2 ± ΔF2. The-F2 ±F1ΔF2

signal that is external interferometer is compared in the measurement display

unit to the reference signal. The difference ΔF2 is related to microscope of

CMM is set at zero and the laser display unit is also set at zero. The CMM

microscope is then set at the following points and the display units are

noted.1 to 10mm, every mm and 10 to 200mm, in steps of 10mm. The accuracy of

linear measurements is affected by changes in air temperature, pressure and

humidity.

Performance of CMM

·

Geometrical accuracies such as positioning accuracy, Straightness and

Squareness.

Related Topics