Chapter: Mechanical : Metrology and Measurements : Laser Metrology

Laser Interferometer

LASER INTERFEROMETER

It is possible to maintain the quality of

interference fringes over longer distance when lamp is replaced by a laser

source. Laser interferometer uses AC laser as the light source and the

measurements to be made over longer distance. Laser is a monochromatic optical

energy, which can be collimated into a directional beam AC. Laser

interferometer (ACLI) has the following advantages.

·

High repeatability

·

High accuracy

·

Long range optical path

·

Easy installations

·

Wear and tear

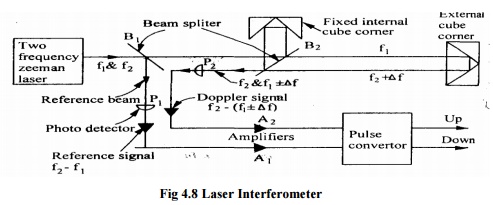

Schematic

arrangement of laser interferometer is shown in fig. Two-frequency zeeman laser

generates light of two slightly different frequencies with opposite circular

polarisation. These beams get split up by beam splitter B One part travels

towards B and from there to external cube corner here the displacement is to

the measured.

Fig 4.8 Laser Interferometer

This interferometer uses cube corner reflectors

which reflect light parallel to its angle of incidence. Beam splitter B2

optically separates the frequency J which alone is sent to the movable cube

corner reflector. The second frequency from B2 is sent to a fixed reflector

which then rejoins f1 at the beam splitter B2 to produce alternate light and

dark interference flicker at about 2 Mega cycles per second. Now if the movable

reflector moves, then the returning beam frequency Doppler-shifted slightly

up Thus the light beams moving towards photo detector P2 have

frequencies f2 and (f1 ± Δf1) and P2 changes these frequencies int signal from

beam splitter B2 and changes the reference beam frequencies f1 and f2 into

electrical signal. An AC amplifier A separates frequency. Difference signal f2

–f1 and A2 separates frequency difference signal. The pulse converter extracts

i. one cycle per half wavelength of motion. The up-down pulses are counted

electronically and displayed in analog or digital form.

Michelson

Interferometer

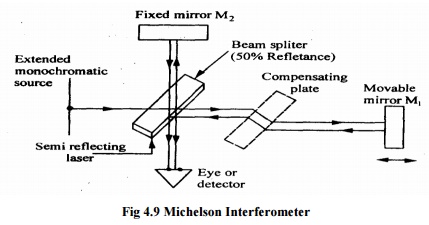

Michelson

interferometer consists of a monochromatic light source a beam splitter and two

mirrors. The schematic arrangement of Michelson interferometer is shown in fig.

The monochromatic light falls on a beam splitter, which splits the light into

two rays of equal intensity at right angles. One ray is transmitted to mirror

M1 and other is reflected through beam splitter to mirror M2,. From both these

mirrors, the rays are reflected back and these return at the semireflecting

surface from where they are transmitted to the eye. Mirror M2 is fixed and

mirror M1 is movable. If both the mirrors are at same distance from beam

splitter, then light will arrive in phase and observer will see bright spot due

to constructive interference. If movable mirror shifts by quarter wavelength,

then beam will return to observer 1800 out of phase and darkness will be

observed due to destructive interference

Each half-wave length of mirror travel produces a

change in the measured optical path of one wavelength and the reflected beam

from the moving mirror shifts through 360° phase change. When the reference

beam reflected from the fixed mirror and the beam reflected from the moving

mirror rejoin at the beam splitter, they alternately reinforce and cancel each

other as the mirror moves. Each cycle of intensity at the eye represents l/2 of

mirror travel. When white light source is used then a compensator plate is

introduced in each of the path of mirror M1 So that exactly the same amount of

glass is introduced in each of the path.

To

improve the Michelson interferometer

(i)

Use of laser the measurements can

be made over longer distances and highly accurate measurements when compared to

other monochromatic sources.

(ii)

Mirrors are replaced by cube-corner

reflector which reflects light parallel to its angle of incidence.

(iii)

Photocells are employed which

convert light intensity variation in voltage pulses to give the amount and

direction of position change.

Dual Frequency Laser

Interferometer

This instrument is used to measure

displacement, high-precision measurements of length, angle, speeds and

refractive indices as well as derived static and dynamic quantities. This

system can be used for both incremental displacement and angle measurements.

Due to large counting range it is possible to attain a resolution of 2mm in 10m

measuring range. Means are also provided to compensate for the influence of

ambient temperature, material temperature, atmospheric pressure and humidity

fluctuation

Twyman-Green

Interferometer

The

Twyman-Green interferometer is used as a polarizing interferometer with

variable amplitude balancing between sample and reference waves. For an exact

measurement of the test surface, the instrument error can be determined by an

absolute measurement. This error is compensated by storing the same in

microprocessor system and subtracting from the measurement of the test surface.

It

has following advantages

· It

permits testing of surface with wide varying reflectivity.

· It

avoids undesirable feedback of light reflected of the tested surface and the

instrument optics.

· It

enables utilization of the maximum available energy.

· Polarization

permits phase variation to be effected with the necessary precision.

Laser Viewers

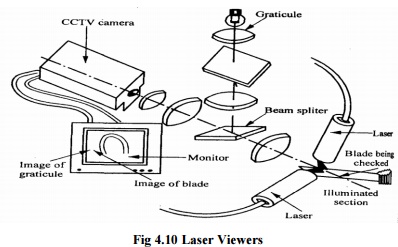

The

profile of complex components like turbine blades can be checked by the use of

optical techniques. It is based on use of laser and CCTV. A section of the

blade, around its edge is delineated by two flat beam of laser light. This part

of the edge is viewed at a narrow angle by the TV camera or beam splitter

Fig

4.10 Laser Viewers

Both

blade and graticule are displayed as magnified images on the monitor, the graticule

position being adjustable so that its image can be superimposed on the profile

image. The graticule is effectively viewed at the same angle as the blade. So,

distortion due to viewing angle affects both blade and graticule. This means

that the graticule images are direct 1:1.

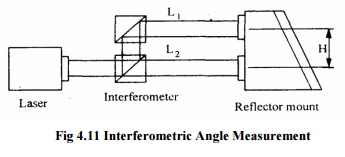

INTERFEROMETRIC

MEASUREMENT OF ANGLE

With

laser interferometer it is possible to measure length to accuracy of 1 part in

106 on a routine basis. With the help of two retro reflectors placed at a fixed

distance and a length measuring laser interferometer the change in angle can be

measured to an accuracy of 0.1 second. The device uses sine Principle. The line

joining the poles the retro-reflectors makes the hypotenuse of the right

triangle. The change in the path difference of the reflected beam represents

the side of the triangle opposite to the angle being measured. Such laser

interferometer can be used to measure an angle up to ± 10 degrees with a

resolution of 0. 1 second. The principle of operation is shown in fig.

Fig

4.11 Interferometric Angle Measurement

Laser Equipment for

Alignment Testing

This testing is particularly suitable in aircraft

production, shipbuilding etc. Where a number of components, spaced long

distance apart, have to be checked to a predetermine straight line. Other uses

of laser equipment are testing of flatness of machined surfaces, checking

square ness with the help of optical square etc. These consist of laser tube

will produces a cylindrical beam of laser about 10mm diameter and an auto

reflector with a high degree of accuracy. Laser tube consists of helium-neon

plasma tube in a heat aluminum cylindrical housing. The laser beam comes out of

the housing from its centre and parallel to t stability is the order of 0.2”detectorofhead

arcand per read out unit. Number of photocell are arranged to compare laser

beam in each half horizontally and vertically. This is housed on a shard which

has two adjustments to translate the

detector in its two orthogonal measuring directions perpendicular to the laser

beam. The devices detect the alignment of flat surfaces perpendicular to a

reference line of sight.

Related Topics