Chapter: Special Electrical Machines : Switched Reluctance Motor

Torque-Speed Characteristics of SRM(Switched Reluctance Motor)

TORQUE-SPEED CHARACTERISTICS

Torque

developed (i.e.) average torque developed but SRM depends upon the current wave

form of SRM phase winding. Current waveform depends upon the conduction period

and chopping details. It also depends upon the speed.

Consider

a case that conduction angle ϴ is

constant and the chopper duty cycle is 1.(i.e.) it conducts continuously. For

low speed operating condition, the current is assumed to be almost flat shaped.

Therefore the developed torque is constant. For high speed operating condition,

the current wave form gets changed and the average torque developed gets

reduced.

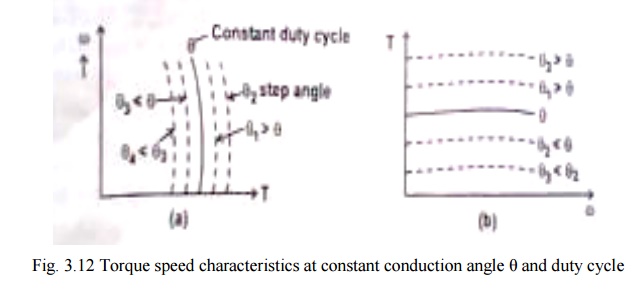

Fig.

3.12(a) represents the speed torque characteristics of SRM for constant ϴ and duty cycle. It is constant

at low speeds and slightly droops as speed increases. For various other constant

value of ϴ , the

family of curves for the same duty cycle is shown in fig.3.12.

Torque

speed characteristics for fixed ϴ and for

various duty cycles are shown in fig. 3.12. ϴ and duty

cycle are varied by suitably operating the semiconductor devices.

1. Torque Speed Capability Curve

Maximum

torque developed in a motor and the maximum power that can be transferred are

usually restricted by the mechanical subsystem design parameters.

For given

conduction angle the torque can be varied by varying the duty cycle of the

chopper. However the maximum torque developed is restricted to definite value

based on mechanical consideration.

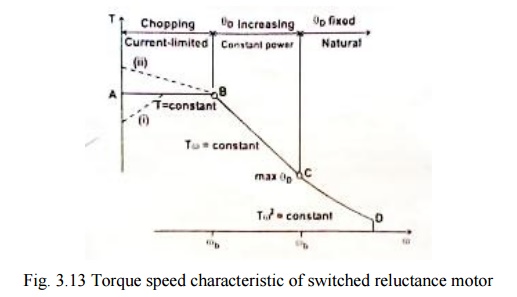

AB in the

fig.3.13 represents constant maximum torque region of operation.

At very

low speeds, the torque / speed capability curve may deviate from the clock

torque characteristics. If the chopping frequency is limited or if the

bandwidth of the current regulator is limited, it is difficult to limit the

current without the help of self emf of the motor and the current reference may

have to be reduced.

If very

low windage and core loss permit the chopper losses to be increased, so that

with higher current a higher torque is obtained. Under intermittent condition

of course very much higher torque can be obtained in any part of the speed

range up to Ѡ b.

The motor

current limits the torque below base speed. The ‗corner point‘ or base speed ‗Ѡ b‘ is

the highest speed at which maximum current can be supplied at rated voltage

with fixed firing angles. If these angles are still kept fixed, the maximum

torque at rated voltage decreases with speed squared. But if the conduction

angle is increased,(i.e.)ϴ on is

decreased, there is a considerable speed range over which maximum current can

be still be forced into the motor. This maintains the torque at a higher level

to maintain constant power characteristic. But the core losses and windage

losses increases with the speed. Thus the curve BC represents the maximum

permissible torque at each speed without exceeding the maximum permissible

power transferred. This region is obtained by varying ϴ D to its maximum value ϴ D max. ϴ D is dwell angle of the main

switching devices in each phase. Point C corresponds to maximum permissible

power; maximum permissible conduction angle

ϴ D max and duty cycle of the

chopper is unity.

Curve CD

represents TѠ 2 constant. The conduction angle is kept maximum and duty

cycle is maximum by maintaining TѠ 2 constant. D

corresponds to maximum Ѡ permissible.

The

region between the curve ABCD and X axis is the ―permissible region of

operation of SRM‖.

Related Topics