Chapter: Special Electrical Machines : Switched Reluctance Motor

Power Semiconductor Switching Circuits for SRM(Power Controllers)

POWER SEMICONDUCTOR SWITCHING

CIRCUITS FOR SRM (POWER CONTROLLERS)

The

selection of controller (converter) depends upon the application. One of the

main aspects of the research in SRM drives has been the converter design. The

main objectives of the design of the converter are performance of the drive and

cost of the drive.

The power

semiconductor switching circuits used are

1. Two power

semiconductor switching devices per phase and two diodes.

2. (n+1)

power semiconductor switching devices (n+1) diodes.

3. Phase

winding using bifilar wires.

4. Split-link

circuit used with even-phase number.

5. C-dump

circuit.

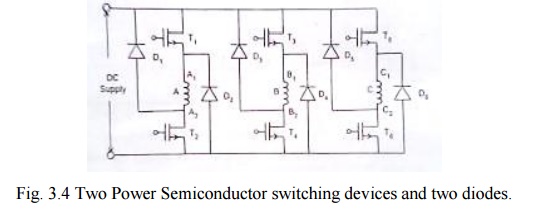

1. Two Power Semiconductor

Switching Devices per phase and two diodes

As shown

in fig 3.4 phase winding A is connected to the dc supply through power

semiconductor devices T1 and T2. Depending upon the rotor

position, when the phase winding A is to be energized the devices T1

and T2 are turned ON. When the phase winding is to be disconnected

from the supply (this instant is also dependent on the position of the shaft)

the devices T1 and T2 are turned off .The stored energy

in the phase winding A tends to maintain the current in the same direction.

This current passes from the winding through D1 and D2 to

the supply. Thus the stored energy is fed back to the mains.

Similarly

phase winding B & C are also switched on to the supply and switched off

from the supply in a cyclic manner. This circuit requires 2 power switching

devices and 2 diodes for each phase winding. For high speed operation it is

required to see that the stored energy can be fed back to the mains within the available

period.

Usually

the upper devices T1, T3 and T5 are turned on

and off from the signals obtained from the rotor position sensor .The duration

of conduction or angle of conduction θ can be controlled by using suitable

control circuitry .The lower devices T2, T4, T6

are controlled from signals obtained by chopping frequency signal. The current

in the phase winding is the result of logical AND ing of the rotor position

sensor and chopping frequency .As a result it is possible to vary the effective

phase current from a very low value to a high value .For varying the following

methods are available.

1. By

varying the duty cycle of the chopper.

2. By

varying the conduction angle of the devices.

Merits

v Control

of each phase is completely independent of the other phase.

v The

converter is able to free wheel during the chopping period at low speeds which

helps to reduce the reduce the switching frequency and thus the switching

losses of the converter.

v The

energy from the off going phase is feedback to the source, which results in

utilization of energy

Demerits

v Higher

number of switches required in each phase, which makes the converter expensive

and also used for low voltage applications.

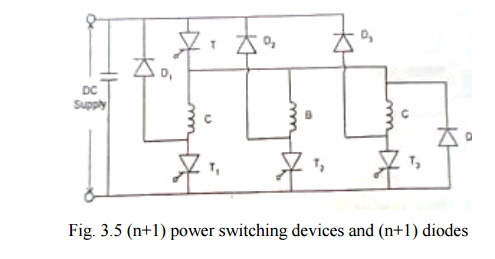

2. (n+1) power switching devices

and (n+1) diodes

This circuit

makes use of less number of power switching devices and diodes as shown in fig

3.5. When the (SCRs) switching devices T and T1 are turned on phase

winding A is energized from the dc supply. When these devices are turned off

the stored energy in the phase winding is fed back to the mains through diodes

D and D1. When devices T and T2 are turned on the phase winding B is

energized .When they are turned off ,the stored energy in B phase winding C is

switched on and off from the mains. The cycle gets repeated.

This

circuit makes use of (n+1) power switching devices and (n+1) diodes where n is

equal to the number of phases.

Merits

v The

converter uses low number of switching devices, which reduces the cost of the

converter.

v The

converter is able to freewheel during the chopping, thus reducing the switching

frequency and losses.

v Voltage

rating of all the switching devices and the diodes are V dc, which

is relatively low.

v The

energy for the off going phase is transferred back into the source, which results

in useful utilization of the energy and also improves the efficiency.

Demerits

v Disability

to magnetize a phase while the off going phase is still demagnetizing which

results in higher torque ripple during commutation.

v At higher

speeds of the off going phase cannot be de-energized fast enough because the

common switch ―T‖ keeps turnings on intermediately, disabling forced

demagnetization.

v The

common switch conducts for all the phases and thus has higher switching stress.

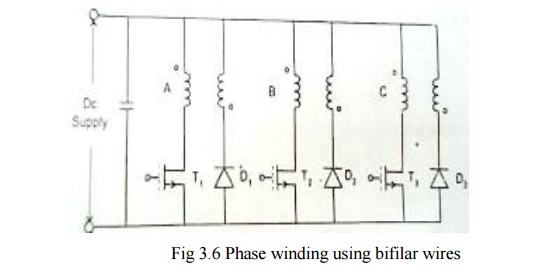

3. Phase winding using bifilar

wires

Each

phase winding has two exactly similar phase windings as shown in fig 3.6.For

this bifilar wires are used .Each phase consists of two identical windings and

are magnetically coupled when one of them are excited.

In

stepper motor, the purpose of bifilar winding is for bipolar excitation with a

reduced number of switching elements.

When T1

is turned on the dc current passes through the phase winding A. when the

devices T1 is turned off the stored energy in the magnetic field is

fed back to the dc source through the winding A‘ and D1 to the

supply.

The three

devices operate in a sequential way depending upon the signals obtained from

the rotor position sensor and the chopping signals for PWM technique obtained

from the controller.

Merits

v The

converter uses lower number of switching devices thus reducing the cost on the

converter.

v The

converter allows fast demagnetization of phases during commutation.

Demerits

v Bifilar

winding suffers from double number of connections.

v A poor

utilization of copper.

v Freewheeling

is not possible during chopping as the phases have -Vdc. this causes

of higher ripples in current and torque during chopping.

v The

imperfection in the coupling between the two winding causes voltage spikes

during turn off.

v The

copper loss associated with the auxiliary winding is unacceptable high for many

applications.

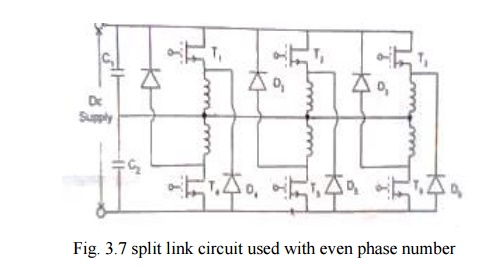

4. Split – link circuit used with even phase number

The

circuit shown in fig.3.7 is used in a range of highly efficient drives (from

4-80kw).

The main

power supply is split into two halves using split capacitors. During

conduction, energy is supplied to the phases by one half the power supply.

During commutation period, the phases demagnetize into other half of the power

supply.

When

switch T1 is turned on, phase winding 1 is energized by capacitor c1. When

switch T2 is turned off, the stored energy in the phase winding 1 is fed back

to the capacitor c2 through diode D4.

When T4

is turned on by capacitor C2 and phase winding 4 is energized. When switch T4

is turned off, stored energy in the winding 4 is feedback to the capacitor C1

through diode D1. The similar operation takes place in the remaining winding

also.

Merits

v It

requires lower number of switching devices.

v Faster

demagnetization of phases during commutation.

Demerits

v During

chopping, freewheeling is not possible as the phaser have the voltage Vdc/2. This causes higher switching

frequency and more losses.

v This is

not feasible for low voltage application.

v The

converter is fewer faults tolerant as fault in any phase will unbalance the

other phase that is connected to it.

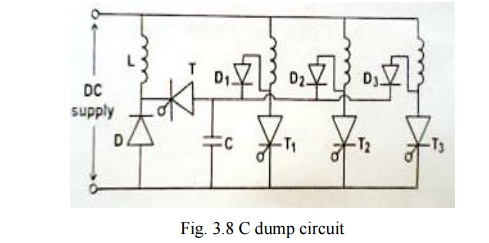

5. C-Dump circuit

In the C

dump circuit shown in fig. 3.8. the device count is reduced to ‗n‘ plus one

additional devices to bleed the stored energy from the dump capacitor C back to

supply via the step down chopper circuit. The mean capacitor voltage is

maintained well above the supply to permit rapid defluxing after commutation.

A control

failure in the energy-recovery circuit would result in the rapid build-up of

charge on the capacitor and if protective measures were not taken the entire

converter could fail from over voltage.

Demerits

v Dump

capacitor voltage is maintained ―2 Vdc‖ to allow fast demagnetization. But use

of a capacitor and an inductor in the dump circuit and also the voltage rating

of other devices is twice the bus voltage

v Monitoring

of the dump capacitor voltage 'C‘ and control of dump switch T makes the

converter very complicated and also the converter does not allow freewheeling.

Related Topics