Chapter: Special Electrical Machines : Switched Reluctance Motor

Hysterisis Type Current Regulation

HYSTERISIS TYPE CURRENT

REGULATION

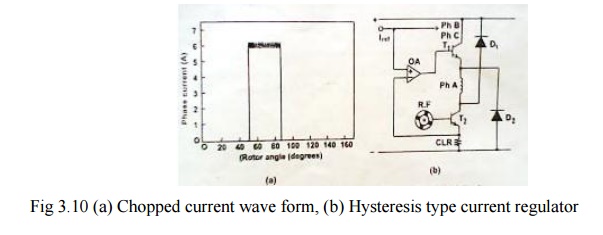

As by

this control circuit current is maintained more or less constant like

―hysteresis‖ throughout the conduction period in each phase it is known as

hysteresis type control. Fig 3.10 (a) shows the current waveform controlled by

the hysteresis type current regulator. The schematic arrangement of the control

circuit is shown in fig 3.10 (b).

Principle of operation

As shown

in fig. 3.10(b) the transducer (a tachogenerator) is connected from the rotor

and then the output signal from the transducer is given as a feedback signal at

the base of transistor T2. From the emitter of transistor T2,

the portion of the feedback signal (current) is fed at the input of the

operational amplifier (O.A). There it is compared with the reference current

and correspondingly after amplification the feedback signal is given at the

base of transistor T1. This signal in combination with collector

current will flow from the emitter of transistor T1 through A phase

winding of the machine. Thus the current through A phase winding can be

controlled depending on the requirement. CLR is the resistance for limiting the

current as per the design.

As the

current reference increase the torque increases. At low currents the torque is

roughly proportional to current squared but at higher current it becomes more

nearly linear. At very high currents, saturation decreases the torque per

ampere again. This type of control produces a constant-torque type of

characteristics.

With

loads whose torque increases monotonically with speed, such as fans and

blowers, speed adjustment is possible without tachometer feedback but general

feedback is needed to provide accurate speed control. In some cases the pulse

train from the soft position sensor may be used for speed feedback, but only at

relative high speeds.

As low

speeds, a larger number of pulses per revolution are necessary and this can be

generated by an optical encoder or resolver for alternatively by phase-locking

a high frequency oscillator to the pulses of the commutation sensor. System

with resolver-feedback or high-resolution optical encoders can work right down

to zero speed.

The

―hysteresis type‖ current regulator may require current transducers of wide

bandwidth, but the SR drive has the advantage that they can be grounded at one

end with the other connected to the negative terminal of the lower phase leg

switch. The sensors used are shunts or hall-effect sensors or sensefets with in

build current sensing.

Related Topics