Chapter: Power Plant Engineering Fundamental

Surface Condensers: Types, Advantages, Disadvantages, Requirement

SURFACE CONDENSERS

In surface condensers there is no

direct contact between the steam and cooling water and the condensate can be

re-used in the boiler: In such condenser even impure water can be used for

cooling purpose whereas the cooling water must be pure in jet condensers.

Although the capital cost and the space needed is more in surface condensers

but it is justified by the saving in running cost and increase in efficiency of

plant achieved by using this condenser. Depending upon the position of

condensate extraction pump, flow of condensate and arrangement of tubes the

surface condensers may be classified as follows:

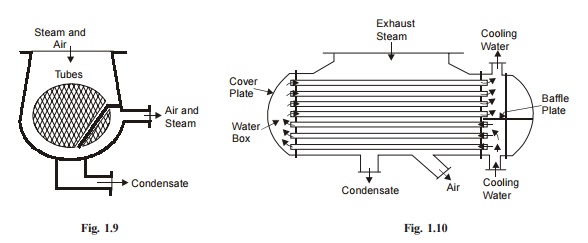

(i) Down flow type. Fig. 1.9 shows a

sectional view of dawn flow condenser. Steam enters at the top and flows

downward. The water flowing through the tubes in one direction lower half comes

out in the opposite direction in the upper half Fig. 1.10 shows a longitudinal

section of a two pass down-flow condenser.

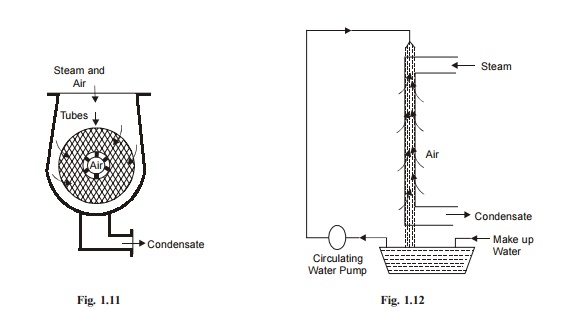

(ii) Central flow condenser. Fig. 1.11 shows

a central flow condenser. In this condenser the steam passages are all around

the periphery of the shell. Air is pumped away from the centre of the condenser.

The condensate moves radially towards the centre of tube nest. Some of the

exhaust steams while moving towards the centre meets the undercooled condensate

and pre-heats it thus reducing undercooling.

(iii) Evaporation condenser. In this

condenser (Fig. 1.12) steam to be condensed is passed through a series of tubes

and the cooling waterfalls over these tubes in the form of spray. A steam of

air flows over the tubes to increase evaporation of cooling water, which

further increases the condensation of steam.

ADVANTAGES

AND DISADVANTAGES OF A SURFACE CONDENSER

The various advantages of a surface condenser are as follows:

1.

The condensate can be used as boiler

feed water.

2. Cooling water of even poor quality can be used because the

cooling water does not come in direct contact with steam.

3.

High vacuum (about 73.5 cm of Hg) can

be obtained in the surface condenser. This increases the thermal efficiency of

the plant.

The various disadvantages of' the surface condenser are as

follows:

1.

The capital cost is more.

2.

The maintenance cost and running cost

of this condenser is high.

3.

It is bulky and requires more space.

REQUIREMENTS

OF A MODERN SURFACE CONDENSER

The requirements of ideal surface condenser used for power

plants are as follows:

The steam entering the condenser

should be evenly distributed over the whole cooling sur-face of the condenser

vessel with minimum pressure loss.

The amount of cooling water being

circulated in the condenser should be so regulated that the temperature of

cooling water leaving the condenser is equivalent to saturation temperature of

steam corresponding to steam pressure in the condenser.

This will help in preventing under cooling of condensate.

The deposition of dirt on the outer surface of tubes should be

prevented.

Passing the cooling water through the tubes and allowing the

steam to flow over the tubes achieve this.

There should be no air leakage into the condenser because

presence of air destroys the vacuum in the condenser and thus reduces the work

obtained per kg of steam. If there is leakage of air into the condenser air

extraction pump should be used to remove air as rapidly as possible.

Related Topics