Chapter: Power Plant Engineering Fundamental

Classification of Power Plant Cycle

CLASSIFICATION OF POWER PLANT CYCLE

Power plants cycle generally divided in to the following groups,

1 Vapour Power Cycle

(Carnot cycle, Rankine cycle, Regenerative cycle, Reheat cycle,

Binary vapour cycle)

2 Gas Power Cycles

(Otto cycle, Diesel cycle, Dual combustion cycle, Gas turbine

cycle.)

1

CARNOT CYCLE

This cycle is of great value to heat

power theory although it has not been possible to construct a practical plant

on this cycle. It has high thermodynamics efficiency.

It is a standard of comparison for all other cycles. The thermal

efficiency (η ) of Carnot cycle is as follows:

η

= (T1 - T2)/T1 where, T1 = Temperature of

heat source

T2 = Temperature of receiver

2

RANKINE CYCLE

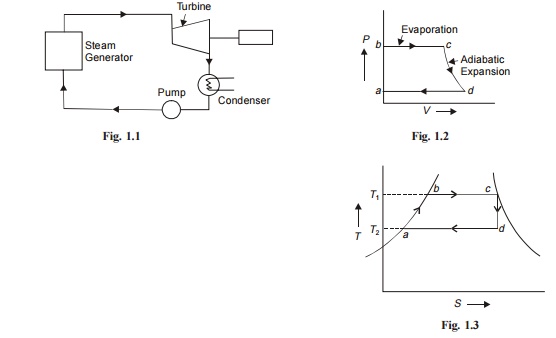

Steam engine and steam turbines in which steam is used as

working medium follow Rankine cycle. This cycle can be carried out in four

pieces of equipment joint by pipes for conveying working medium as shown in

Fig. 1.1. The cycle is represented on Pressure Volume P-V and S-T diagram as

shown in Figs. 1.2 and 1.3 respectively.

Efficiency of Rankine cycle

= (H1 - H2)/ (H1 - Hw2)

where, T1

Hl = Total heat of steam at entry

pressure

H2 = Total heat of steam at condenser

pressure (exhaust pressure)

Hw2= Total heat of water at exhaust

pressure

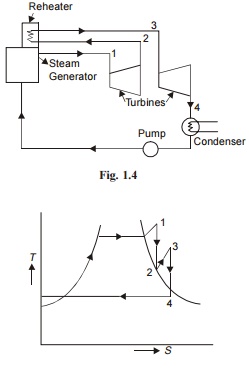

In this cycle steam is extracted from a suitable point in the

turbine and reheated generally to the original temperature by flue gases.

Reheating is generally used when the pressure is high say above 100 kg/cm2.

The various advantages of reheating are as follows:

(i)

It increases dryness fraction of steam at ex-haust so that blade erosion due to

impact of water particles is reduced.

(iii)

It increases the work done per kg of steam and this results in reduced size of

boiler.

The disadvantages of reheating are as follows:

(i)

Cost of plant is increased due to the

reheater and its long connections.

(ii)

It increases condenser capacity due to

in-creased dryness fraction.

If,

H1 = Total heat of steam at 1

H2 = Total heat of steam at 2

H3 = Total heat of steam at 3

H4 = Total heat of steam at 4

Hw4 = Total heat of steam at 4

Efficiency = {(H1 - H2) + (H3 - H4)}/{H1 + (H3 - H2) - Hw4}

4

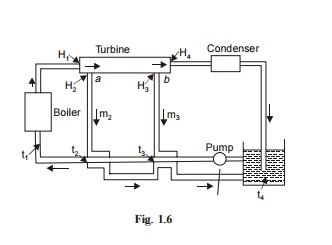

REGENERATIVE CYCLE (FEED WATER HEATING)

Let,

m2 = Weight of bled steam at a per kg of

feed water heated m2 = Weight of bled steam at a per kg of

feed water heated H1 =

Enthalpies of steam and water in boiler

Hw1

= Enthalpies of steam and water in boiler H2, H3 =

Enthalpies of steam at points a and b

t2,

t3 = Temperatures of

steam at points a and b

H4, Hw4

= Enthalpy of steam and water exhausted to hot well. Work done in turbine per

kg of feed water between entrance and a

= H1 - H2

Work done between a

and b = (1 - m2)(H2 - H3)

Work done between b and

exhaust = (1 - m2 - m3)(H3 - H4)

Total heat supplied per kg of feed water = H1 - Hw2

Efficiency (η ) = Total work done/Total heat supplied

{(H1 - H2) + (1 - m2)(H2 ? H3) + (1 - m2 - m3)(H3 ? H4)}/(H1 ? Hw2)

5

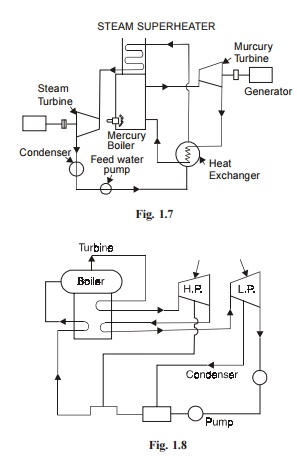

BINARY VAPOUR CYCLE

In this cycle two working fluids are used. Fig. 1.7 shows

Elements of Binary va-pour power plant. The mercury boiler heats the mercury

into mercury vapours in a dry and saturated state.

These mercury vapours expand in the mercury turbine and then

flow through heat exchanger where they transfer the heat to the feed water,

convert it into steam. The steam is passed through the steam super heater where

the steam is super-heated by the hot flue gases. The steam then expands in the

steam turbine.

6

REHEAT-REGENERATIVE CYCLE

In steam power plants using high steam pressure reheat

regenerative cycle is used. The ther-mal efficiency of this cycle is higher

than only re-heat or regenerative cycle. Fig. 1.8 shows the flow diagram of

reheat regenerative cycle. This cycle is commonly used to produce high pressure

steam (90 kg/cm2) to increase the cycle efficiency.

FORMULA

SUMMARY

Rankine efficiency

(H1 - H2)/(H1 - Hw2)

Efficiency ratio or Relative efficiency

Indicated or Brake thermal

efficiency/Rankine efficiency

Thermal efficiency = 3600/m(H1 - Hw2),

m = steam flow/kw hr

Carnot efficiency = (T1 - T2)/T1

Related Topics