Chapter: Power Plant Engineering Fundamental

Difference between Impulse and Reaction Turbine

MPULSE AND REACTION TURBINES

Hydraulic turbines are

required to transform fluid energy into usable mechanical energy as

effi-ciently as possible. Further depending on the site, the available fluid

energy may vary in its quantum of potential

and kinetic energy. Accordingly a suitable type of turbine needs to be selected

to perform the required job.

Based upon the basic

operating principle, water turbines are categorized into impulse and reaction

turbines depending on whether the pressure head available is fully or partially

converted into kinetic energy in the nozzle.

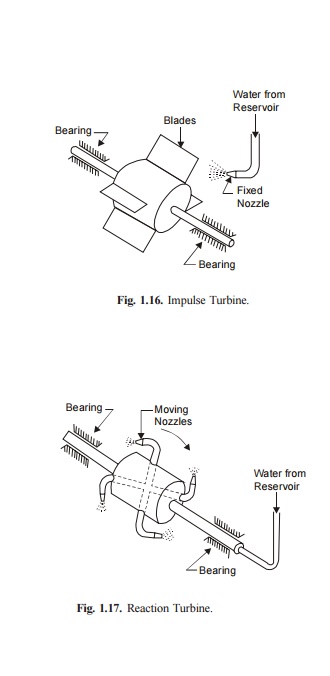

Impulse Turbine wherein the available

hydraulic energy is first converted into kinetic energy by means of an efficient nozzle. The high velocity jet issuing from

the nozzle then strikes a series of suitably shaped buckets fixed around the

rim of a wheel (Fig. 1.16). The buckets change the direction of jet without

changing its pressure. The resulting change in momentum sets buckets and wheel

into rotary motion and thus mechanical energy is made available at the turbine

shaft. The fluid jet leaves the runner with a reduced energy. An impulse

turbine operates under atmospheric pressure, there is no change of static

pressure across the turbine runner and the unit is often referred to as a free

jet turbine. Important impulse turbines are: Pelton wheel, Turgo-impulse wheel,

Girad turbine, Banki turbine and Jonval tur-bine etc., Pelton wheel is

predominantly used at present.

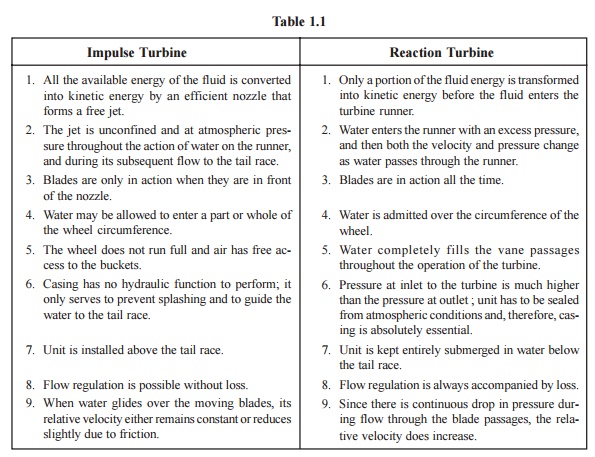

Reaction Turbine wherein a part of the total

available hydraulic energy is transformed into kinetic energy before the water is taken to the turbine runner. A

substantial part remains in the form of pressure energy. Subsequently both the

velocity and pressure change simultaneously as water glides along the turbine

runner. The flow from inlet to outlet of the turbine is under pressure and,

therefore, blades of a reaction turbine are closed passages sealed from

atmospheric conditions.

Fig. 1.17 illustrates

the working principle of a reaction turbine in which water from the reservoir

is taken to the hollow disc through a hollow shaft. The disc has four radial

openings, through tubes, which are shaped as nozzles. When the water escapes

through these tubes its pressure energy decreases and there is increase in

kinetic energy relative to the rotating disc. The resulting reaction force sets

the disc in rotation. The disc and shaft rotate in a direction opposite to the

direction of water jet. Important reaction turbines are, Fourneyron, Thomson,

Francis, Kaplan and Propellor turbines Francis and Kaplan turbines are widely

used at present.

The following table

lists salient points of difference between the impulse and reaction turbines

with regard to their operation and application.

Impulse Turbine

1.

All the available energy of the fluid is

converted into kinetic energy by an efficient nozzle that forms a free jet.

2.

The jet is unconfined and at atmospheric

pressure throughout the action of water on the runner, and during its

subsequent flow to the tail race.

3.

Blades are only in action when they are

in front of the nozzle.

4.

Water may be allowed to enter a part or

whole of the wheel circumference.

5.

The wheel does not run full and air has

free access to the buckets.

6.

Casing has no hydraulic function to

perform; it only serves to prevent splashing and to guide the water to the tail

race.

7.

Unit is installed above the tail race.

8.

Flow regulation is possible without

loss.

9.

When water glides over the moving

blades, its relative velocity either remains constant or reduces slightly due

to friction.

Reaction Turbine

1.

Only a portion of the fluid energy is

transformed into kinetic energy before the fluid enters the turbine runner.

2.

Water enters the runner with an excess

pressure, and then both the velocity and pressure change as water passes

through the runner.

3.

Blades are in action all the time.

4.

Water is admitted over the circumference

of the wheel.

5.

Water completely fills the vane passages

throughout the operation of the turbine.

6.

Pressure at inlet to the turbine is much

higher than the pressure at outlet ; unit has to be sealed from atmospheric

conditions and, therefore, casing is absolutely essential.

7.

Unit is kept entirely submerged in water

below the tail race.

8.

Flow regulation is always accompanied by

loss.

9.

Since there is continuous drop in

pressure during flow through the blade passages, the relative velocity does

increase.

Related Topics