Chapter: Electric Energy Generation and Utilisation and Conservation : Wind Energy

Structure and components of wind mill

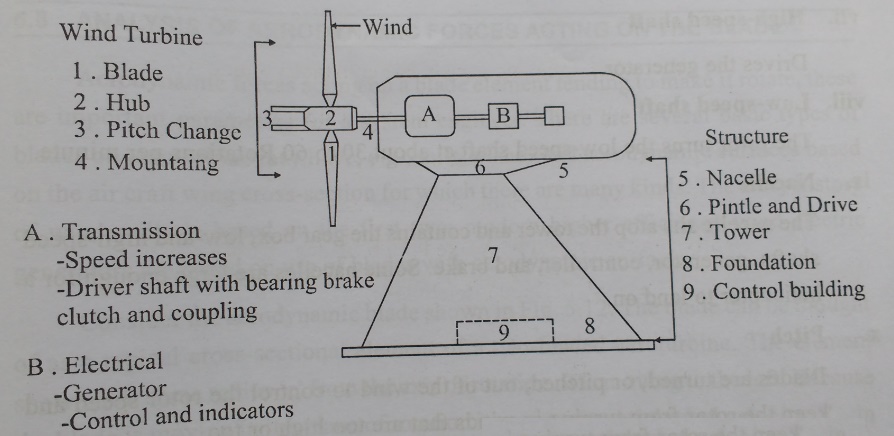

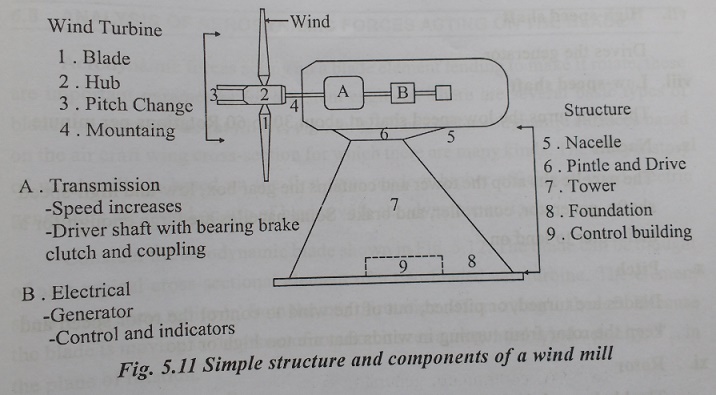

Structure and

components of wind mill

The

simple structure of horizontal axis wind turbine (wind mill) shown in fig.5.11.

The

following components are used in a wind mill.

(1) Anemometer

Measure

the wind speed and transmits wind speed data to the controller

(2) Blades

Most

turbines have either two or three blades. Wind blowing over the blades causes

the blades to “lift” and rotate.

(3) Brake

A

disc brake, which can be applied mechanically, electrically, or hydraulically

to stop the rotor in emergencies.

(4) Controller

The

controller starts up the machine at wind speeds of about 8 to 16 miles per hour

(mph) and shuts off the machine at about 55 mph. Turbines do not operate at

wind speeds above about 55 mph because they might be damaged by the high winds.

(5) Gear box

Gear

connect the low-speed shaft to the high speed shaft and increase rotational

speeds from about 30 to 60 rotations per minute (rpm) to about 1000 to 1800

rpm, the rotational speed required by most generators to produce electricity.

The gear box is a costly (and heavy) part of the wind turbine and engineers are

exploting “direct-drive” generators that operate at lower rotational speeds and

don’t need gear boxes.

(6) Generator

Usually

an off-the-shelf induction generator that produces 60-cyclic AC electricity.

(7) High

speed shaft

Drives

the generator.

(8) Low-speed

shaft

The

rotor turns the low-speed shaft 30 to 60 rotations per minute.

(9) Nacelle

The

nacelle sits the lower and contains the gear box, low-and high-speed shafts,

generator, controller, and brake. Some nacelle are large enough for a

helicopter to land on.

(10) Pitch

Blades

are turned, or pitched, out of the wind to control the rotor speed and keep the

rotor form turning in winds that are too high or too.

(11) Rotor

The

blades and the hub together are called the rotor.

(12) Tower

Towers

are made from tubular steel (shown here), concrete, or steel lattice. Because

wind speed increases with height, taller towers enable turbines to capture more

energy and generate more electricity.

(13) Wind direction

This

is an “upwind” turbine, so called because it operates facing into the wind.

Other turbines are designed to run “downwind”, facing away from the wind.

(14) Wind vane

Measure

wind direction and communicates with the yaw drive to orient the turbine

properly with respect to the wind.

(15) Yaw drive

Upwind

turbines face into the wind, the yaw drive is used to keep the rotor facing

into the wind as the wind direction changes. Downwind turbines don’t require a

yaw drive, the wind blows the rotor downwind.

(16) Yaw motor

Powers

the yaw drive.

Related Topics