Chapter: Electric Energy Generation and Utilisation and Conservation : Wind Energy

Performance of Wind Machines

PERFORMANCE OF

WIND MACHINES

WECS

efficiency is of interest to both aerogenerator designers and system engineers.

As WECS is a capital intensive technology, it is desirable for the overall wind

electric plant to have the highest efficiency possible, thus optimally

utilizing capital resources and minimizing the busbar electric energy cost.

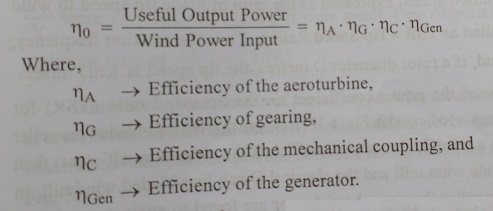

The

overall conversion efficiency, µoof an aerogenerator of the general

type is

Above

equation shows an application of cascaded energy conversion, from which overall

efficiency will be strongly determined by the lowest efficiency converter in

the cascade. For the aerogenerator this is the aeroturbine; the efficiency of

the remaining three elements can be made quite high but less than 100 percent.

It is now evident why so much emphasis is placed on the efficiency of the

aeroturbine in wind literature.

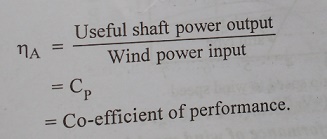

Consider

an arbitrary aeroturbine (Here Aero turbine is not equal to aerogenerator) of

cross-sectional area ‘A’ driven by the wind. Its efficiency would be:

Thus

the coefficient of performance of an aeroturbine is the fraction of power in

the wind through the swept area which is converted into useful mechanical shaft

power. The coefficient of performance is widely utilized throughout the recent

wind research. We have seen that Cp for horizontal axis wind machine

has theoretical maximum value = 0.593.

This

theoretical efficiency limitation on a wind energy conversion system is loosely

analogical similar to the thermodynamic carnot efficiency limitation on a

conventional thermal power plant.

We

know that the convertible power of energy is proportional to the cube of the

wind speed. Thus if the wind speed decreases by 20%, the power output is

reduced by almost 50%. The wind speed may very considerable from day to day and

from season to season. The efficiency of a wind generator depends on the design

of an wind rotor and rotational speed, expressed as the ratio of blade tip

speed to wind speed i.e., VT/V (is called as TSR – Tip Speed Ratio),

if n is the rotation frequency, ie., rotation per second, if a rotor diameter D

meters, the tip speed is πnD m/sec.

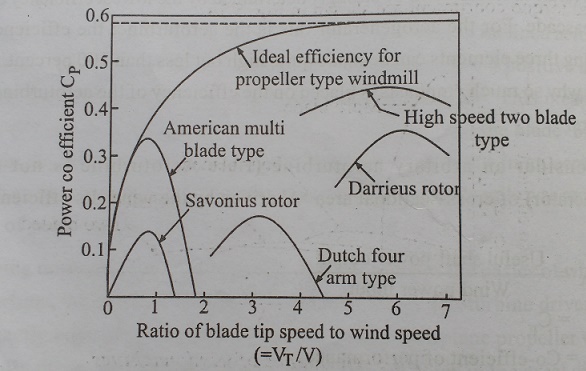

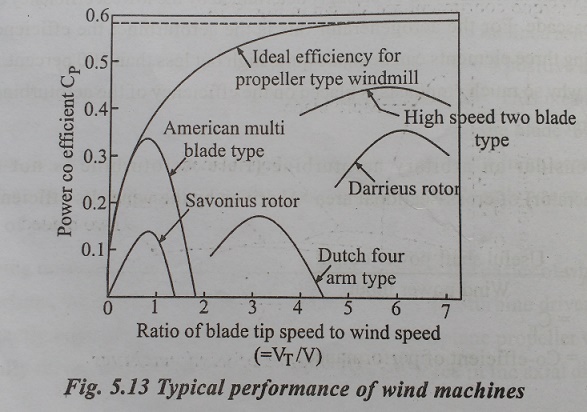

The

dependence of the power coefficient on the tip speed ratio (TSR)

for some common rotor types is indicated in Fig. 5.13. It is seen that the

two-bladed propeller type of rotor can attain a much higher power coefficient

(i.e., it is more efficient) than the American multi-blade wind mill and the

classical Dutch four-bladed windmill. In practice two-bladed propeller

(horizontal axis) rotor are ound to attain a maximum power coefficient of 0.40

to 0.45 at a tip speed ratio in the range a roughly 6 to 10

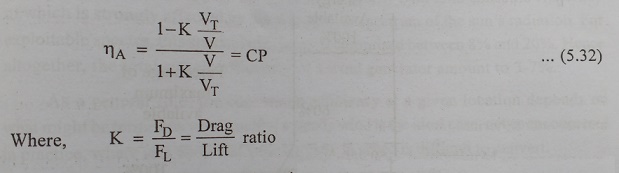

Golding

has derived the expression for aeroturbine efficiency as,

Clearly

If there were no drag, i.e., K=0, then efficiency would be unity (μA=1).

In actuality K can be made very small, depending on the airfoil choosen and the

angle of attack. Also above equation tells us the efficiency would be low if VT/V

were very large or again If it were small. One suspicions that there exists an

optimum ratio of VT/V (i.e., TSR).

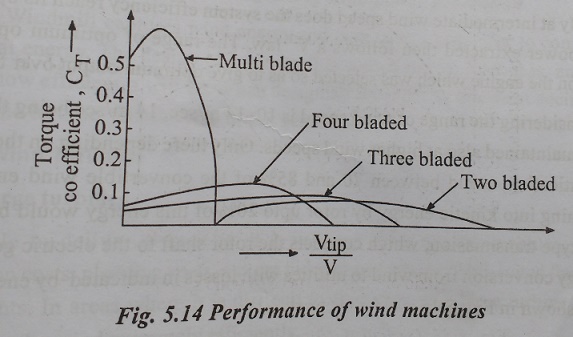

If

one assembles models of various types of aeroturbine blades and puts them in a

wind tunnel and runs carefully controlled experiments of their efficiencies as

function of their TSR’S, then one obtains a family of curves similar to that

shown in Fig.5.14.

The

various types of windmills performance characteristics with respect to TSR and

torque coefficient are shown in Fig. 5.14.

Only

at intermediate wind speed does the system efficiency reach its optimum and the

power extracted then follows a V3 law. The range of optimum

operation depends on the engine which was selected so as to give optimum output

over the year.

Considering

the range of wind speed is 10-14m/sec, 14m/sec being the rated velocity

maintained also at higher wind speeds. Only there depending on the degree of

sophistication, could between 70 and 85% of the convertible wind energy by the

gear type transmission, which connects the rotor shaft to the electric

generator. The energy conversion from wind to utilities with losses in

indicated by energy flow diagram shown in Fig. 5.15.

Related Topics