Chapter: Mechanical : Automobile Engineering : Transmission Systems

Semi Automatic Transmission

Semi Automatic Transmission

A semi-automatic transmission (also known as clutch less

manual transmission, automated manual transmission, e-gear, shift-tronic,

flappy paddle gearbox, or paddle shift gearbox) is a system which uses

electronic sensors, processors and actuators to do gear shifts on the command

of the driver. This removes the need for a clutch pedal which the driver

otherwise needs to depress before making a gear change, since the clutch itself

is actuated by electronic equipment which can synchronize the timing and torque

required to make gear shifts quick and smooth.

The system was designed by European automobile manufacturers

to provide a better driving experience, especially in cities where congestion

frequently causes stop-and-go traffic patterns. Like a tiptronic transmission,

a semi-automatic transmission can also be switched to manual mode to perform

gear shifting at the drivers wish.

The

two most common semi-automatic transmissions

·

Direct shift transmission (or dual-clutch

transmission)

·

Electro-hydraulic manual transmission (or

sequential transmission)

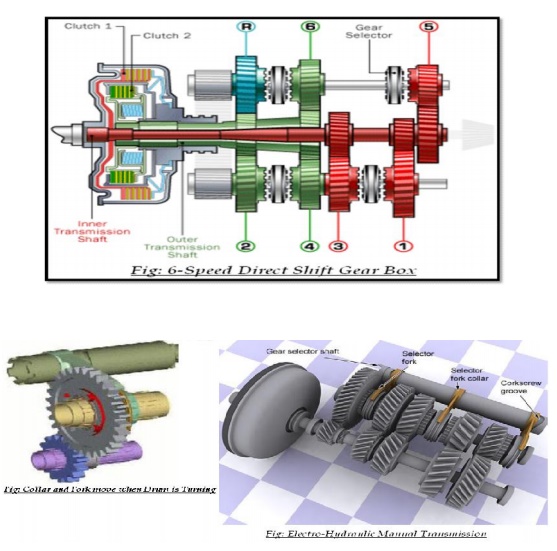

Direct shift transmission: In direct shift transmission direct

shift gear box is used. The Direct-Shift Gearbox or D.S.G. is an electronically

controlled, twin-shaft dual-clutch manual gearbox, without a conventional

clutch pedal, with full automatic or semi-manual control.

Unlike the conventional manual transmission system, there are

two different gear/collar sets, with each connected to two different

input/output shafts. The outer clutch pack drives gears 1, 3, 5 and reverse. It

is just like two conventional manual transmission gear boxes in one. The inner

clutch pack drives gears 2, 4, and 6. Instead of a standard large dry

single-plate clutch, each clutch pack is a collection of four small wet

interleaved clutch plates.

Due

to space constraints, the two clutch assemblies are concentric. To

automatically shift

from 1st

gear to 2nd gear, first the computer detects that the spinning speed of the

input shaft is too high, and engages the 2nd gear’s collar

to the 2nd gear. The clutch then disengages from 1st gear’s input shaft, and

engages the 2nd gear’s input shaft. Controlled by computer, the gear shift

becomes

extremely fast compared with a

conventional manual transmission.

Using

direct contact of the clutch instead of fluid coupling also improves power

transmission

efficiency. Another advanced technology used

for direct shift trans-mission allows it to perform

“double clutching” by shifting the gear to neutral

first, adjusting the spinning speed of the input shaft, and then shifting

to the next gear. This makes gear shifting very smooth.

Operation Modes Of D.S.G.:- "D" mode:

When the motor vehicle is stationary, in neutral, both clutch

packs are fully disengaged. When the driver has selected D for drive (after

pressing the foot brake pedal), the transmission's first gear is selected on the

first shaft, and the clutch prepares to engage. At the same time, the second

gear is also selected, but the clutch pack for second gear remains fully

disengaged. When the driver releases the brake pedal, the clutch pack for the

first gear takes up the drive, and the vehicle moves forward. Pressing the

accelerator pedal increases forward speed. As the car accelerates, the

transmission's computer determines when the second gear (which is connected to

the second clutch) should be fully utilized.

Depending on the vehicle speed and amount of power being

requested by the driver (full throttle or part-throttle normal driving), the

D.S.G. then up-shifts. During this sequence, the DSG disengages the first

clutch while engaging the second clutch (all power from the engine is now going

through the second shaft), thus completing the shift sequence. This sequence

happens in 8 ms, and there is practically no power loss.

Once the vehicle has shifted up to second gear, the first gear

is immediately de-selected, and third gear (being on the same shaft as 1st and

5th) is pre-selected, and is pending. Once the time comes to shift, the second

clutch disengages and the first clutch re-engages. This method of operation

continues in the same manner up to 6th gear.Downshifting is similar to

up-shifting but in reverse order. The car's computer senses the car slowing

down or more power required, and thus lines up a lower gear on one of the

shafts not in use, and then completes the downshift.

The actual shift timings are determined by the D.S.G.'s

Electronic Control Unit, or E.C.U., which commands a hydro-mechanical unit, and

the two units combined are called a "mechatronics" unit. Because the

D.S.G. & E.C.U. uses "fuzzy logic", the operation of the DSG is

said to be "adaptive"; i.e. the DSG will "learn" how the

user drives the car, and will tailor the shift points accordingly.

In the vehicle instrument display, between the speedometer and

tachometer, the available shift positions are shown, the current position of

the shift lever is highlighted, and the current gear ratio is also displayed as

a number. Under "normal", progressive acceleration and deceleration,

the DSG shifts in a "sequential" mode, i.e. under acceleration: 1

> 2 > 3 > 4 > 5 > 6, and the same sequence reversed for

deceleration. However, if the car is being driven at sedate speeds, with a

light throttle opening, and the accelerator pedal is then pressed fully to the

floor, this activates the "kick-down" function. During kick-down, the

DSG can skip gears, going from 6th gear straight down to 3rd gear.

"S" mode:

The floor selector lever also has an S position. When S is

selected, "sport" mode is activated in the DSG. Sport mode still

functions as a fully automatic mode, identical in operation to "D"

mode, but up-shifts and down-shifts are made much higher up the engine

rev-range. This aids a sportier driving manner, by utilizing considerably more

of the available engine power, and also maximizing engine braking. However,

this mode does have a worsening effect on the vehicle fuel consumption, when

compared to D mode. S is also highlighted in the instrument display, and like D

mode, the currently used gear ratio is displayed as a number.

Manual (Tiptronic) Mode:

Additionally, the floor shift lever also has another plane of

operation, for manual or tiptronic mode, with spring-loaded "+" and

"−"

positions. This plane is selected by moving the stick away

from the

driver (in vehicles with the drivers seat on the right, the lever is pushed to

the left, and in left-hand drive cars, the stick is pushed to the right) when

in "D" mode only. When this plane is selected, the D.S.G. can now be

controlled like a manual gearbox, even though under a sequential shift pattern.

The readout in the instrument display changes to 6 -5- 4- 3-

2- 1, and just like the automatic modes, the currently used gear ratio is

highlighted. To change up a gear, the lever is pushed forwards (against a

spring pressure) towards the "+", and to change down, the lever is

pulled rearwards towards the "−".

The DSG box can now be operated with the gear changes being

(primarily) determined by the driver. This method of operation is commonly

called "tiptronic". When accelerating in Manual/tiptronic mode, the

D.S.G. will still automatically change up just before the red-line and when

decelerating, it will change down automatically at very low revs, just before

the engine idle speed (tick over). Furthermore, if the driver calls for a gear

when it is not appropriate (i.e., engine speed near the red-line, and a down

change is requested) the D.S.G. will delay the change until the engine revs are

at an appropriate level to cope with the requested gear.

Paddle Shifters:

On certain "sporty” or high-powered

cars paddle shifters are available. The paddle shifters

have

two distinct advantages: the driver can safely keep both hands on the steering

wheel when using the Manual/tiptronic mode; and the driver can immediately

manually override either of the automatic programs (D or S) on a temporary

basis, and gain instant manual control of the D.S.G. box.

If the manual override of one of the automatic programs (D or

S) is utilized intermittently, the gearbox will "default" back to the

previously selected automatic mode after a predetermined duration of inactivity

of the paddles, or when the car becomes stationary. Alternatively, should the

driver wish to revert immediately to automatic control, this can be done by

holding the "+" paddle for at least two seconds.

Electro Hydraulic Manual

Transmission:

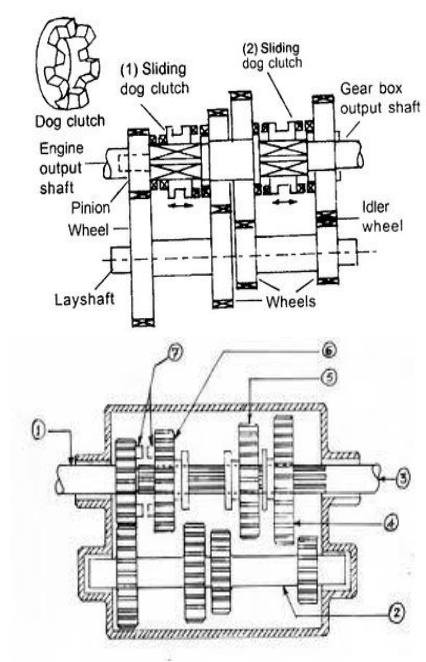

In

electro-hydraulic manual transmission (also known as sequential transmission)

the gear set

is almost

the same as the conventional transmission system, except that the shifting of

the se-lector is not an “H” pattern. Instead, all selector forks

are connected to a drum. The drum has several

grooves,

and each has a ball sliding in it. Each fork hooks up to a ball and can be

moved forward and backward when the drum is turning. Based on the pattern of

the grooves on the drum, by turning the drum, each fork can move forward and

backward in turn, which makes gear selection sequential.

Therefore,

it is impossible for an electro-hydraulic manual transmission to perform a gear

shift from 1st to 3rd or 4th to 2nd. The shifting must be sequential, like 1st ▬►

2nd ▬► 3rd ▬►4th, or

4th▬►3rd▬►2nd▬►1st.

Related Topics