Chapter: Mechanical : Automobile Engineering : Transmission Systems

Differential Unit

Differential Unit:

Differentials are a variety of gearbox, almost always used in

one of two ways. In one of these, it receives one input and provides two

outputs; this is found in every automobile. In automobile and other wheeled

vehicles, the differential allows each of the driving wheels to rotate at

different speeds, while supplying equal torque to each of them. In the other,

less commonly encountered, it combines two inputs to create an output that is

the sum (or difference) of the inputs. In automotive applications, the differential

and its housing are sometimes collectively called a "pumpkin"

(because the housing resembles a pumpkin).

Purpose:-

The

differential gear box has following functions:

·

Avoid skidding of the rear wheels on a road

turning.

·

Reduces the speed of inner wheels and increases

the speed of outer wheels, while drawing a curve.

·

Keeps equal speeds of all the wheels while moving

on a straight road.

·

Eliminates a single rigid rear axle, and provides

a coupling between two rear axles.

The following description of a differential applies to a

"traditional" rear- or front-wheel-drive car or truck:

Power is supplied from the engine, via the transmission or

gearbox, to a drive shaft termed as propeller shaft, which runs to the

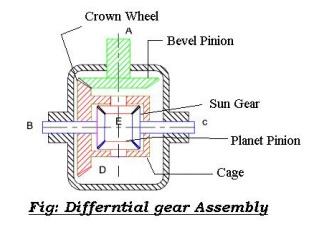

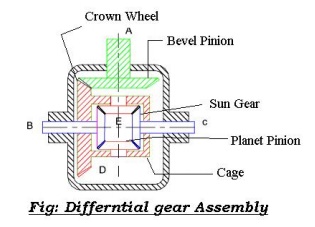

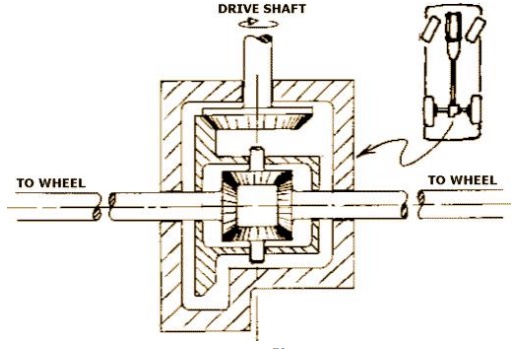

differential. A spiral bevel pinion gear at the end of the propeller shaft is

encased within the differential itself, and it meshes with the large spiral

bevel ring gear termed as crown wheel. The ring and pinion may mesh in hypoid

orientation.

The ring gear is attached to a carrier, which holds what is

sometimes called a spider, a cluster of four bevel gears in a rectangle, so

each bevel gear meshes with two neighbors and rotates counter to the third that

it faces and does not mesh with. Two of these spider gears are aligned on the

same axis as the ring gear and drive the half shafts connected to the vehicle's

driven wheels.

These are called the side gears. The other two spider gears

are aligned on a perpendicular axis which changes orientation with the ring

gear's rotation. These two gears are just called pinion gears, not to be

confused with the main pinion gear. (Other spider designs employ different

numbers of pinion gears depending on durability requirements.)

As the carrier rotates, the changing axis orientation of the

pinion gears imparts the motion of the ring gear to the motion of the side

gears by pushing on them rather than turning against them (that is, the same

teeth stay in contact), but because the spider gears are not restricted from

turning against each other, within that motion the side gears can counter-rotate

relative to the ring gear and to each other under the same force (in which case

the same teeth do not stay in contact).

Thus, for example, if the car is making a turn to the right,

the main ring gear may make 10 full rotations. During that time, the left wheel

will make more rotations because it has further to travel, and the right wheel

will make fewer rotations as it has less distance to travel. The side gears

will rotate in opposite directions relative to the ring gear by, say, 2 full

turns each (4 full turns relative to each other), resulting in the left wheel

making 12 rotations, and the right wheel making 8 rotations.

The rotation of the ring gear is always the average of the

rotations of the side gears. This is why if the wheels are lifted off the

ground with the engine off, and the drive shaft is held (preventing the ring

gear from turning inside the differential), manually rotating one wheel causes

the other to rotate in the opposite direction by the same amount.

When the vehicle is traveling in a straight line, there will

be no differential movement of the planetary system of gears other than the

minute movements necessary to compensate for slight differences in wheel

diameter, undulations in the road (which make for a longer or shorter wheel

path), etc.

Related Topics