Chapter: Mechanical : Automobile Engineering : Transmission Systems

Clutch

Clutch

Clutch is a device which is used in the transmission system of

automobile to engage and disengage the engine to the transmission or gear box.

It is located between the transmission and the engine. When the clutch is

engaged, the power flows from the engine to the rear wheels in a

rear-wheel-drive transmission and the vehicle moves. When the clutch is

disengaged, the power is not transmitted from the engine to the rear wheels and

vehicle stops even if engine is running.

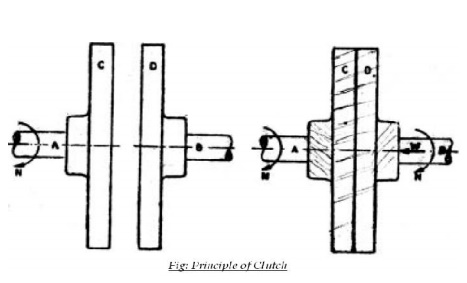

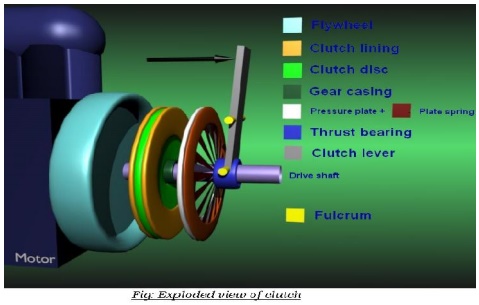

It works on the principle of friction. When two friction

surfaces are brought in contact with each other and they are united due to the

friction between them. If one is revolved the other will also revolve.

The friction depends upon the surface area contact. The

friction surfaces are so designed that the driven member initially slips on

driving member when initially pressure is applied. As pressure increases the

driven member is brought gradually to speed the driving member.

The three main parts of clutch

are:

·

Driving member

·

Driven member

·

Operating member

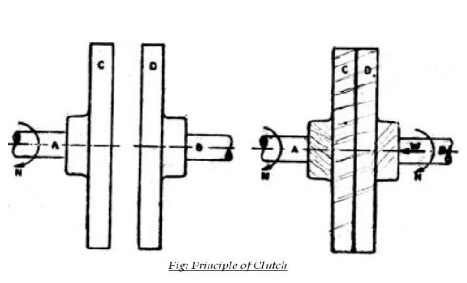

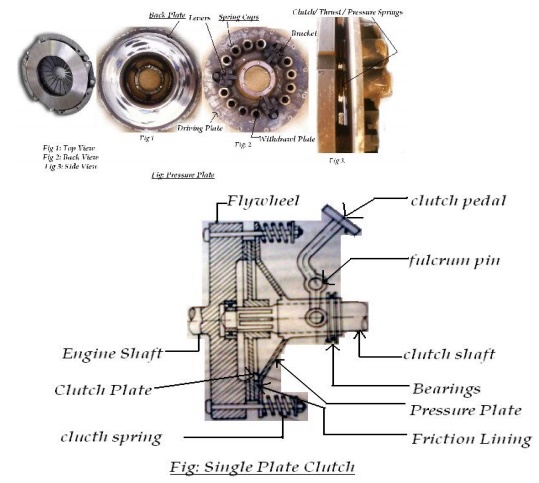

The driving member consists of a flywheel mounted on the

engine crank shaft. The flywheel is bolted to cover which carries a pressure

plate or driving disc, pressure springs and releasing levers. Thus the entire

assembly of flywheel and cover rotates all the times. The clutch housing and

the cover provided with openings dissipate the heat generated by friction

during the clutch operation.

The driving member consists of a disc or plate called clutch

plate. It is free to slide length wise on the splines of the clutch shaft. It

carries friction materials on both of its surfaces when it is gripped between

the flywheel and the pressure plate; it rotates the clutch shaft through

splines.

The operating members consists of a foot pedal, linkage,

release or throw-out bearing, release levers and springs necessary to ensure

the proper operation of the clutch.

Now the driving member in an automobile is flywheel mounted on

crank shaft, the driven member is the pressure plate mounted on transmission or

gear box input shaft. Friction surfaces or clutch plates is placed between two

members.

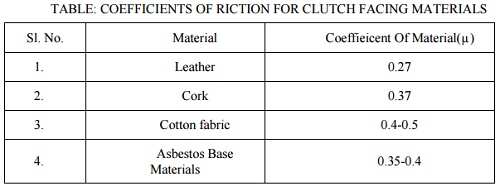

Types of Friction Materials:

The

friction materials of the clutch plate are generally of 3 types:

·

Mill Board Type

·

Molded type

·

Woven type

Mill Board type friction materials mainly include asbestos

material with different types of impregnates.

Molded type friction materials are made from a matrix of

asbestos fiber and starch or any other suitable binding materials. They are

then heated to a certain temperature for moulding in dies under pressure. They

are also made into sheets by rolling, pressing and backs till they are

extremely hard and dense. Metallic wires are used sometimes to increase wear

properties.

Woven types facing materials are made

by impregnating a cloth with certain binders or by weaving threads of copper or

brass wires covered with long fiber asbestos and cotton. The woven sheets

treated with binding solution are baked and rolled.

Properties

Of Good Clutching:

·

Good Wearing Properties

·

High Resistance to heat

·

High coefficient of friction

·

Good Binders in it

Operation

Of Clutch:

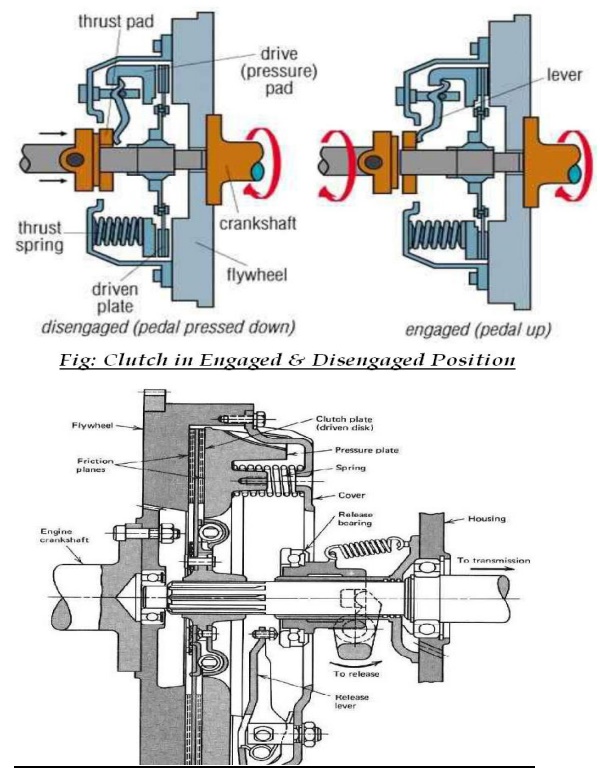

When the clutch pedal is pressed

through pedal movement, the clutch release bearing presses on the clutch

release lever plate which being connected to clutch release levers, forces

these levers forward. This causes the pressure plate to compress pressure springs,

thus allowing it to move away from the clutch driven plate. This action

releases the pressure on the driven plate and flywheel, the flywheel is now

free to turn independently, without turning the transmission.

When the clutch pedal is released, reverse action takes place

i.e. the driven plate is again forced against the flywheel by the pressure

plate- because of the force exerted by pressure springs. The pressure plate

will keep on pressing the facings of driven plate until friction created

becomes equal to the resistance of the vehicle. Any further increase in

pressure will cause the clutch plate and the transmission shaft to turn along

with flywheel, thus achieving vehicle movement.

1.Single Clutch Plate:

It is the most common type of clutch plate used in motor

vehicles. Basically it consists of only one clutch plate, mounted on the

splines of the clutch plate. The flywheel is mounted on engine crankshaft and

rotates with it. The pressure plate is bolted to the flywheel through clutch

springs, and is free to slide on the clutch shaft when the clutch pedal is

operated. When the clutch is engaged the clutch plate is gripped between the

flywheel and pressure plate. The friction linings are on both the sides of the

clutch plate. Due to the friction between the flywheel, clutch plate and the

pressure plate the clutch plate revolves the flywheel. As the clutch plate

revolves the clutch shaft also revolves. Clutch shaft is connected to the

transmission gear box. Thus the engine power is transmitted to the crankshaft

and then to the clutch shaft.

When the clutch pedal is pressed, the pressure plate moves

back against the force of the springs, and the clutch plate becomes free

between the flywheel and the pressure plate. Thus the flywheel remains rotating

as long as the engine is running and the clutch shaft speed reduces slowly and

finally it stops rotating. As soon as the clutch pedal is pressed, the clutch

is said to be engaged, otherwise it remains engaged due to the spring forces.

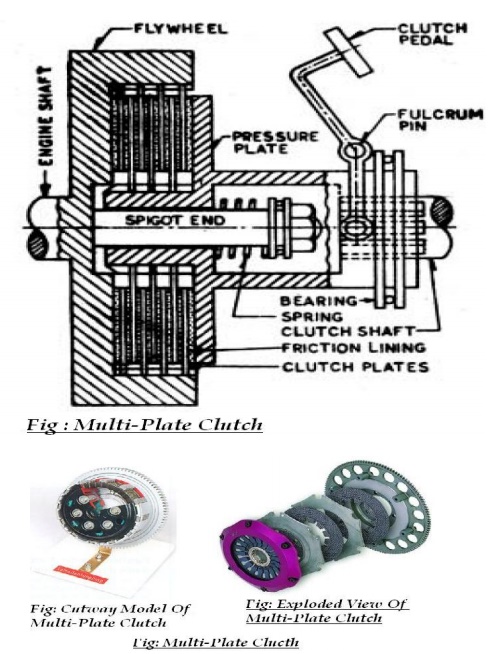

2.Multi-plate Clutch:

Multi-plate clutch consists of a number of clutch plates

instead of only one clutch plate as in case of single plate clutch. As The

number of clutch plates are increased, the friction surfaces also increases.

The increased number of friction surfaces obliviously increases the capacity of

the clutch to transmit torque.

The plates are alternately fitted to engine and gear box

shaft. They are firmly pressed by strong coil springs and assembled in a drum.

Each of the alternate plate slides on the grooves on the flywheel and the other

slides on splines on the pressure plate. Thus, each alternate plate has inner

and outer splines.

The multi-plate clutch works in the same way as a single plate

clutch by operating the clutch pedal. The multi-plate clutches are used in

heavy commercial vehicles, racing cars and motor cycles for transmitting high

torque. The multi-plate clutch may be dry or wet. When the clutch is operated

in an oil bath, it is called a wet clutch. When the clutch is operated dry it

is called dry clutch. The wet clutch is used in conjunction with or part of the

automatic transmission.

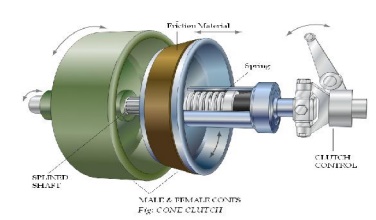

3.Cone Clutch:

Cone clutch consists of friction surfaces in the form of cone.

The engine shaft consists of female cone. The male cone is mounted on the

splined clutch shaft. It has friction surfaces on the conical portion. The male

cone can slide on the clutch shaft. Hen the clutch is engaged the friction

surfaces of the male cone are in contact with that of the female cone due to

force of the spring. When the clutch pedal is pressed, the male cone slides

against the spring force and the clutch is disengaged.

The only advantage of the cone clutch is that the normal force

acting on the friction surfaces is greater than the axial force, as compare to

the single plate clutch in which the normal force acting on the friction

surfaces is equal to the axial force. The disadvantage in cone clutch is that

if the angle of the cone is made smaller than 200 the male cone tends to bind

in the female cone and it becomes difficult to disengage the clutch. Cone

clutches are generally now only used in low peripheral speed applications

although they were once common in automobiles and other combustion engine

transmissions. They are usually now confined to very specialist transmissions

in racing, rallying, or in extreme off-road vehicles, although they are common

in power boats. Small cone clutches are used in synchronizer mechanisms in

manual transmissions.

4.Dog & Spline Clutch:

This type of clutch is used to lock two shafts together or to

lock a gear to shaft. It consists of a sleeve having two sets of internal

splines. It slides on a splined shaft with smallest diameter splines. The

bigger diameter splines match with the external dog clutch teeth on driving

shaft. When the sleeve is made to slide on the splined shaft, its teeth match

with the dog clutch teeth of the driving shaft. Thus the sleeve turns the

splined shaft with the driving shaft.

The clutch is said to be engaged. To disengage the clutch, the

sleeve is moved back on the splined shaft to have no contact with the driving

shaft. This type of clutch has no tendency to slip. The driven shaft revolves

exactly at the same speed of the driving shaft, as soon as the clutch is

engaged. This is also known as positive clutch.

5. Centrifugal Clutch:

The centrifugal clutch uses centrifugal forces, instead of

spring force for keeping it in engaged position. Also, it does not require

clutch pedal for operating the clutch. The clutch is operated automatically

depending on engine speed. The vehicle can be stopped in gear without stalling

the engine. Similarly the gear can be started in any gear by pressing the

accelerator pedal.

A centrifugal clutch works through centrifugal force. The

input of the clutch is connected to the engine crankshaft while the output

drives gear box shaft, chain, or belt. As engine R.P.M. increases, weighted

arms in the clutch swing outward and force the clutch to engage. The most

common types have friction pads or shoes radially mounted that engage the

inside of the rim of housing.

On the center shaft there are an assorted amount of extension

springs, which connect to a clutch shoe. When the center shaft spins fast

enough, the springs extend causing the clutch shoes to engage the friction

face. It can be compared to a drum brake in reverse. The weighted arms force

these disks together and engage the clutch.

When the engine reaches a certain RPM, the clutch activates,

working almost like a continuously variable transmission. As the load increases

the R.P.M. drops thereby disengaging the clutch and letting the rpm rise again

and reengaging the clutch. If tuned properly, the clutch will tend to keep the

engine at or near the torque peak of the engine.

These results in a fair bit of waste heat, but over a broad

range of speeds it is much more useful then a direct drive in many

applications. Weaker spring/heavier shoes will cause the clutch to engage at a

lower R.P.M. while a stronger spring/lighter shoes will cause the clutch to

engage at a higher R.P.M.

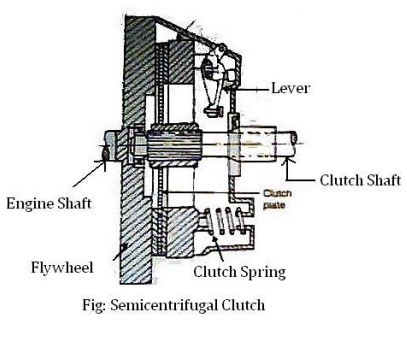

Semi-centrifugal Clutch:-

A semi centrifugal clutch is used to transmit power from high

powered engines and racing car engines where clutch disengagements requires

appreciable and tiresome drivers effort. The transmission of power in such

clutches is partly by clutch springs and rest by centrifugal action of an extra

weight provided in system. The clutch springs serve to transmit the torque up

to normal speeds, while the centrifugal force assists at speeds higher than

normal.

Besides

clutch, pressure plate and splines shaft it mainly consists of:

Compression

spring (3 numbers)

Weighted

levers (3 numbers)

At normal speeds when the power transmission is low the spring

keeps the clutch engaged, the weighted levers do not have any pressure on the

pressure plate. At high speed, when the power transmission is high the weights

fly off and levers exert pressure on the plate which keeps the clutch firmly

engaged. Thus instead of having more stiff springs for keeping the clutch

engaged firmly at high speeds, they are less stiff, so that the driver may not

get any strain in operating the clutch.

when the speed decreases, the weights fall and the levers do

not exert any pressure on the pressure plate. Only the spring pressure is

exerted on the pressure plate which is sufficient to keep the clutch engaged.

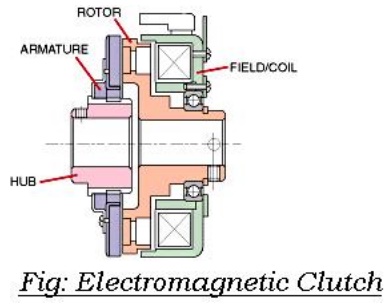

6. Electromagnetic Clutch:

An electromagnetic clutch is a clutch (a mechanism for

transmitting rotation) that is engaged and disengaged by an electromagnetic

actuator. In this type of clutch, the flywheel consists of winding. The current

is supplied to the winding from battery or dynamo.

When the current passes through the winding it produces an

electromagnetic field which attracts the pressure plate, thereby engaging the

clutch. When supply is cutoff, the clutch is disengaged. The gear lever

consists of a clutch release switch. When then the driver holds the gear lever

to change the gear the witch is operated cutting off the current to the winding

which causes the clutch disengaged. At low speeds when the dynamo output is

low, the clutch is not firmly engaged.

Therefore three springs are also provided on the pressure

plate which helps the clutch engaged firmly at low speed also. Cycling is

achieved by turning the voltage/current to the electromagnet on and off.

Slippage normally occurs only during acceleration. When the clutch is fully

engaged, there is no relative slip, assuming the clutch is sized properly, and

thus torque transfer is 100% efficient.

The electromagnetic clutch is most suitable for remote

operation since no linkages are required to control its engagement. It has

fast, smooth operation. However, because energy dissipates as heat in the

electromagnetic actuator every time the clutch is engaged, there is a risk of

overheating. Consequently the maximum operating temperature of the clutch is

limited by the temperature rating of the insulation of the electromagnet. This

is a major limitation. Another disadvantage is higher initial cost.

Related Topics