Chapter: Mechanical : Automobile Engineering : Transmission Systems

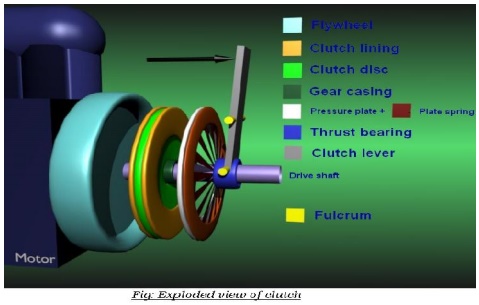

Three main parts of clutch

The three main parts of clutch are:

· Driving member

· Driven member

· Operating member

The driving member consists of a flywheel mounted on the engine crank shaft. The flywheel is bolted to cover which carries a pressure plate or driving disc, pressure springs and releasing levers. Thus the entire assembly of flywheel and cover rotates all the times. The clutch housing and the cover provided with openings dissipate the heat generated by friction during the clutch operation.

The driving member consists of a disc or plate called clutch plate. It is free to slide length wise on the splines of the clutch shaft. It carries friction materials on both of its surfaces when it is gripped between the flywheel and the pressure plate; it rotates the clutch shaft through splines.

The operating members consists of a foot pedal, linkage, release or throw-out bearing, release levers and springs necessary to ensure the proper operation of the clutch.

Now the driving member in an automobile is flywheel mounted on crank shaft, the driven member is the pressure plate mounted on transmission or gear box input shaft. Friction surfaces or clutch plates is placed between two members.

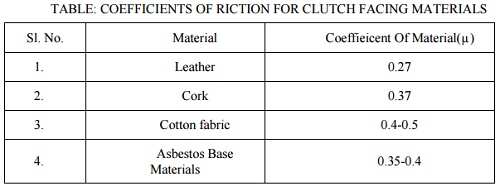

Types of Friction Materials:

The friction materials of the clutch plate are generally of 3 types:

· Mill Board Type

· Molded type

· Woven type

Mill Board type friction materials mainly include asbestos material with different types of impregnates.

Molded type friction materials are made from a matrix of asbestos fiber and starch or any other suitable binding materials. They are then heated to a certain temperature for moulding in dies under pressure. They are also made into sheets by rolling, pressing and backs till they are extremely hard and dense. Metallic wires are used sometimes to increase wear properties.

Woven types facing materials are made by impregnating a cloth with certain binders or by weaving threads of copper or brass wires covered with long fiber asbestos and cotton. The woven sheets treated with binding solution are baked and rolled.

Properties Of Good Clutching:

· Good Wearing Properties

· High Resistance to heat

· High coefficient of friction

· Good Binders in it

Related Topics