Chapter: Mechanical : Automobile Engineering : Transmission Systems

Gear Box: Principle of Gearing and Types of Gear Boxes

Gear Box

A gearbox is a mechanical method of transferring energy from

one device to another and is used to increase torque while reducing speed.

Torque is the power generated through the bending or twisting of a solid

material. This term is often used interchangeably with transmission.Located at

the junction point of a power shaft, the gearbox is often used to create a

right angle change in direction, as is seen in a rotary mower or a helicopter.

Each unit is made with a specific purpose in mind, and the gear ratio used is

designed to provide the level of force required. This ratio is fixed and cannot

be changed once the box is constructed. The only possible modification after

the fact is an adjustment that allows the shaft speed to increase, along with a

corresponding reduction in torque.In a situation where multiple speeds are

needed, a transmission with multiple gears can be used to increase torque while

slowing down the output speed. This design is commonly found in automobile

transmissions. The same principle can be used to create an overdrive gear that

increases output speed while decreasing torque.

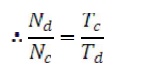

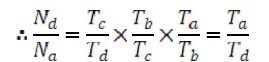

Principle Of Gearing

Consider a simple 4-gear train. It consists of a driving gear

A on input shaft and a driven gear D on the output shaft. In between the two

gears there are two intermediate gears B, C. Each of these gears are mounted on

separate shaft.We notice that:

Gear A drives Gear B

Gear C drives Gear D

Therefore, the over all speed ratios are:

1.Types of Gear Boxes:

The following types of gear box

are used in automobiles:

·

Sliding Mesh

·

Constant Mesh

·

Synchromesh.

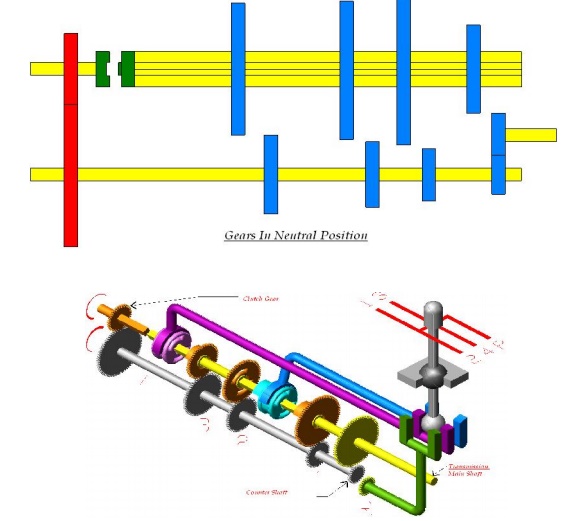

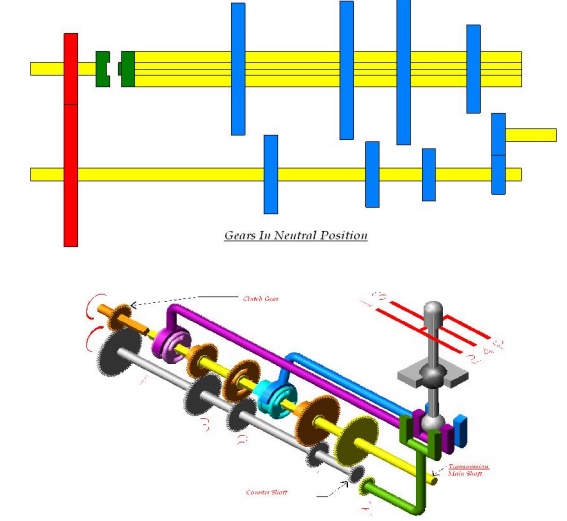

i. Sliding Mesh Gear Box

It

is the simplest gear box. The following figure shows 4-speed gear box in

neutral position.

4 gears

are connected to the lay shaft/counter shaft. A reverse idler gear is mounted

on another shaft and always remains connected to the reverse gear of

countershaft. This “H” shift pattern enables the

driver to select four different

gear ratios and a reverse gear.

Gears in Neutral:

When the engine is running and clutch is engaged the clutch

shaft gear drives the countershaft gear. The countershaft rotates opposite in

direction of the clutch shaft. In neutral position only the clutch shaft gear

is connected to the countershaft gear. Other gears are free and hence the

transmission main shaft is not turning. The vehicle is stationary.

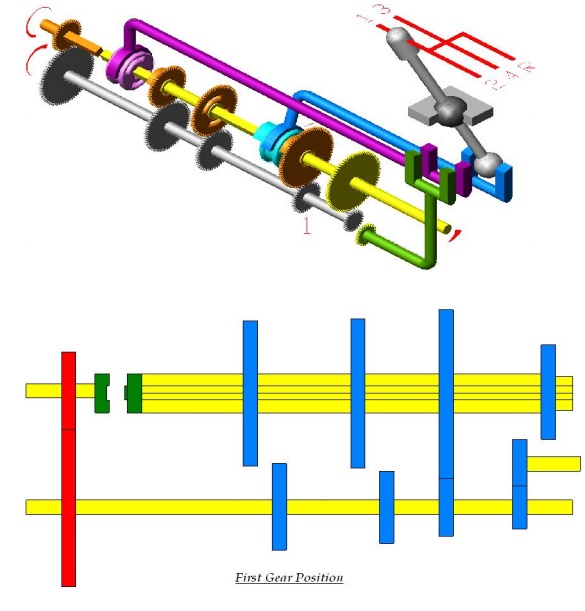

First or low shaft gear:

By operating the gear shift lever the larger gear on the main

shaft is moved along the shaft to mesh with the first gear of the counter

shaft. The main shaft turns in the same direction as that of the clutch shaft.

Since the smaller countershaft is engaged with larger shaft gear a gear

reduction of approximately 4:1 is obtained i.e. the clutch shaft turns 4 times

for each revolution of main shaft.

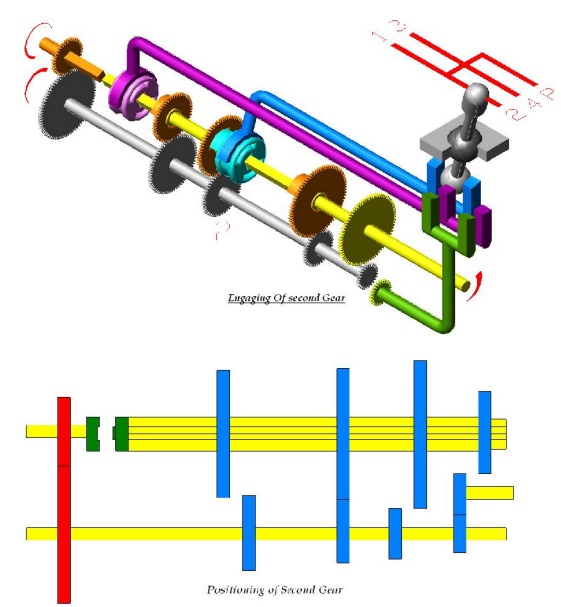

Second speed gear:

By operating the gear shift lever the third gear on the main

shaft is moved along the shaft to mesh with the third gear of the counter

shaft. The main shaft turns in same direction as clutch shaft. A gear reduction

of approximately 3:1is obtained.

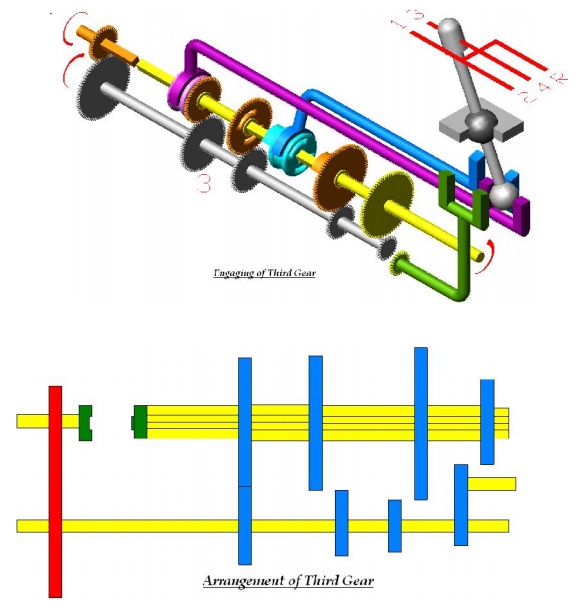

Third speed gear:

By operating the gear shift lever, the second gear of the main

shaft and countershaft are demeshed and then the third gear of the main shaft

are forced axially against the clutch shaft gear. External Teeth on the clutch

shaft gear mesh with the internal teeth in the third and top gear. The main

shaft turns in same direction as clutch shaft. A gear reduction of

approximately 2:1is obtained i.e. the clutch shaft turns 2 times for each

revolution of main shaft.

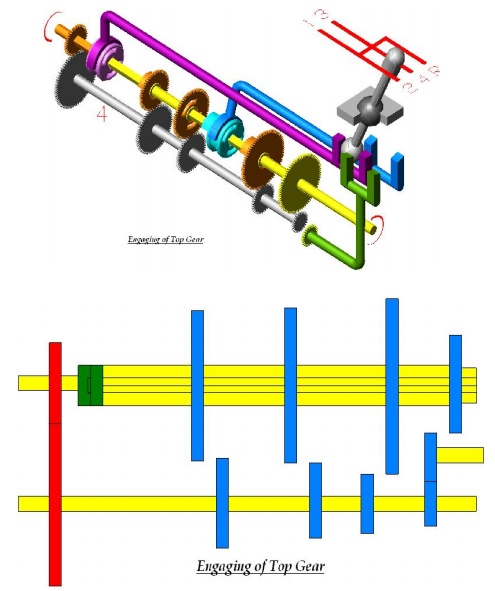

Fourth speed gear/ Top or

High-Speed Gear:

By operating the gear shaft lever the third gears of the main

and countershaft is demeshed and the gears present on the main shaft along with

the shaft is forced axially against the clutch shaft gear. External teeth

present on the main shaft engage with the internal teeth present on the main

shaft. The main shaft turns along with the clutch shaft and a gear ratio of

approximately 1:1 is obtained.

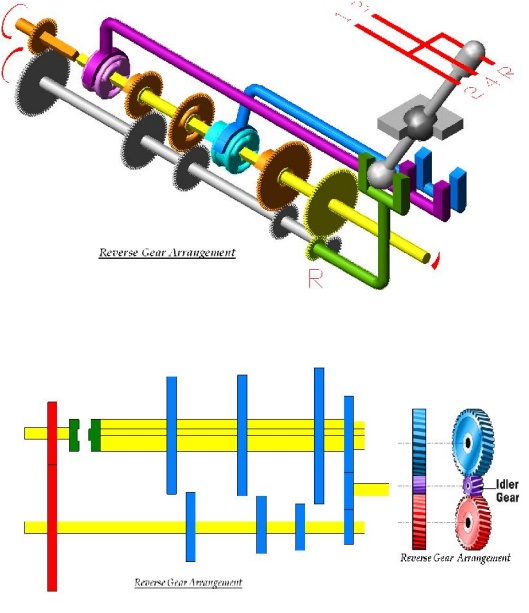

Reverse gear:

By operating the gear shift lever, the last gear present on

the main shaft is engaged with the reverse idler gear. The reverse idler gear

is always in mesh with the counters haft gear. Interposing the idler gear

between the counter-shaft reverse gear and main shaft gear, the main shaft

turns in the direction opposite to the clutch shaft. This reverses the rotation

of the wheels so that the wheel backs.

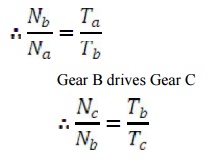

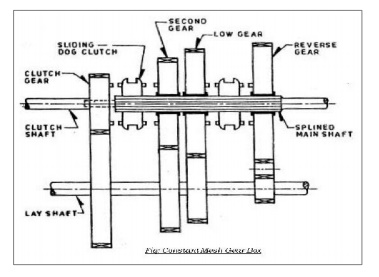

ii.Constant Mesh Gear Box:

In this type of gear box, all gears of the main shaft are in

constant mesh with the corresponding gears of the countershaft (Lay shaft). Two

dog clutches are provided on the main shaft- one between the clutch gear and

the second gear, and the other between the first gear and reverse gear. The

main shaft is splined and all the gears are free on it. Dog clutch can slide on

the shaft and rotates with it. All the gears on the countershaft are rigidly

fixed with it.

When the left hand dog clutch is made to slide to the left by

means of the gear shift lever, it meshes with the clutch gear and the top speed

gear is obtained. When the left hand dog clutch meshes with the second gear,

the second speed gear is obtained. Similarly by sliding the right hand dog

clutch to the left and right, the first speed gear and reverse gear are

obtained respectively. In this gear box because all the gears are in constant

mesh they are safe from being damaged and an unpleasant grinding sound does not

occur while engaging and disengaging them.

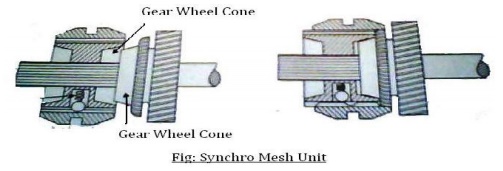

iii.Syncromesh Gear Box:

In sliding Mesh Gear box the two meshing gears need to be

revolve at equal peripheral speeds to achieve a jerk less engagement and it is

true for constant mesh gear box in which the peripheral speeds of sliding dog

and the corresponding gear on the output shaft must be equal. The

peripheral

speed is given byWhere d1 and N1 are pitch circle diameter and r.p.m. of gear

and d2 andN2 diameter and r.p.m. of attached dog respectively. Now N1 ≠

N2 since d1 ≠ d2 . Thus there is

a

difference in gear and dog which necessitates double declutching. The driver

has to disengage the clutch twice in quick succession therefore it is referred

as double declutching. There are two steps involved in this process:

The

clutch is disengaged i.e. first declutching and the gear system is placed in

its neutral

position.

Now the clutch is reengaged and acceleration pedal is pressed to adjust the

engine speed according to driver’s judgment.The clutch is

disengaged(i.e. second declutching) again the

appropriate gear is engaged and

then the clutch is reengaged

It is that gear box in which sliding synchronizing units are

provided in place of sliding dog clutches as in case of constant mesh gear box.

With the help of synchronizing unit, the speed of both the driving and driven

shafts is synchronized before they are clutched together through train of

gears. The arrangement of power flow for the various gears remains the same as

in constant mesh gear box. The synchronizer is made of frictional materials.

When the collar tries to mesh with the gear, the synchronizer will touch the

gear first and use friction force to drive the gear to spin at the same speed

as the collar. This will ensure that the collar is meshed into the gear very

smoothly without grinding.Synchromesh gear devices work on the principle that

two gears to be engaged are first bought into frictional contact which

equalizes their speed after which they are engaged readily and smoothly.

The following types of devices

are mostly used in vehicles:

·

Pin Type

·

Synchronizer ring type

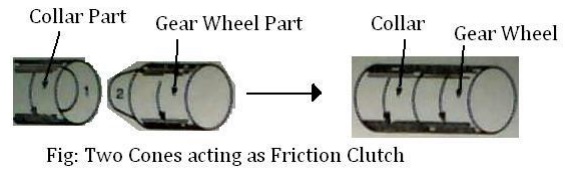

A synchronizing system is used for smooth meshing. Synchromesh

works like a friction clutch. In the following figure two conical surfaces

cone-1 is the part of the collar and the cone-2 is the part of the gear wheel.

Cone1, 2 are revolving at different speeds. While cone-2 is revolving, cone-1

gradually slides into it. Friction slows or speeds up the gear wheel. Finally

both the cones revolve at same speed.

revolving

at different speeds. The internal cone comes in contact with the outer cone of

the gear wheel. Friction slows or speeds up the gear wheel.

And when the collar and gear wheel rotate at same speed the

spring loaded outer ring of the collar is pushed forward. The dog slide

smoothly into mesh without clashing. The collar and gear wheel lock and revolve

at same speed. This the principle of synchromesh.

Related Topics