Chapter: Electric Energy Generation and Utilisation and Conservation : Industrial Heating and Welding

Resistance welding

Resistance welding:

In resistance welding heavy current is passed through the metal pieces to be welded. Heat will be developed by the resistance of the work piece to the flow of current.

The heat produced for welding is given by

H=I2Rt

Where,

H= Heat developed at the contact area.

I= Current in amperes.

R= Resistance in ohms.

t= time of flow of current.

i. Butt welding:

In this process heat is generated by the contact resistance between two components.

In this type of welding the metal parts to be joined end to end. Sufficient pressure is applied along the axial direction.

A heavy current is passed from the welding transformer which creates the necessary heat at the joint due to high resistance of the contact area.

Due to the pressure applied, the molten metal forced to produce a bulged joint.

This method is suitable for welding pipes, wires and rods.

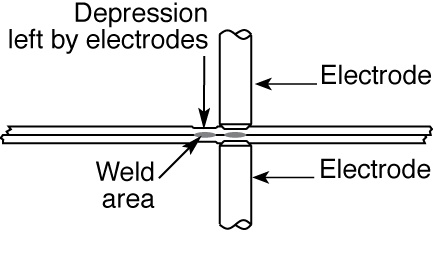

ii) Spot welding:

Spot welding is usually employed for joining or fabricating sheet metal structure. This type of joint only provides mechanical strength and is not air or water tight.

The plates to be welded are placed overlapping each other between two electrodes, sufficient mechanical pressure is applied through the electrodes.

The welding current flows through electrodes tips producing a spot weld. The welding current and period of current flow depend on the thickness of the plates.

Related Topics