Chapter: Electric Energy Generation and Utilisation and Conservation : Industrial Heating and Welding

Electric arc furnaces: Advantages, Application

Electric arc furnaces:

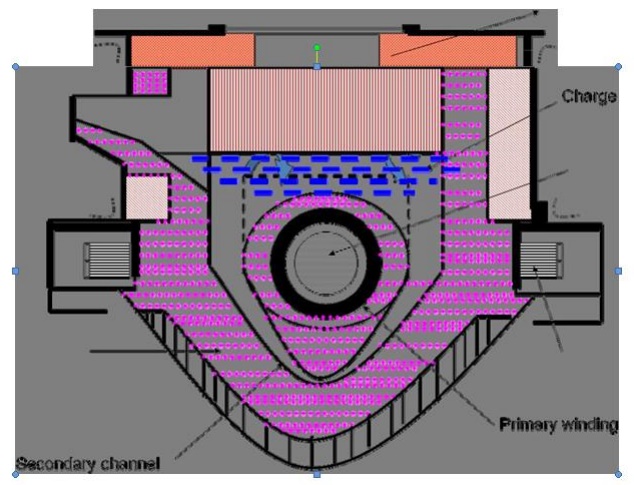

AJAX WYATT Vertical core type furnace:

The principle of operation is that of a transformer in which the secondary turns are replaced by a closed loop of molten metal. The primary winding is placed on the central limb of the core.

Hence leakage reactance is comparatively low and power factor is high. Inside of the furnace is lined with refactory depending upon the charge.

The top of the furnace is covered with an insulated cover which can be removed for charging. Necessary arrangements are usually made for titling the furnace to take out the molten metal.

The molten metal in the ‘V’ portion acts as a short circuited secondary. When primary is connected to the a.c supply, high current will be accumulated at the bottom and even a small amount of charge will keep the secondary completed.

Hence a chance of discontinuity of the circuit is less.

Advantages:

ü High efficiency and low operating cost.

ü Since both primary and secondary are on the same central core, its power factor is better.

ü The furnace is operated from the normal supply frequency.

ü Chances of discontinuity of the secondary circuit is less, hence it is useful for intermittent operations.

Applications:

ü This furnace is used for melting non ferrous metals like brass, zinc, tin, bronze, copper etc.

Related Topics