Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Track and Track Stresses

Requirements of a Good Railway Track

Requirements of a Good Railway Track

A permanent way or

track should provide a comfortable and safe ride at the maximum permissible

speed with minimum maintenance cost. To achieve these objectives, a sound

permanent way should have the following characteristics.

(a) The

gauge should be correct and uniform.

(b) The

rails should have perfect cross levels. In curves, the outer rail should have a

proper superelevation to take into account the centrifugal force.

(c) The

alignment should be straight and free of kinks. In the case of curves, a proper

transition should be provided between the straight track and the curve.

(d) The

gradient should be uniform and as gentle as possible. The change of gradient

should be followed by a proper vertical curve to provide a smooth ride.

(e) The

track should be resilient and elastic in order to absorb the shocks and

vibrations of running trains.

(f) The

track should have a good drainage system so that the stability of the track is

not affected by waterlogging.

(g) The

track should have good lateral strength so that it can maintain its stability

despite variations in temperature and other such factors.

(h) There

should be provisions for easy replacement and renewal of the various track

components.

(i) The

track should have such a structure that not only is its initial cost low, but

also its maintenance cost is minimum.

1 Track

Specifications on Indian Railways

Most of the railway lines on

Indian Railways are single lines, generally with a formation 6.10 m (20 ft)

wide for broad gauge and 4.8 m (16 ft) wide for metre gauge. The formation is

generally stable except in areas where clayey soil or other types of shrinkable

soils are found. Most of the track is straight except for 16% of the track on

BG and MG and 20% of the track on NG, which is on curves. The maximum degree of

curvature permissible is 10 o on the broad gauge, 16 o on the metre gauge, and

40 o on the narrow gauge.

The ballast used most often is

broken stone ballast, but in some areas, sand, moorum, and coal ash have also

been used. About a 20 cm to 30 cm (8" to 12") cushion of ballast is

normally provided below the sleepers to transfer the load evenly and to impart

the necessary resilience to the track.

The different materials used to

construct sleepers are wood (31%), cast iron (42%), and steel (27%). Experience

has shown that cast iron sleepers are not suitable for high-density routes.

Prestressed concrete sleepers have recently been developed by Indian Railways

and are proposed to be progressively laid on group A and B routes. Sleepers are

laid to various sleeper densities varying from (M + 7) to (M + 4)

or 1540 per km to 1310 per km depending upon the weight and volume of traffic.

Here M stands for length of rail in metres. (M + 7) means 20

sleepers per rail length for BG and 19 sleepers per rail length for MG.

The rails standardized for Indian

Railways are 60 kg and 52 kg for BG and 90 R, 75 R and 60 R, for MG (in 90 R,

75 R, etc., R stands for revised British specifications). Rails are normally

rolled in 13 m (42 ft) lengths for BG lines and 12 m (39 ft) lengths for MG

lines. The rails are welded together to form longer rails and are laid

progressively on the track in order to reduce maintenance costs and noise

levels and thereby provide more comfortable travel. The rails are welded in

depots in three rail panels, normally by the flash-butt welding method, to form

short welded rails (SWRs). Long welded rails (LWRs) are also being

progressively introduced on various routes of Indian Railways. Thermit welding

is normally done at the site to convert short welded rails into long welded

rails. The fastenings used are mostly screw and rail spikes, keys, etc. In

recent times, elastic fastenings such as elastic rail clips and IRN202 clips

have also been standardized on Indian Railways.

The turnouts used are normally 1

in 8 5 for goods trains and 1 in 12 as well as 1 in 16 for passenger trains. 1

in 20 turnouts were also designed sometime back for permitting higher speeds on

the turnout side, but these have since been discontinued. Curved switches and

thick web tongue rails have also been recently introduced to permit higher

speeds at turnouts.

2 Recommended Track Structure for BG and

MG Routes

Indian Railways (IR) has

modernized its track structure in the recent past to meet the challenges of

heavier loads and faster traffic. More than 10,000 km of the track is laid with

60-kg rails and more than 40,000 km is laid with concrete sleepers. The present

IR standards for BG and MG routes are elaborated in the following sections.

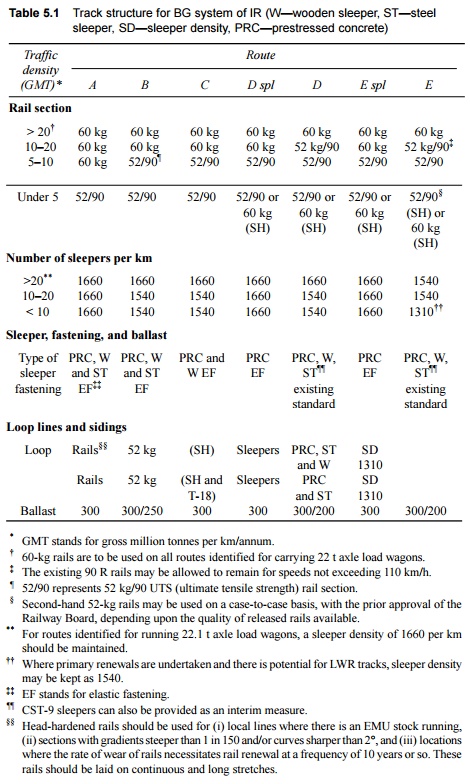

Track structure for BG routes

The track on Indian Railways for

BG sections is classified into five broad categories based on speed. These are

group A, B, C, D, and E routes. Also, D spl and E spl routes have been

subsequently added as explained in Section 1.8. The track standard on BG routes

has been reviewed and revised from time to time based on the obtainable speeds

and traffic conditions. The present BG track structure is detailed in Table

5.1.

Table

5.1 Track

structure for BG system of IR (W-wooden sleeper, ST-steel sleeper, SD-sleeper

density, PRC-prestressed concrete)

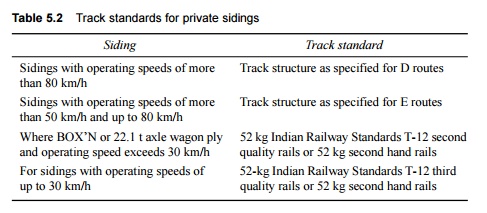

The

various track standards for private sidings are listed in Table 5.2

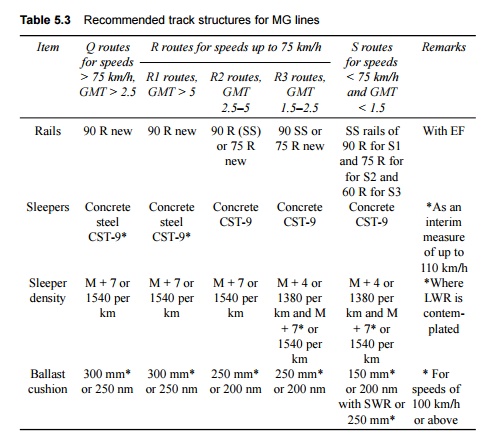

Track structure for MG routes

Tracks on MG routes have been

classified based on speed and GMT in categories Q, RI, R2, R3, and S routes.

The S route of MG has been further classified as S1, S2, and S3 routes as per

the details given below.

(a) Routes

with a through movement of freight traffic are identified as S1 routes.

(b) Uneconomic

branch lines are identified as S3 routes.

(c) Routes

that are neither S1 nor S3 are identified as S2 routes.

The track

standards being followed on MG routes are given in Table 5.3.

Table 5.3 Recommended track

structures for MG lines

The

following are MG track standard specifications.

(a) Heavy

haul routes identified for the movement of 14 t axle load wagons should be laid

to the minimum standard prescribed for R1 routes even if these routes are

classified in lower categories.

(b) Concrete

sleepers, wherever provided, should have a minimum ballast cushion of 250 mm.

(c) New rails

should be laid as LWR and concrete sleepers should be used for LWR as far as

possible.

(d) Released

rails of a higher section of (up to 90 R) may be used if the prescribed

sections of rails are not available.

Released

BG CST-9 (Central Standard Track, 9th series) sleepers (90 R) may be used for

secondary renewals on Q and all other routes of MG.

Related Topics