Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Track and Track Stresses

Forces Acting on the Railway Track

Forces Acting on

the Track

A rail is

subjected to heavy stresses due to the following types of forces.

(a) Vertical

loads consisting of dead loads, dynamic augment of loads including the effect

of speed, the hammer blow effect, the inertia of reciprocating masses, etc.

(b) Lateral

forces due to the movement of live loads, eccentric vertical loading, shunting

of locomotives, etc.

(c)

Longitudinal forces due to tractive

effort and braking forces, thermal forces, etc.

(d)

Contact stresses due to wheel and rail

contact.

(e)

Stresses due to surface defects such as

flat spots on wheels, etc.

1

Vertical Loads

Dead load of

vehicles at rail-wheel contact

The value of dead load is usually taken from the

axle-load diagram. It is, however, brought out that for various reasons the

actual wheel loads, even in the static state on a level and perfect track, may

be different from the nominal values. Cases have sometimes come to notice where

a steam locomotive had a higher axle load than the nominal load or had

different right and left wheel loads.

Dynamic augment

of vertical loads

On

account of vertical impact due to speed and rail vibrations, etc., the dynamic

load is much more than the static load. The dynamic wheel load is obtained by

increasing the static wheel load by an incremental amount given by the speed

factor. Till 1965 Indian Railways used the 'Indian Formula' for calculating the

speed factor. This formula is the following:

where

V is the speed in km/h.

At

a speed of 60 mph, the Indian formula gives a speed factor of 55%, whereas the

German formula, as used by RDSO, gives a speed factor of 30%. Investigations

have been carried out by RDSO and different values of speed factors have been

recommended for different types of vehicles running at different speeds.

Hammer blow

effect

The

centrifugal forces due to revolving masses in the driving and coupled wheels of

a locomotive, such as crank pins, coupling rods, and parts of the connecting

rod, are completely balanced by placing counterweights near the rim of the

wheel, diametrically opposite to the revolving masses. The reciprocating masses

of the piston, piston rod, cross head, and part of the connecting rod, by

virtue of their inertia and oscillatory movement, produce alternating forces in

the direction of the stroke and tend to cause the locomotive to oscillate

sideways and nose across the track. In order to reduce this nosing tendency, a

weight is introduced onto the wheels at the opposite side of the crank. The

horizontal component of the centrifugal force of this added weight balances the

inertial force in the line of stroke, but the vertical component throws the

wheel out of balance in the plane perpendicular to the line of stroke. The

vertical component of the centrifugal force of the weight introduced to balance

the reciprocating masses causes variation in the wheel pressure on the rail,

and is called the hammer blow. The heavier the weight added to balance

the reciprocating masses, the greater the hammer blow.

The

hammer blow effect occurs only in the case of steam locomotives. The hammer

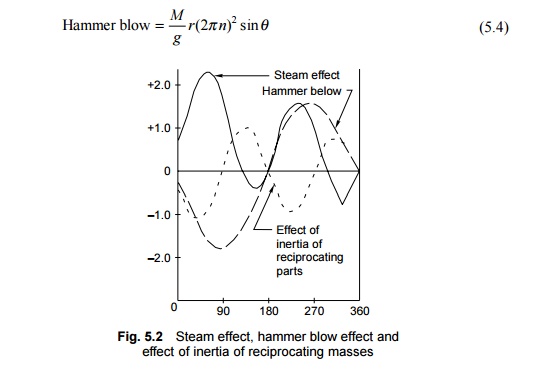

blow can be calculated as follows (Fig. 5.2):

where

M is the net overweight in lbs, r is the crank pin diametre in

ft, n is the number of revolutions of the wheel per second, and ?

is the crank angle.

Steam effect

A

steam locomotive works by converting coal energy into steam energy. Steam

pressure acts on the piston and is transmitted to the driving wheels through

the crank pins and connecting rod. The vertical component of the crank pins and

connecting rod is at an angle to the piston rod. Its value is given by the

formula

where

L is the length of the connecting rod in inches, h is the height

of the cross head above the centre line of the driving wheel in inches, and ?

is the crank angle, i.e., the angle traversed by the crank since the beginning

of the stroke.

The steam effect (Fig. 5.2) does not scynchronize

with the hammer blow effect due to overbalance and is additional to the hammer

blow only during some part of the revolution of the crank shaft.

Inertia of

reciprocating masses

The

reciprocating masses, due to their inertia and acceleration, alter the forces

on the piston, and hence the force in the connecting rod is also affected

during the revolution of the wheel.

where

M is the mass of the reciprocating parts, L is the length of the

connecting rod, n is the number of revolutions per second, h is

the height of the cross head above the centre line of the driving wheel, and ?

is the crank angle.

The maximum combined force of the hammer blow, the

steam effect, and inertia for each driving wheel and the hammer blow effect of

the coupled wheels do not act simultaneously due to the phase difference in the

angular position of the counterweights in the coupled and driving wheels. The

maximum combined effect of these forces is obtained by summing up the three curves

for one complete revolution of the wheel.

Bending stresses

on the rail due to vertical loads

The

general theory of bending of rails is based on the assumption that the rail is

a long bar continuously supported by an elastic foundation. Due to vertical

loads, the rail is subjected to bending or flexural stresses. The bending

stresses that a rail is subjected to as a result of vertical loads are

illustrated in Fig. 5.3. The theory of stresses in rails takes into account the

elastic nature of the supports. Based on this theory, the formula for bending

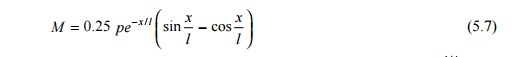

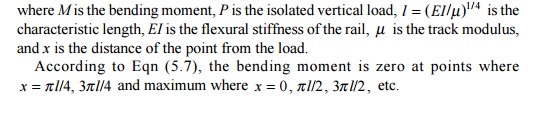

moment is

where M is the bending moment, P is the

isolated vertical load, l ? (EI/?)1/ 4 is

the characteristic length, EI is the flexural stiffness of the rail, ?

is the track modulus, and x is the distance of the point from the load.

According

to Eqn (5.7), the bending moment is zero at points where x ? ? l /4,

3? l/4 and maximum where x ? 0 , ? l /2, 3?

l/2 , etc.

For calculating the stresses acting on the rail,

first the maximum bending moment caused due to a series of loads moving on the

rail is calculated as per Eqn (5.7). The bending stress is then calculated by

dividing the bending moment by the sectional modulus of the rail. The

permissible value of bending stress due to a vertical load and its eccentricity

is 23.5 kg/mm2 for rails with a 72 UTS.

2

Stresses on the Track

Stresses

on the track due to the various kinds of forces applied on it are discussed in

the following sections.

Lateral forces

The

lateral force applied to the rail head produces a lateral deflection and twist

in the rail. Lateral force causes the rail to bend horizontally and the

resultant torque causes a huge twist in the rail as well as the bending of the

head and foot of the rail. Lateral deflection of the rail is resisted by the

friction between the rail and the sleeper, the resistance offered by the rubber

pad and fastenings, as well as the ballast coming in contact with the rail.

The combined effect of lateral forces resulting in

the bending and twisting of a rail can be measured by strain gauges. Field

trials indicate that the loading wheels of a locomotive may exert a lateral

force of up to 2 t on a straight track particularly at high speeds.

Longitudinal

forces

Due

to the tractive effort of the locomotive and its braking force, longitudinal

stresses are developed in the rail. Temperature variations, particularly in

welded rails, result in thermal forces, which also lead to the development of

stresses. The exact magnitude of longitudinal forces depends on many variable

factors. However, a rough idea of these values is as follows:

(a) Longitudinal

forces on account of 30-40% weight of locomotive of tractive effort for

alternating current (ac).

(b)

Longitudinal forces on account of 15-20%

of weight of braking force of the

locomotive

and 10-15% weight of trailing load.

Tensile stresses are induced in winter due to

contraction and compressive stresses are developed in summer due to

compression. The extreme value of these stresses can be 10.75 kg/mm2

in winter and 9.5 kg/mm2 in summer.

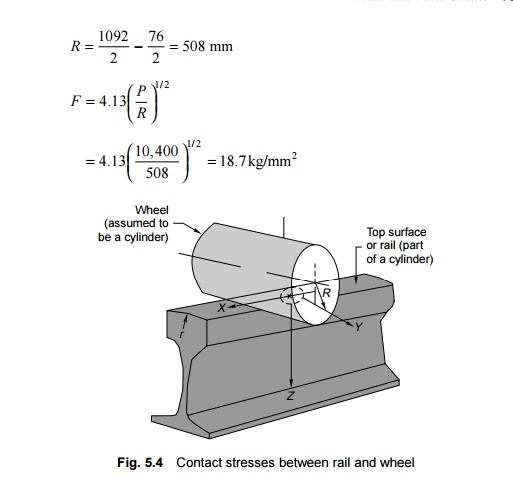

Contact stresses

between rail and wheel

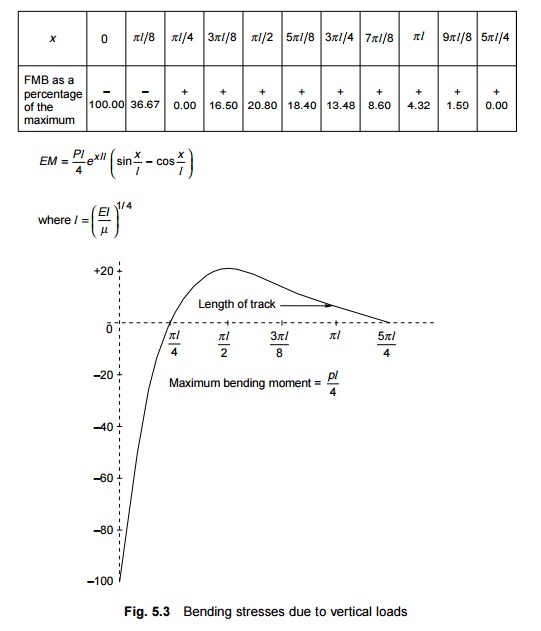

Hertz

formulated a theory to determine the area of contact and the pressure

distribution at the surface of contact between the rail and the wheel. As per

this theory, the rail and wheel contact is similar to that of two cylinders

(the circular wheel and the curved head of the rail) with their axes at right

angles to each other. The area of contact between the two surfaces is bound by

an ellipse as shown in Fig. 5.4.

The

maximum contact shear stress (F) at the contact point between the wheel

and the rail is given by the empirical formula

where

F is the maximum shear stress in kg/mm2, R is the

radius of the fully worn out wheel in mm, and P is the static wheel load

in kg + 1000 kg for on-loading on curves

Contact

stress for the WDM2 locomotive Static wheel load (P)

= 9400 + 1000 = 10,400 kg. Radius of worn out wheel for maximum wear of 76

mm (38 mm radius reduction):

The

contact stress for the WDM2 locomotive as such is 18.7 kg/mm2. The

maximum value is, however, limited to 21.6 kg/mm2, which is 30% of

the UTS value (72 kg/mm2) of the rail.

Surface defects

A

flat on the wheel or a low spot on the rail causes extra stresses on the rail

section. Empirical studies reveal that an additional deflection of about 1.5

times the depth of the flat or low spot occurs at the critical speed (about 30

km/h). Additional bending moment is caused on this account with a value of

about 370,000 kg cm for the BG group A route with the WDM4 locomotive.

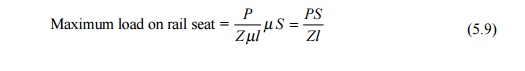

Stresses on a

sleeper

The

sleepers are subjected to a large number of forces such as dead and live loads,

dynamic components of tracks such as rails and sleeper fastenings, maintenance

standards, and other such allied factors. Based on the elastic theory, the

maximum load on a rail seat is given by the following formula:

where

P is the wheel load, µ is the track modulus, S is the

sleeper spacing, l is the characteristic length, and Z is the

modulus of the rail section.

The maximum load on the

rail seat is 30%-50% of the dynamic wheel load, depending on various factors

and particularly the packing under the sleeper.

The distribution of load under the sleeper is not

easy to determine. The pattern of distribution depends on the sleeper as well

as on the firmness of the packing under the sleeper. As the ballast yields

under the load, the pressure under the sleeper is not uniform and varies

depending on the standard of maintenance. The following two extreme conditions

may arise.

End-bound

sleeper The newly compacted ballast is well compacted under

the sleeper and the ends of the sleepers are somewhat hard packed. The

deflection of the sleeper at the centre is more than that at the ends.

Centre-bound

sleeper As trains pass on the track, the packing under the

sleeper tends to become loose because of the hammering action of the

moving loads. The sleeper thus tends to be loose under the rail seat.

Alternatively, due to defective packing, the sleeper is sometimes hard packed

at the centre.

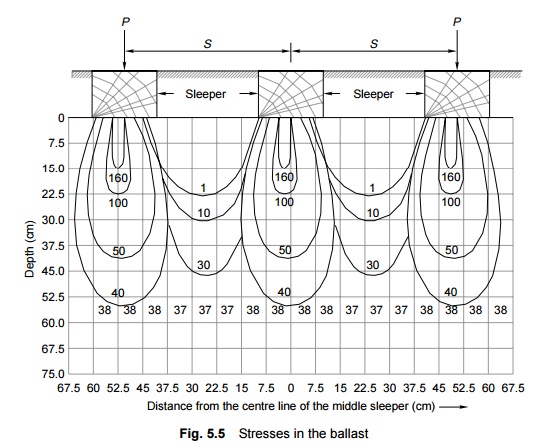

Stresses on

ballast

The

load passed onto the sleeper from the rail is in turn transferred to the

ballast. The efficacy of this load transmission depends not only on the

elasticity of the sleeper but also on the size, shape, and depth of the ballast

as well as the degree of compaction under the sleeper. Professor A.N. Talbot

has analysed the pressure distribution in the ballast under the sleeper and

investigations reveal that the pressure distribution curve under the sleeper

would be shaped like bulbs as shown in Fig. 5.5.

The

following are the important conclusions drawn from Fig. 5.5.

(a)

The pressure on the sleeper is maximum

at the centre of its width. This pressure decreases from the centre towards the

ends.

(b)

The vertical pressure under the sleeper

is uniform at a depth approximately equal to the spacing between the sleepers.

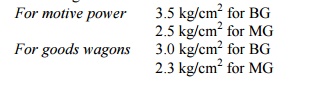

Pressure on

formation or subgrade

The

live as well as dead loads exerted by the trains and the superstructure are

finally carried by the subgrade. The pressure on the subgrade depends not only

on the total quantum of the load but also on the manner in which it is

transferred to the subgrade. The spacing between the sleepers; the size, depth,

as well as compaction of the ballast under the sleeper; and the type of

subgrade play an important role in the distribution of pressure on the

subgrade.

The values of maximum formation pressure permitted

on Indian Railways are the following:

For

motive power

For

goods wagons

Relief of

stresses

A

train load consists of a number of wheel loads close to each other which act

simultaneously on the rail. A single isolated wheel load creates much more

bending moment in the rail as compared to a group of wheel loads, which on

account of the negative bending moment under adjacent wheels provide what known

as a 'relief of stresses'. The rail stresses in this case are comparatively

smaller. The value of relief of stresses depends upon the distance of the point

of contraflexure of the rail and the spacing between the wheels, but its value

can be as high as 50%.

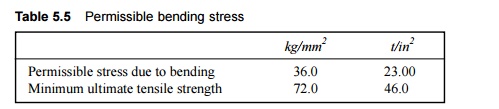

Permissible

stresses on a rail section

The

permissible bending stresses due to vertical load and its eccentricity, and

lateral load on a rail section on Indian Railways is given in Table 5.5.

Table

5.5 Permissible

bending stress

The

stresses on a rail are measured by any of the following methods depending upon

the facilities available.

(a)

Photo-elastic method

(b)

Electric resistance strain gauge method

(c)

Method employed using special test frame

At present, Indian Railways mostly uses the electric

resistance strain gauges for measuring rail stresses.

Whenever

a new locomotive or rolling stock design is introduced on the Railways, a

detailed study is carried out followed by field trials to ensure that the

permitted speed of the new locomotive or rolling stock does not cause excessive

stresses on the track. The same stipulations are made whenever there is an

increase in the speed or axle load of the existing locomotive or rolling stock

design.

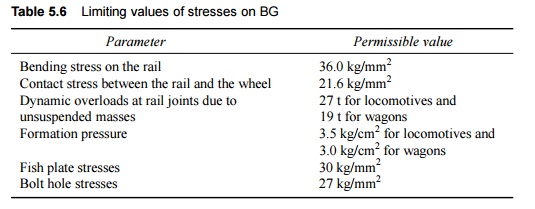

The various parameters and their limiting values

required to be checked for BG are given in Table 5.6.

Table

5.6 Limiting values

of stresses on BG

Related Topics